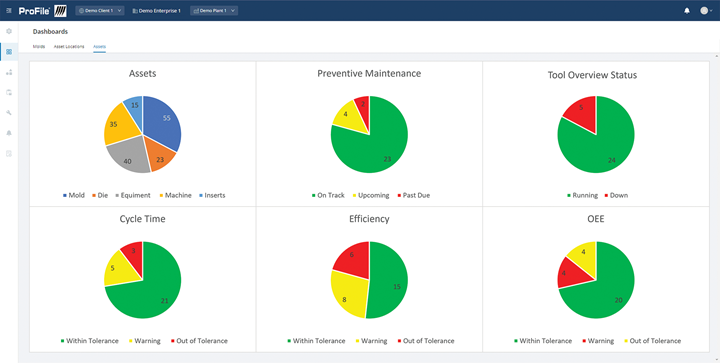

The team at CH3 Solutions in Dalton, Georgia, reviews real-time data to plan daily activities around maintenance and continuous improvement projects, and key performance indicators (KPIs) are monitored to ensure that OEE targets are being met. Photos Credit, all images: Progressive Components

Consider a shift in perspective regarding mold monitoring and performance. Instead of spending time gathering data, why not have the data at your fingertips and then spend your time analyzing that data to improve efficiency?

Today’s shorter timelines, higher demands, supply chain challenges, fewer resources, less technical knowledge and increased remote activity make this focus on efficiency and performance critical.

The first step is to identify your needs. Are you trying to manage, monitor, maintain or maximize mold performance? No matter your answer, there are solutions for every mold builder, molder and OEM that align with your budget, timeline and resource constraints and offer different levels of visibility to match your business needs.

A smart mold can provide data to diagnose problems.

Use Data Proactively

A mold is the most valuable asset a molder or OEM has, so understanding what is happening inside a mold proactively instead of reactively is vital. Shops need to move away from being reactive because isn’t it better to get diagnostics in real time before something unexpected happens? For example, if cycle time or downtime is slowly creeping up, isn’t it better to know ahead of time instead of reacting when something negative occurs and it’s impossible or expensive to fix? Avoiding these unscheduled mold stoppages is critical to maximizing productivity.

This entails making a mold smarter. And let’s face it, everything around the mold is getting smarter, so shouldn’t the mold? The mold is the one piece of the puzzle left to collect vital data and correlate that data to what is happening in the process and with the equipment.

A smart mold can be self-diagnostic with the right technology. Rather than a mold crashing and then finding out too late that something was not performing as it should have, or discovering a problem with the process that yields bad parts, why not put technology in the mold that can report back — either continuously reporting in real time so you can observe trends, or via a sensor that reports a critical failure or out-of-tolerance condition.

Mold data has value to every link in the chain; it just may be a different value for each link. For example, the OEM knows they need the data to ensure their assets are properly maintained and utilized, but they don’t know how to enforce it because of the molders’ reluctance, even as they are concerned about transparency. A molder needs to maintain the mold, to make good parts for the OEM, but also to drive continuous improvement activities and be more profitable. The mold builder wants that information so they can provide feedback, suggest preventative maintenance (PM) strategies and not be held to warranty costs they have no control over.

Technology options to make a mold smarter and improve its performance can interface or be standalone. This decision depends on your business needs, budget, timeline and resources. Here are five ways to make your tooling assets smarter:

1. Asset Tags

Utilize QR code scanning for asset management, which enables location tracking, file sharing and storage of critical documents such as PM records, mold drawings, qualification documents and bill of materials (BOMs).

At a glance, users get a summary overview of their static assets and real-time assets' current status and KPI breakdown.

2. Mold Monitoring

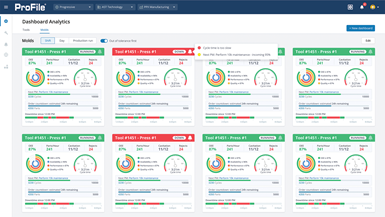

Mold monitoring offers asset management capabilities and basic performance data (cycle times, efficiencies, OEE, local file sharing, flash drive or cloud-based), as well as visibility via production reports and historical data.

For example, say a mold builder quoted a 20-second cycle and recommended maintenance at 50,000 cycles, but the molder runs the mold at 10 seconds nonstop for six months. There will be a problem. They are running faster than it was quoted and running without PMs. This gives the mold builder visibility when issues occur.

Customizable, role-based dashboards give users critical performance data to help drive decisions, continuous improvement activities and mold maintenance.

For the molder, mold monitoring can be a valuable tool also. It provides visibility to their internal operation and gives them the data to know how they are performing (OEE) and where there may be opportunities for optimization. The molder can also pull the production reports and go back to the OEM and say, “We’ve been running this mold and maintaining it within the quoted cycle time, but we’re having problems meeting capacity, or the mold needs refurbishment.” This data becomes evidence that the molder can use to show the OEM that he needs additional capacity or a refurbishment. It’s protection for the molder.

For the OEM, it provides visibility to potential supply chain issues and a central place for all mold and process data to be stored/shared. That visibility ensures that the tool is properly maintained, process changes documented, and mold health and transfers are performed and documented efficiently.

