“Data is everything” has become quite the cliché over the years, but to Bob VanCoillie, it is everything.

The sheer volume of molds for products the Consumer Division of Johnson & Johnson handles globally demands more and more data management, offering a challenge and opportunity to mold builders and molders. Photo Credit: Thinkstock

As senior manager of mold management for the Consumer Division of Johnson & Johnson, VanCoillie manages the division’s mold portfolio, which at the time of this writing was almost 1,700 molds globally. As you can imagine, this comes with several challenges, of which data is one. Other challenges for VanCoillie include access to a limited number of mold and molding process industry experts to facilitate proper execution of a global mold management program.

Welcome! You’ve unlocked premium content.

This is where the expertise of Coast Systems comes into play. The Coast team, led by President Jerry Sherman, supports OEMs globally with the lifecycle management of molds. In Johnson & Johnson’s case, that entails serving as the execution arm to what VanCoillie does, but across the globe.

Before seeking outside help, VanCoillie used a traditional lifecycle management strategy — what hat he describes as capturing “the when, the what and the how” based on the use of mechanical cycle counters and physical on-site mold assessments to identify proper maintenance needs. The problem is that the OEM or owners of molds that place the tooling in third-party manufacturers, often do not have access to the data associated with mold condition or performance, requiring them to collect information by word of mouth or physical assessment. However, this strategy does not cut it when you have a global portfolio of molds responsible for ensuring a stable supply chain.

A traditional approach to lifecycle mold management presents a number of risks and reliance on others in the supply chain for valuable information about tooling performance and condition. Bob VanCoillie, the senior manager of mold management for the Consumer Division of Johnson & Johnson, decided it was time to change to a digital approach. Photo Credit: Adobe Stock.

“You can’t physically assess every mold in every location every year,” VanCoillie says. “So instead, we use a risk-based approach on when to revisit a mold with a physical assessment. We set a baseline with physical assessment checks and follow-ups as needed. Still, this approach requires reliance on information from the molder about performance and condition, which often is not at the frequency or accuracy we’d prefer. It also involves manually loading that information into a mold management system for analysis and decision making.”

Although this traditional way of doing mold lifecycle management is a step in the right direction from a proactive perspective, users still depend on the molder instead of having data at their fingertips. Plus, this approach yields inefficiencies and ineffectiveness in lifecycle and performance management, maintenance planning, capital budget planning, goal setting and business continuity.

In a nutshell, from a general partnership and contractual perspective, incentivizing molders and mold builders to improve OEE or production levels with lifecycle management digitalization that creates feedback loops between the mold builder, molder and OEM is a win-win.

VanCoillie decided to make a change. He started with a focus on digitizing cycle count information, which is critically important in managing mold condition, but does not take advantage of the digital capabilities and technology that now exists within the industry. Now, VanCoillie is taking the mold digitalization efforts to the next level to find a solution for these five challenges presented by OEM management:

- How do we unlock additional value within the mold portfolio?

- How do we improve lifecycle management effectiveness?

- How do we proactively impact and minimize business continuity risk?

- How do we improve speed to market?

- How do we improve end-to-end supply chain performance?

IIoT Technology and Tooling Digitization

The answer was adopting Industry 4.0 and Industrial Internet of Things (IIoT) concepts. VanCoillie explains that Industry 4.0. is a more comprehensive, interlinked approach to manufacturing. It brings together the physical with the digital and improves collaboration and access across departments, partners, vendors and people. It empowers companies to better control and understand every aspect of their operation and enables them to leverage instant data to boost productivity, improve processes and drive growth.

According to VanCoillie, IIoT refers to connections between people, data and equipment in manufacturing. “Industry. 4.0 is a manufacturing philosophy driven by technology like IIoT but with a broader scope. IIoT is manifested in equipment, whereas Industry 4.0 is manifested by buy-in among company management and leadership.”

Since 2019 the moldmaking and plastics industries have moved closer to adopting IIoT as more and more technology suppliers have come to the table with digital solutions and approaches to mold management, many of which are in the early development phase. “The critical point is that there are many different opportunities that IIoT gives to the OEM, and without embracing IIoT, many mold builders and molders miss new business opportunities or lose current customers by lacking the realization that adoption of Industry 4.0 and IIoT offers a competitive advantage that attracts OEMs,” VanCoillie says.

