Videos

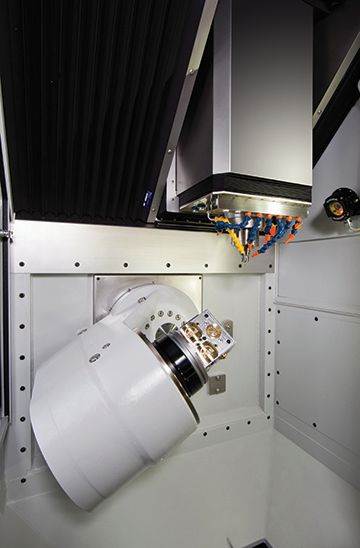

VIDEO: A/C Servo Combination Wrist in Motion

The type of wrist paired with a robot can directly impact mold design.

WatchMachining Complex Contours

Advanced, integrated processor geometry eases processing and predicting of turn-mill contour operations and residual grinding stock allowance.

WatchConsiderations for Assessing Robotics Requirements

Knowledge of part de-molding, end-of-arm tooling construction, part defects caused by the mold-robot interface and available automation options is key for suppliers looking to add greater value.

WatchProductivity Meets Precision

With machine dynamics, mechanical design and thermal stability in control, mold manufacturers can take five-axis machining to the next level.

WatchMold Making: Your Road To Success

Mold Making - Your Road To Success is an educational video targeted at youth who are considering their career choices.

Watch2015 Leadtime Leader Award Winners: Raising the Bar

Winner Cavalier Tool & Manufacturing of Windsor, Ontario and Honorable Mention Dynamic Tool & Design of Menomonee Falls, Wisconsin raise the bar once again in overall innovation, efficiency, quality and commitment in mold manufacturing.

Watch2015 Leadtime Leader Awards Winner: Cavalier Tool & Manufacturing - Setting the Pace Holistically

This mold manufacturer has radically transformed its business by instituting a standardized, flexible process, advanced technology and a people-centric philosophy.

WatchDiamonds in the Roughing

This mold manufacturer discovered significant time and cost savings in a previously unexplored feature of its CAM software.

WatchMold Water System Basics

Molder to moldmaker: “If you want the project, you need to hit the targeted tooling costs.” Then oftentimes the moldmaker builds a tool that fits the budget, but does not have the best performance with regards to water. Here are some basics about the impact of mold's water system.

WatchMachining 3D Parts

For most of the 3D machining required in moldmaking, there are essentially seven steps necessary to achieve the desired results in terms of shape, finish and cycle time.

WatchTooling Up for Challenging Cuts

To maximize quality and repeatability, you need the right cutting tools, especially in challenging applications. Here’s a guide for selecting tools for high-speed tool paths, tight areas, straight walls and graphite cutting.

WatchToroidal Tools for Tight Areas

Toroidal end mill in hardened steel mold machining of helical bores in 54 HRc H13 steel.

Watch