Engineer

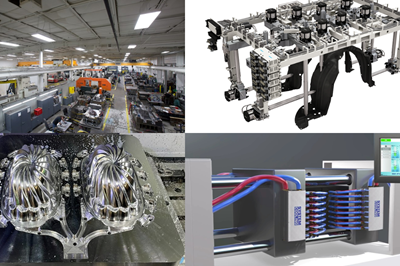

Take Time to Save Time: 6 Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these six steps in the design phase can save three weeks or more in an overall tool build.

Read MoreCAM Automation, Hot Runners, Asset Management & More: The Best of August

What does CAM automation, hot runners, and simulation software all have in common? They are all topics that made it into our top ten most-viewed content pieces in August.

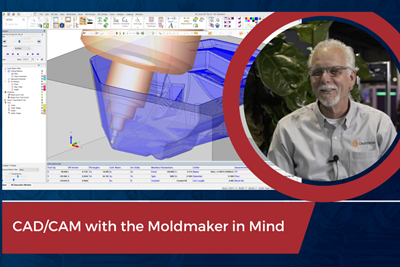

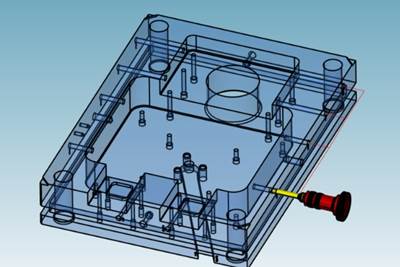

Read MoreVIDEO: CAD/CAM with the Moldmaker in Mind

Ralph Picklo, Director of Sales for Cimatron at CAMBRIO, shares what it means when CAD/CAM is created with the mold builder in mind.

WatchWhat Do the MMT Advisory Board, Leadtime Leaders & MMT Chats Have in Common?...

What Do the MMT Advisory Board, Leadtime Leaders & MMT Chats all have in common?...They were all fan favorites in our top July articles!

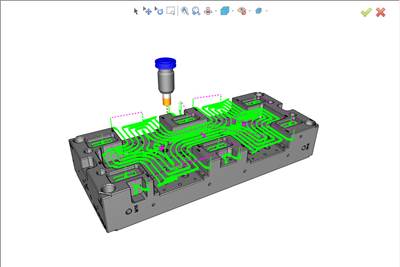

Read MoreCAM Software Release Features Increase Throughput

BobCAD-CAM highlights its CAM software, which offers moldmakers new and improved features such as CAM tree templates and a range of toolpath technologies.

Read MoreDesign Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

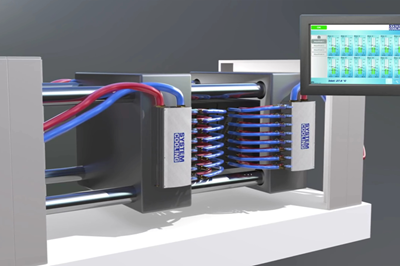

Read More5 Ways to Make Your Tooling Assets Smarter

Global mold monitoring and asset management solutions can maximize productivity and efficiency.

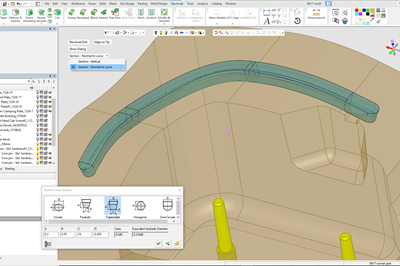

Read MoreMold/Die Software Establishes Higher Productivity for Mold Development

Cimatron powers up version 2024 of its CAD/CAM software, providing stronger core capabilities and new tools for advanced moldmaking with an emphasis on automation, simplified UX, productivity, process management and digital connectivity.

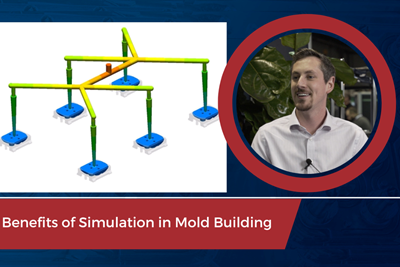

Read MoreVIDEO: Benefits of Simulation to the Mold Builder, Molder

Mike Skaja, a technical sales representative at Sigmasoft Virtual Molding, discusses the value of simulation in the moldmaking process.

WatchCAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read More

.jpg;maxWidth=300;quality=90)