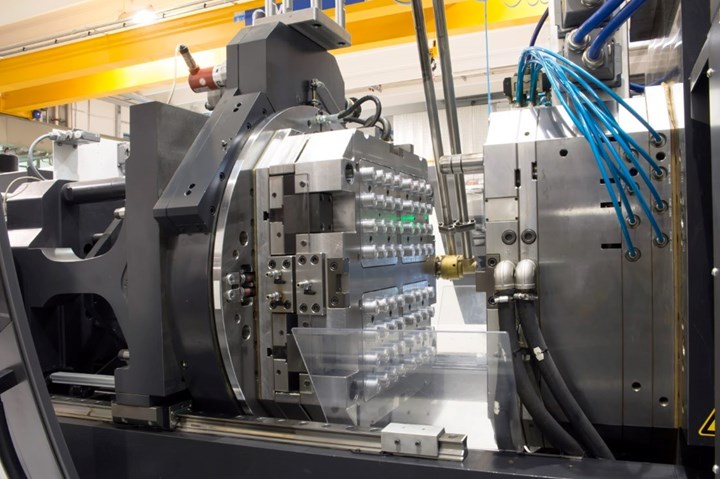

Applying Industry 4.0 and IIoT concepts to its mold manufacturing process yields better control of the entire operation and instant data to improve productivity. Photo Credit: Johnson & Johnson, Consumer Division.

“If you are dealing with archaic mold management tools and word of mouth, your supply chain is at high risk,” Coast System’s Sherman adds. “We are seeing a trend toward proactive management versus reactive management, which is driving the need for IIoT implementation that gives data access to the OEM, the mold builder and molder.”

Industry 4.0 and IIoT concepts include embedded sensors in a mold, automated data monitoring, and collecting and analyzing performance and lifecycle data elements beyond just mold condition. Examples of these advanced data elements and process monitoring include cycle count, cycle time, mold alignment, cooling performance, active cavitation, humidity/environment, ejection force, clamp force, unscrewing force, melt pressure, process time, venting and embedded cameras.

The technology used to apply these concepts that provides this data helps to manage the overall process for making the molds, which supply necessary components and are responsible for supply chain business continuity. These data points lead to state-of-the-art lifecycle mold management.

“Let’s break down what you get with digital lifecycle mold management,” VanCoillie explains. “First, when it comes to mold performance, you’ll have data to track system performance over extended periods and identify faults and predictive maintenance intervals. For mold condition, you will have data accuracy that empowers artificial intelligence [AI] to define actions for early identification of system degradation that could impact mold health. And, from a process perspective, you will have data to monitor and maintain production quality and process stability and identify poor practices that often occur in plastics manufacturing.”

Putting IIoT into Practice

Here are some examples of what things could look like just by tracking cycle count information and cycle time. One advantage is that users can track actual cycle time versus target cycle time to see what is really happening with the mold in the press.

Tracking cycle count and cycle time data reveals exactly what is occurring in the mold during the molding process. Photo Credit: Johnson & Johnson, Consumer Division.

“Because sometimes the molder may be running at a shorter cycle because they gain advantages in press utilization or they are shortening cycle time artificially, which could lead to a manufacturing issue or potential quality defects,” VanCoillie says. “Or how about runtime versus downtime? Where you see downtime, you will also see differences or issues in cycle time information.”

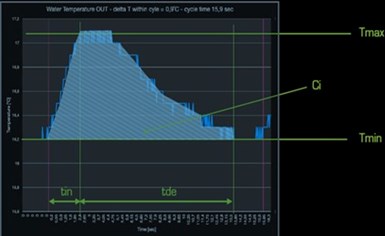

With Industry 4.0 technology a shop can measure water temperature in the mold, which can help establish a baseline for proper cooling temperature and performance. Photo Credit: Johnson & Johnson, Consumer Division.

One example of these advanced data and performance management abilities is that end users can also measure or monitor the water temperature. The curve in the graph on the right represents one profile or one cycle of a mold. The cycle time data is captured by monitoring the thermal cooling performance. The area under the curve graphically represents the thermal properties of the mold.

