Videos

CAD/CAM Upgrade Boosts Shop’s Efficiency

CAD choice automates and animates, builds customer confidence through communication, and cuts design time in half.

WatchBuilding a Mold in Fewer Setups

Current machine tool technology can reduce complex elements of moldmaking while increasing mold quality and accuracy.

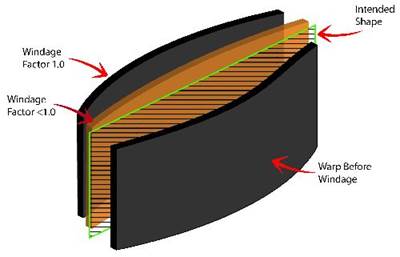

WatchTake the Guesswork out of Windage with Warpage Simulation

Applying Kentucky windage to a mold is not for the faint of heart.

WatchThe Kentucky Windage Solution in Simulation Reduces Warpage

Using simulation to bias your mold and reduce warpage.

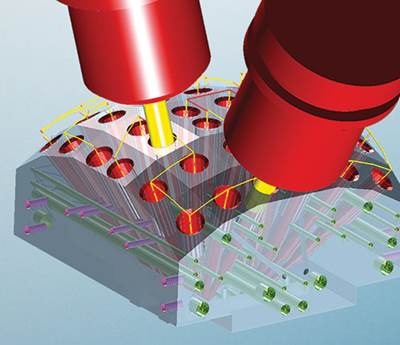

WatchCAM Reduces Cycle Time when Machining Mold Bases

Feature recognition, CAM capabilities and machine controller interaction can reduce cycle time when machining mold bases.

WatchThe Value of Insourcing and Standardizing Component Work

To become more competitive, this mold manufacturer established a components division to build a growing selection of its own mold components.

WatchCarving out Savings at the Front End

Positive-geometry cutting tools help this shop double-down on a key time-saving strategy by reducing machining time on aluminum MUD frame inserts.

WatchPrecision Mold Specialists

Thirty years and counting! Aalbers Tool and Mold Inc. are precision mold and tool specialists.

WatchWhat Machine Consolidation Can Mean for You

How to expand your production and profits in milling and high-speed cutting.

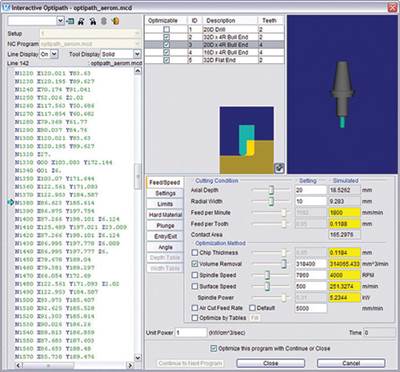

WatchChasing the Perfect Feed Rate

Get more than just reduced machining time with NC program feed rate optimization software.

WatchHigh-Productivity Milling and Boring

Highly accurate and efficient milling and boring capabilities.

Watch

.jpg;maxWidth=400;quality=70)