Tool Steel and Aluminum Staying Strong

A roundtable of mold material suppliers discuss how new offerings result in easier machinability, better weldabilty, increased strength and improved surface hardness.

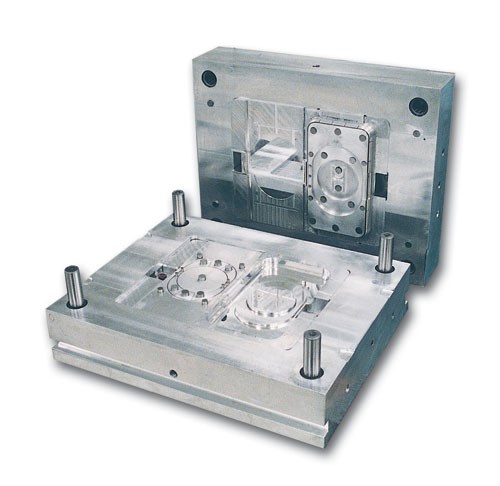

Mold material manufacturers continue to develop new tool steels and alloys that allow mold manufacturers to get the job done as quickly and efficiently as possible. Increased surface hardness, higher strength, improved corrosion resistance, easier machinability and higher polishability are all prevalent in these offerings. And, aluminum is continuing to emerge as an alternative for some tool steels—offering time- and cost-savings for certain applications.

A number of leading mold material manufacturers and suppliers discuss trends and challenges as well as the advantages new materials and alloys offer in terms of lower part costs due to decreased cycle times and less wear and tear on the molders' molding machines.

Questions and Challenges

According to Patricia Miller, Sr. Technical Manager of Bohler-Uddeholm U.S. (Elgin, IL), moldmakers commonly ask for assistance in resolving issues—whether it is corrosion, cracking, cycle time reduction or wear-related phenomena. Additionally, moldmakers are looking for guidelines in heat treatment of the company’s alloys, which Bohler publishes on its website. “They would like to have comparisons of our steels in terms of the most fundamental requirements: corrosion resistance, wear resistance, polishability, texturability, weldability and cracking resistance,” Miller states.

Weldability is also on the minds of moldmakers interested in materials that ThyssenKrupp Materials NA Copper & Brass Sales Div. (Southfield, MI) provides. “The question about aluminum mold materials that we hear most often is in relation to the weldability of these high strength alloys,” states Douglas Zeug, Marketing Manager-Mold Materials. “We do have prototype weld wire that is showing very favorable results.”

Questions about aluminum materials are also fielded at Yarde Metals (Southington, CT). Director of Midwest Sales Jay Gawitt reports the following questions are asked of the company: what cycle time improvements can be expected on an aluminum mold versus a steel mold; what is the lifteime of the tool, can it be welded, and how can mold repairs be performed?

At Schmolz + Bickenbach USA, Inc. (Carol Stream, IL), common questions regarding stainless steel pre-hardened mold base materials are how well the material machines and the stability of the material (resistance to distortion while machining complex geometry), notes John Stocker Regional Sales Manager USA.

Jason Carter, Sales & Marketing Manager, AMPCO Metal, Inc. (Arlington Heights, IL) says that the company addresses questions relative to the company’s capabilities and alloy offerings.

Mold Material Advancements

Miller of Bohler-Uddeholm sees a move toward stainless alloys with enhanced corrosion resistance and wear resistance. “For example, in medical molds where cleanroom environments are required, these requirements are critical,” she states. “It is also found in precision packaging applications. We also see requests for stainless alloys that are prehardened, which the customer can just machine and put into operation for short- to medium-production run applications. It is also required for molding corrosive materials like PVC in both injection molds and plastic extrusion tooling. Larger tools, requiring corrosion resistance, are also a main focus for this area.”

Additionally, Miller notes the company sees a need for high strength tool steels with good wear resistance, weldability and polishability, for use in applications like thermoset plastic molding with abrasive fillers. “There is a continuous need to try to reduce cycle time, particularly for high-volume part production,” Miller elaborates. “Customers are looking to conformal cooling concepts, and steels with better heat diffusivity. Steels with better thermal conductivity and high toughness, will also permit the mold designer to move cooling channels closer to the surface—further reducing cycle time.”

To address these challenges, Bohler-Uddeholm has introduced a new stainless grade for cores1, with very good corrosion resistance, and high hardness, up to a hardness of 60 HRC, Miller says. The company is also stocking a grade2 that features good corrosion resistance that is prehardened to 40 HRC, in flats up to 16 inches thick.