Ultimately, mold monitoring is a communication device that allows the mold builder, molder and OEM data to talk in a common language.

Whether you are a mold builder, molder or OEM, isn’t it time to consider solutions that improve communication across the supply chain and help drive each business forward?

3. Remote Validation

Users can easily hook up a portable version of a real-time monitoring system to a single mold for remote validation or mold qualification. Anywhere in the world, you simply plug this system into the molding press and add power to see data streaming in real time on a secured website, including cycle time, mold stoppages, downtime events, etc.

It is a simple way to qualify a mold without being on site. A moldmaker can offer this remote validation kit to its customers for sampling, moving it from machine to machine, and molders and OEMs can move it from supplier to supplier. The system gathers much-needed data and dramatically reduces the need for multiple run-off iterations. It’s also a cost-effective option for collecting data ensuring adherence to timelines, budget constraints and an efficient allocation of resources.

4. Real-Time Monitoring and Asset Management in One System

This solution offers comprehensive visibility into a user’s global molding operations, providing precise insights into their performance metrics such as reject rates, downtime rates, OEE and more. It provides real-time and historical data, enabling users to gain valuable insights into the overall status of their assets.

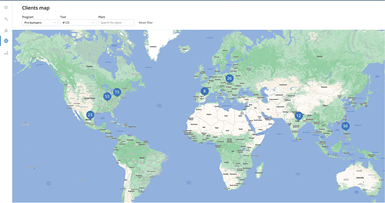

Location and asset tracking using GPS allows users to see the number, types and location of assets on a global map.

In addition, the system incorporates a complete PM and work order system, enhancing transparency and facilitating efficient asset management.

This is where visibility sensitivity comes into play with molders who don’t want to share their cycle time. To combat this objection, the software enables users to turn very specific metrics on and off.

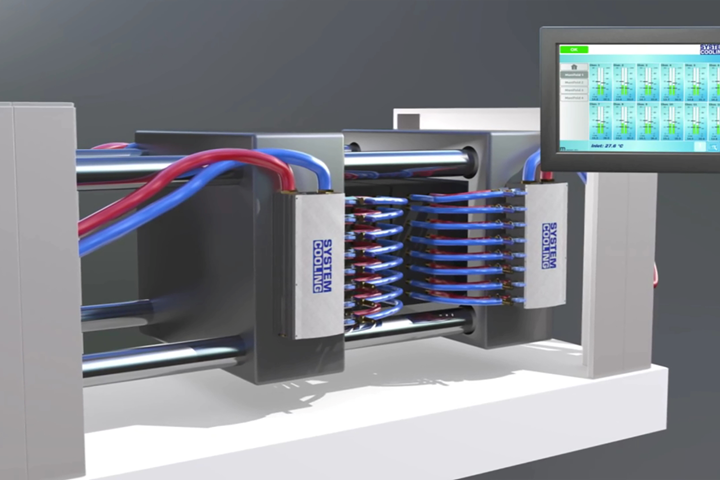

5. System Cooling

This tool involves the measurement of the water flow, temperature and pressure throughout the mold. Cooling is 60% of overall cycle time and that 60% is the most ignored part of the process. Now imagine what cooling optimization can do for a business’ overall profitability.

Just as a mold is the most important part of the supply chain, so is its health and a critical part of mold health is water flow.

For example, a medical customer needed system cooling on six 128-cavity molds and the total investment was around $90,000 for six molding cells. The need was known based on the critical nature of the parts, but the short-term investment was challenging to justify. The customer knew that the systems would justify themselves if they had 12-24 hours of bad production. Three months later, after 2 days of suspect production, they knew the short-term investment would have prevented this failure and moved forward with cooling monitoring.

System Cooling allows molders to collect and view data on the cooling lines within a mold and the cooling parameters during production. Molders using the process monitoring system can view and collect data related to coolant flow, temperature and pressure with information recorded and time stamped for historical tracking.

Whether you are a mold builder, molder or OEM, the ultimate goal is a dependable stream of quality parts on time to deliver the ROI each company needs. It isn’t about “if” you start; it is about “where” you start on the road to making your assets smarter and using that data to increase efficiency and lower non-value-added costs in your organization. The best approach starts with an end goal and a comprehensive step-by-step plan to get there.

Related Content

5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreSurface Finish: Understanding Mold Surface Lingo

The correlation between the units of measure used to define mold surfaces is a commonly raised question. This article will lay these units of measure side by side in a conversion format so that companies can confidently understand with what they are dealing.

Read MoreRead Next

Tooling 4.0: Connecting Industry 4.0 Technology to Your Molds and Molding Process

A packaging supplier applies Industry 4.0 technology to its injection molds so that components talk to each another to understand the dynamics of what is happening inside the mold.

Read MoreMMT Chats: The Rise of Tooling Digitalization

MoldMaking Technology Editorial Director Christina Fuges chats with Bob Vancoillie with the Consumer Division of Johnson & Johnson about OEM corporate initiatives for digitizing tooling.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)