Tool Steel

Tooling Boards Offer Uniformity/Stability in Prototyping and Tooling Applications

A very uniform, dimensionally stable, urethane-based series of tooling boards has been developed for use in prototype, composite tooling, foundry pattern, fixture and other applications.

Read MoreSpray Form Technology Fills the Gap in Plastic Mold Tooling

New method for producing steel yields significantly better overall tooling economy.

Read MoreBreaking the H-13 Stereotype For the Common Mold

A look at the new grades and steel making practices that are available to address the day-to-day issues that occur in the operation of a mold.

Read MoreThe Value of a Shop’s Welding Policy

To put the appropriate welding policy in place, you need to choose the right welder—someone who is familiar with tool steel and has a working knowledge of molds.

Read MorePart Three of a Three-Part Series Five Steps for Improving Your Shop’s Maximum Productivity

An explanation of the differences between high-speed machining and conventional machining; and, general thoughts on when to high speed machine and heat treat versus hard milling.

Read MoreLooking Sharp

Advancements in cutting tool/toolholder construction yield better stability and higher accuracy to achieve greater feedrates and increased productivity.

Read MoreIt's a Material World

Strength, hardness and machinability are the common buzzwords that come into play when examining the new materials on the market.

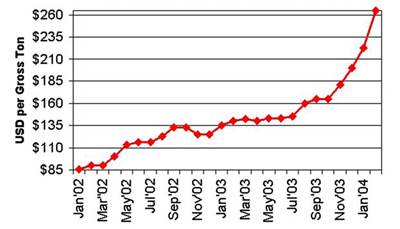

Read MoreThe Rising Cost of Tool Steel

MoldMaking Technology's 2003 and 2004 Leadtime Leaders weigh in on the effects of the tool steel price increase.

Read MoreSteel Update: The Rising Cost of Steel

Structural change in the steel industry will change pricing patterns for moldmakers in the next several years.

Read MoreSteel Wars: Aluminum Versus Steel

Conventional steel tools have some obvious advantages in the mold industry but aluminum proves to be gaining some strength in the competition.

Read More