Over at Schmolz + Bickenbach, it took more than two years for the company to achieve the “desired properties” of its newest tool steel3, according to Ted Callighen, Regional Sales Manager Canada. “A particular challenge was to homogenize the steel’s structure with the correct proportion of sulfur to optimize the machining properties of the steel without impairing its performance characteristics,” he explains.

The reengineering of this material offers the thin wall tooling industry a new alternative to the existing stainless steel mold base materials available today, Stocker of Schmolz adds. “The homogenous structure ensures greater stability for complex geometry tooling and improved machinability without reducing the corrosion resistance,” he comments.

AMPCO Metal plans to continue to develop its beryllium-free product line. “We see a trend in the U.S. to utilize beryllium-free alloys within the production of molds,” Carter notes. “Developmental production endeavors are underway internally to expand our size offerings in each of our two new alloys4—both round bar and plate thicknesses.”

Aluminum advancements also abound. Gawitt of Yarde Metals believes the most significant advancement in mold materials this year is the continued growth of high strength, highly engineered aluminum alloys being used in place of steel mold applications, particularly in the automotive industry. “As moldmakers continue to gain a better understanding of the advantages aluminum has to offer, we will continue to see tooling conversions in various industries, including automotive, appliance, medical and construction equipment,” he states.

There are significant differences that exist between machining steel versus aluminum, Gawitt continues. “It is very important for the moldmaker/mold designer to understand how these differences will affect the design of their tools and machining of their tools, particularly in how to polish, texture, and repair these materials. However, aluminum offers several advantages over steel, including faster machining, significant cycle time reductions, better thermal conductivity, improved molding machine life, and it is 66-percent lighter than steel.”

Zeug of Thyssen Krupp Materials/Copper & Brass Sales Div. predicts that aluminum will continue to make inroads in the injection mold arena. “Many aluminum molds have exceeded the shot counts desired and been deemed a success,” he says. “Aluminum molds offer savings in both time and cost during the construction, but the real savings is realized by the reduced press time during molding. The lighter weight aluminum mold also reduces the wear and tear on the injection press. The thermal conductivity of aluminum allows the mold change-over time to be reduced, as the mold comes up to operating temperature more rapidly than a steel mold. We will continue to increase our investment in the aluminum alloys for mold construction; and are always reviewing new alternative alloys and producers.”

Clearly, mold material manufacturers and suppliers are staying on top of current industry demands and will continue their quest to introduce materials that feature better weldability, the highest strengths, and improved levels of polishability—adding up to shorter cycle times, less mold maintenance and a higher quality mold

References:

1 Bohler-Uddeholm U.S., Bohler N360 ISOEXTRA

2 Bohler-Uddeholm U.S., Bohler M303 EXTRA

3 Schmolz + Bickenbach USA, Inc., Corroplast FM

4 AMPCO Metal, Inc., AMPCOLOY® 940 and AMPCOLOY® 944

Related Content

Project Reveals Added Benefits of New P20 Grade Steel in Machinability, Cycle Time and No Stress Relief

MoldMaking Technology's Christina Fuges talks with General Motors' Shane Appel about a project testing a new P20 steel grade's dimensional stability.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreVIDEO: AM Powder Addresses Current Inefficiencies, Sustainability and Skills Gap

Steel supplier discusses high thermal conductivity metal powders that also address the skills gaps via user-friendly materials and promote sustainability via durability and higher cycle counts.

Read MoreHow to Lower Cycle Times With the Right Tool Steel

Combining excellent mechanical properties, high wear resistance and high thermal conductivity in a specialty tool steel yields cycle time reduction.

Read MoreRead Next

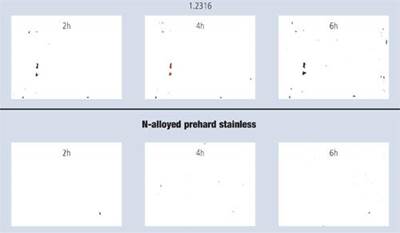

Prehardened Stainless Mold Steel Optimized by Nitrogen Alloying

To prevent the negative effects of microstructural inhomogenities in some tool steel—such as on machinability, polishability, corrosion resistance and mechanical properties—a new alloy has been created with a more homogeneous microstructure.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More