Videos

Dare to Lead

What does it mean to be a Leadtime Leader? It means setting a higher standard for overall innovation, efficiency, quality and commitment in mold manufacturing.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreManaging all That Data

Product data management may have a bad rap, but making it a priority rather than an afterthought can help make the most of your design and machining information.

Read MoreHand Scraping Craftmanship

Hand scraping is the process of using either a manually or motorized-driven scraping blade to remove very small amounts of metal from a precision surface to eliminate high spots left behind from the machining process.

Read MoreCutter Sets New Standard for Heavy Hogging

A recent roughing application shattered this moldmaker’s expectations about the stability of a large face mill in long-reach contouring operations.

Read MoreGet the Wear Out

An effective way to extend mold life and ease mold warranties is to better manage mold cleaning techniques.

Read MoreFace Mill Shatters Expectations

This footage depicts Ingersoll's Gold-QuadF in action at Nova Tool and Mold, where personnel were surprised by the large face mill's ability to perform well in contouring as well as facing applications.

Read MoreAirfloat Quick Mold-Change System in Action

Make efficient use of your presses with an Airfloat Quick Mold-Change System.

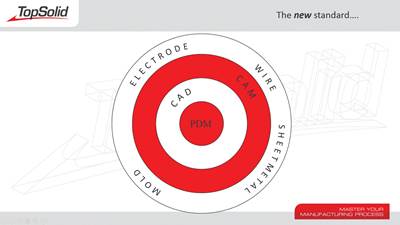

Read MoreRedefining CAM Technology for Moldmakers

Tool paths that dynamically adjust tool motion allow faster, safer machining without the need for high-speed equipment.

Read MoreVMC Enables Faster, Smoother Cutting

Higher spindle speed and sufficient CNC look-ahead improve efficiency, tool life and surface finish in the manufacture of foam injection molds.

Read MoreCryogenic Basics

Cryogenic machining technology milling fluid end component made of 4340 high alloy hardened steel.

Read MoreCryogenic Machining Eliminates Moldmaking Conundrum

As moldmaking material gets harder and more expensive to cut, suppliers are “caught between a rock and hard metal,” balancing production costs with customer needs. Cryogenic machining with through-tool liquid nitrogen makes production of longer-lasting molds efficient and affordable.

Read More