Engineer

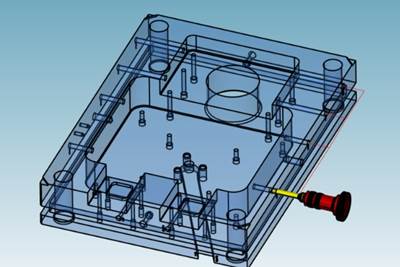

Design Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

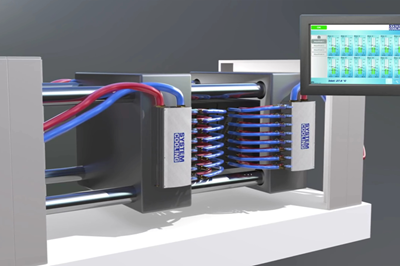

Read More5 Ways to Make Your Tooling Assets Smarter

Global mold monitoring and asset management solutions can maximize productivity and efficiency.

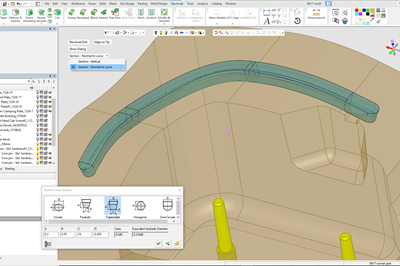

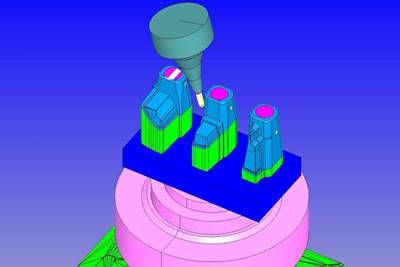

Read MoreMold/Die Software Establishes Higher Productivity for Mold Development

Cimatron powers up version 2024 of its CAD/CAM software, providing stronger core capabilities and new tools for advanced moldmaking with an emphasis on automation, simplified UX, productivity, process management and digital connectivity.

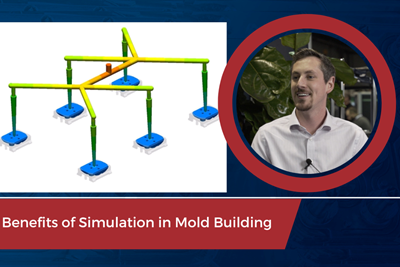

Read MoreVIDEO: Benefits of Simulation to the Mold Builder, Molder

Mike Skaja, a technical sales representative at Sigmasoft Virtual Molding, discusses the value of simulation in the moldmaking process.

WatchCAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreVIDEO: Perspective on A.I. and Mold Design

Bill Genc of TopSolid shares his perspective on the benefits of and barriers to using artificial intelligence in mold design.

WatchTechnology and Sourcing Guide 2023: Software

Design and engineering are essential to building a better and more cost-effective mold with shorter lead times. A variety of software is available to help overcome the daily challenges faced with data, quoting, designing and programming.

Read MoreSurface Finishing Probe Accurately Evaluates Workpiece Surface Finish/Roughness

Soon-to-be-released Verisurf 2024 software will feature a Renishaw Revo SFP2 solution to evaluate a surface finish range of 6.3 to 0.05 micrometers.

Read MoreSoftware Technology to Meet Moldmaking Challenges

Featured in this technology roundup are software solutions that can provide and improve design and manufacturing operations or data management practices during the manufacture of a mold.

WatchFive-Axis Machine With Pallet Changer, 16k-Spindle, Versatile Control Makes More Accurate Molds Faster

The move from three- to five-axis machining with automation reduced setup times and improved surface finishes for this small but mighty Amish mold builder.

Read More