Videos

Unconventional Strategies for Roughing

Arc of contact and average chip thickness are essential for optimizing rough-machining operations.

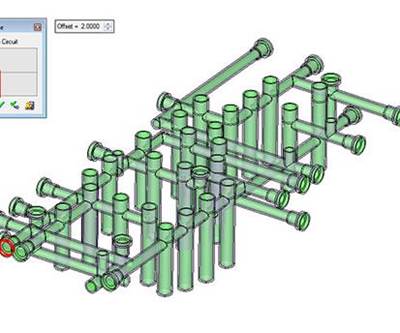

WatchMake Mold Cooling Easy and Effective

Strategies for designing an effective cooling system with less time and effort.

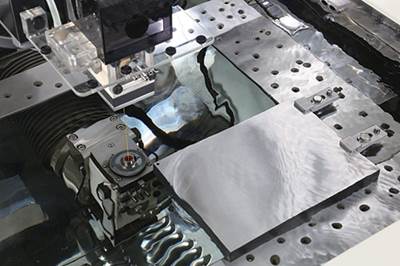

WatchIn-Machine Mold Cleaning

Cleaning mold cavities and vents, including those with complex, tight geometries, is critical to producing quality products.

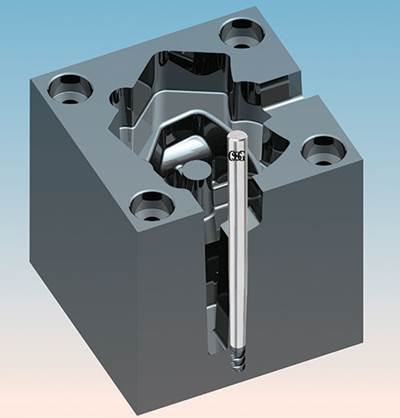

WatchTruly Smart EDM

Think ease of use, ergonomics and expertise when empowering your operators with the right EDM.

WatchUser-Friendly EDM Control Technology

Wire EDM machines have taken ease-of-use to a new level, by being equipped with the next evolution of advanced machine control.

WatchNew Strategies for High-Speed Roughing

An alternative approach to this application produces tool paths with a controlled engagement angle.

WatchHigh Speed Roughing Tool Path Strategy

The amount of time that can be saved with the new roughing strategies varies with the material and shape being cut, and the machine tool and cutting tools being used. A series of trials1 has shown that a time savings of at least 40 percent is achievable.

WatchHybrid Geometry Machining in Action

Hybrid quad-force geometry is a combination of high-feed geometry, variable flute geometry, variable helix geometry and offset geometry that gives programmers and machinists the flexibility to side/slot, high-feed, trochoidal and plunge/variable plunge mill with one tool.

WatchControlling Cutting Tool Cost with Hybrid Geometries

Why purchase redundant tooling and risk losing control of your manufacturing costs? Hybrid cutting tool geometries allow you to perform multiple machining applications with one tool.

WatchA Look Inside Managing Mold Shop Work Flow

Moldmaker discovers the ease and power of the cloud, by using it to better predict, schedule and manage job flow.

WatchSimplifying Work Flow Management

This moldmaker discovered how new business strategies can help better predict, schedule and manage job flow, especially in the cloud.

Watch