Celebrating a Solution for a Sticky Situation

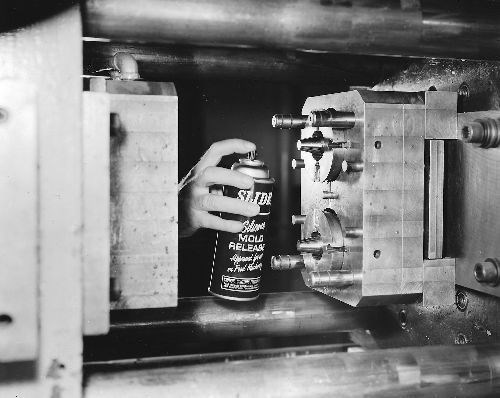

In MMT we focus a lot on surface treatment challenges and solutions, so this little tidbit caught my attention. Life changed 60 years ago for a man selling steel to mold builders when the need for "unsticking" plastic parts from molds revealed an opportunity for a new product--silicone oil in an aerosol can. This evolved into the first mold release – and foundation – of the new Percy Harms Corporation, predecessor of Slide Products, which celebrates its 60th anniversary in the injection molding industry this year.

In MMT we focus a lot on surface treatment challenges and solutions, so this little tidbit caught my attention.

Life changed 60 years ago for a man selling steel to mold builders when the need for "unsticking" plastic parts from molds revealed an opportunity for a new product--silicone oil in an aerosol can. This evolved into the first mold release – and foundation – of the new Percy Harms Corporation, predecessor of Slide Products, which celebrates its 60th anniversary in the injection molding industry this year.

It was 1953 when young Percy Harms was selling steel to mold builders and saw a need in the then-new plastics and injection molding industry to help them prevent plastic parts from sticking in the mold. That need drove Percy to approach a cousin working in the aerosol industry about putting silicone oil in an aerosol can.

To commemorate Slide’s 60 years, the company is having two new iPad giveaways. To participate, qualified industrial users should click here and correctly answer one trivia question about Slide Products and submit contact info before June 30. A second question will be posted from July 1 to December 15, 2013. The first winner will be announced in July, and the second before year end. Only one entry per person per giveaway is allowed.

“These giveaways are our way of thanking customers for 60 years of success,” says Slide Products President Michael Muth.

Slide explains, that as the company’s sales grew, so did its staff, with sons Jim and Henry joining Percy’s business in 1963, and the company moving in 1974 to its current corporate and manufacturing facility in Wheeling, IL. In 1993, the company changed its name to Slide Products, adopting the name of one of their most popular product lines and the nickname used by its customers and distributors.

“After the EPA issued its final assessment in September 2011 characterizing trichloroethylene (TCE), one of the most widely used chlorinated solvents nationwide, as carcinogenic, we eliminated not just TCE, but all chlorinated solvents from our products,” says Michael. Not a single product in the company’s entire line has any type of chlorinated solvent.

They also maintain a close relationship with customers and distributors by employing an extensive network of locally based distributors worldwide who know customers by name and can provide products and technical support quickly and easily.

So help them commemorate by taking your turn at some trivia!

Related Content

-

How to Lower Cycle Times With the Right Tool Steel

Combining excellent mechanical properties, high wear resistance and high thermal conductivity in a specialty tool steel yields cycle time reduction.

-

Qualified Tool Steel Enhances Thermal Transfer, Long Tool Life

Next Chapter Manufacturing has successfully qualified HTC-45 tool steel, an optimized version of H13, to support better thermal transfer and faster cycle times for molders and die-casters.

-

VIDEO: Qualifying Modified H-13 for 3D-Printed Tooling

Next Chapter Manufacturing and International Mold Steel discuss their partnership to qualify a modified H-13 for tooling applications.

.jpg;maxWidth=300;quality=90)