Mold/Die Software Establishes Higher Productivity for Mold Development

Cimatron powers up version 2024 of its CAD/CAM software, providing stronger core capabilities and new tools for advanced moldmaking with an emphasis on automation, simplified UX, productivity, process management and digital connectivity.

Cimatron, CAD/CAM software supplier for the mold and die industry, has released version 2024 of its product with stronger core capabilities, while incorporating new technology through collaboration with Sandvik Coromant. Cimatron 2024 simplifies and automates many tasks for mold designers for higher productivity, and more options for digital connection.

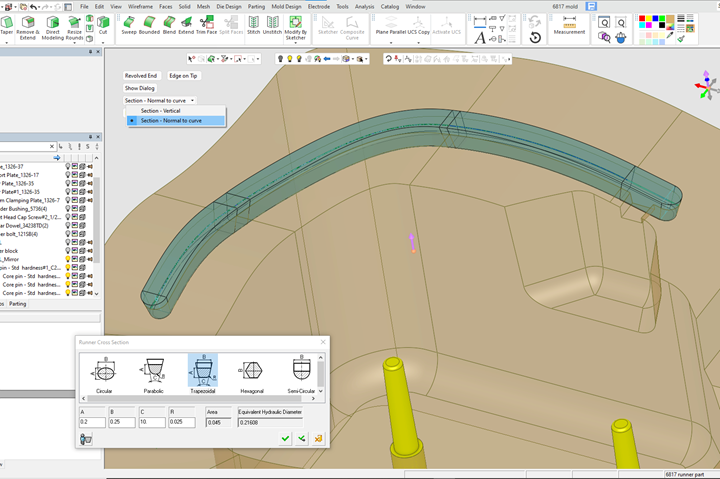

Moldmakers are said to gain powerful CAD enhancements for rib construction with added functionality for working on multiple curves in a single operation and automatically extending rib geometry to part side walls. In addition, Cimatron 2024 can now create partial ribs in complex scenarios where a complete rib cannot be produced. Within mold design, the construction of 3D runners has been improved, providing better design control based upon constant volume, vertical orientation or section orientation.

Electrode design is a critical aspect of the mold production process. Version 2024 includes automation for the Burn Body operation to optimize the electrode body shape, control of electrode extensions and non-cutting rules for manual construction.

Another significant release, an enhanced automatic feed control (AFC) routine, has been redeveloped and optimizes stock removal for roughing operations by automatically controlling the feed rate, resulting in smoother motion, faster machining times, longer tool life and fewer changes on the machine spindle and axes.

A new option for pre-drilling during roughing operations prevents cutters from plunging into blind pockets. Cimatron 2024 also introduces a new three-axis deburring procedure to create chamfers or fillet shapes along sharp edges, as well as five-axis updates that allow the automatic use of remaining stock from previous three-axis operations during roughing, and enhances the five-axis auto tilting feature.

Several notable CAM features involve Cimatron 2024’s On Machine Inspection Probing module, tool paths and implementation of an NC Template Manager. Moreover, the software establishes a direct integration with the CoroPlus Tool Library and TDM tool management system, giving users access to a collection of more than 900,000 cutting tool items.

For a more detailed list of updates, visit Cimatron’s website.

Related Content

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

-

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.