VanCoillie explains that when this information is coupled with a physical mold qualification, the baseline can be set for proper cooling temperature and cooling performance. Now, performance is detectable and can be used to manage product quality and process stability, and identify potential defects before they leave the molding site and reach the OEM.

From a digitalization mold management system perspective, not every supplier can see everything. “Each supplier and location have access to the tools at their location. So, as we generate and gather data, they can see the same things we see so we can collectively proactively manage the lifecycle and performance of these molds,” VanCoillie says.

Mold builders and molders who use this digitalization technology and adopt IIoT concepts will create competitive advantages and long-term sustainability with OEM partners.

Partnership is the Key to Success

Although it is not typical for someone from an OEM like Johnson & Johnson, that manages molds, to ask the plastics industry to understand their needs and consider adopting IIoT technologies, this is an opportunity for positive change. Mold builders and molders who use this digitalization technology and adopt IIoT concepts will create competitive advantages and long-term sustainability with OEM partners.

According to VanCoillie, the biggest challenge is molder resistance to sharing lifecycle and performance data and concerns over the visibility of hidden costs like piece price and mold cost. He also says that on top of that is the incorrect perspective that cycle time is proprietary information.

“From a cycle time perspective, a molder’s job is conversion. They will develop the process to run your mold, but they have no process without your mold. So, there is no way cycle time can be a proprietary piece of information,” VanCoillie says. “The intention around digitalization initiatives is collaboration and information sharing with molders and mold builders. OEMs don’t want to police molders on price. We want collaboration and information-sharing to help us manage mold lifecycle and performance effectively.”

A big obstacle to adopting a digitalization mold management system is a molder’s resistance to sharing lifecycle and performance data, which VanCoillie believes is based on an incorrect perspective that cycle time is proprietary information. Photo Credit: Adobe Stock

VanCoillie manages a global capital budget consisting of millions of dollars every year and includes new, replacement, refurbished and repaired molds. So, he is looking for accurate capital budget planning, and lifecycle management digitalization is key. It will improve production planning because he can be more predictive based on mold performance and react to production issues more quickly and accurately.

“And OEMs are investing lots of money to get this visibility. It is not something that they take lightly,” Sherman points out. “They are unhappy about not getting the information they want and are ready to invest in getting that data. Every one of our clients has active global projects for enterprise management with this type of information on molds.”

OEMs are investing lots of money to get this visibility. It is not something that they take lightly.

In a nutshell, from a general partnership and contractual perspective, incentivizing molders and mold builders to improve overal equipment effectiveness (OEE) or production levels with lifecycle management digitalization that creates feedback loops between the mold builder, molder and OEM is a win-win. This partnership also offers them a competitive advantage as a preferred supplier to OEMs long into the future.

Considering the strategies being deployed by OEMs to reap cost savings and decrease supply chain risks while managing the lifecycle of their expensive tooling assets, it is highly likely that OEMs will find partners that better align with their corporate strategy of digitization. So, ask yourself, will your business be a part of this trend to new business opportunities or not?

Related Content

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreNavigating Economic Resilience and Consumer Trends

Consumer behavior provides mold builders insight into the evolving market dynamics of goods and services that helps strategic planning.

Read MoreUnited Grinding Precision Summit to Feature 16 Machines, Technical Sessions

The first ever Precision Summit is happening in Miamisburg, Ohio on May 24-25, 2023.

Read MoreHow to Successfully Reshore Tooling

Sloan Valve and Pyramid Molding Group shed light on the dynamics and challenges surrounding the shift toward domestic mold sourcing and the advantages of collaborating with a U.S. supplier to bring tooling back stateside.

Read MoreRead Next

Scholle IPN and Tooling 4.0

The MMT editorial team went onsite at Scholle IPN in Northlake, IL, and talked with Don Smith, senior tooling manager, to learn what Tooling 4.0 means to this company.

Read MoreTooling 4.0: Connecting Industry 4.0 Technology to Your Molds and Molding Process

A packaging supplier applies Industry 4.0 technology to its injection molds so that components talk to each another to understand the dynamics of what is happening inside the mold.

Read MoreInformation Is King—in the Shop and with the Customer—at A1 Tool

This mold builder uses information to improve its operation, molds, and customer service from data collection to data sharing.

Read More