Vacuum Heat Treating of Tool Steels

Tool steel refers to a variety of carbon and alloy steels that are particularly well-suited to be made into tools, however, special attention needs to be paid during their heat treatment so as to achieve the best properties for a given application.

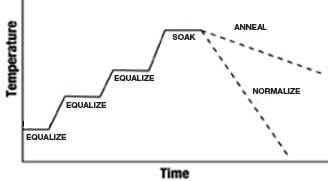

Tool steel heat treatment today is based on a simple premise: to obtain the optimum performance from any given grade, every step of the heat treating process—including stress relief, preheating, austenitizing, quenching and tempering—must be done exactly correct.

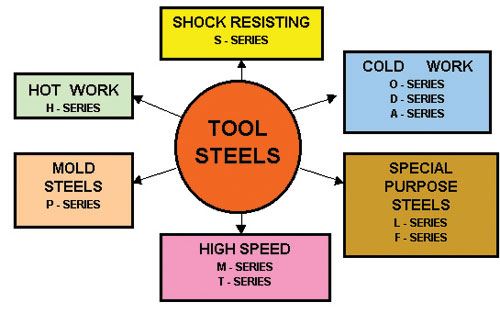

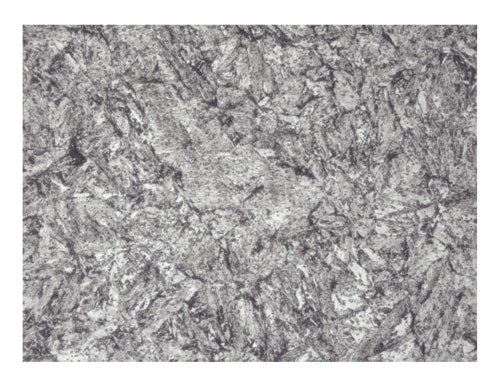

The selection of any tool steel (see Figure 1) depends on a combination of factors including component design, application end use and performance expectation. For any given application the goal of heat treating is to develop the ideal microstructure (see Figure 2) to help achieve the proper balance of desirable properties: hot (red) hardness, wear resistance, deep hardening and toughness:

Tool Steel Characteristic [a] Alloying Element (by potency)

Hot (red) hardness W, Mo, Co (with W or Mo),

V, Cr, Mn

Wear resistance V, W, Mo, Cr, Mn

Deep hardening Mn, Mo, CR, Si, Ni, V [b]

Toughness [c] V, W, Mo, Mn, Cr

This shows the effect of alloying elements on tool steel properties. Notes: [a] Distortion is best managed by additions of: Mo (with Cr), Cr, and Mn; [b] Tool must be austenitized at a high enough temperature to dissolve the vanadium carbide; and [c] Toughness is achieved via grain refinement.

Mold Manufacturing Industry Needs

A key question asked of heat treaters by moldmakers is, “Can I achieve the same microstructure with vacuum hardening as I can with other heat treatment methods, such as salt?” The simple answer is “Yes.”

Advances in vacuum furnace technology—particularly in the area of high gas pressure quenching—produce microstructures with the type and distribution of carbides throughout the matrix equivalent to those microstructures traditionally limited to salt bath heat treating.

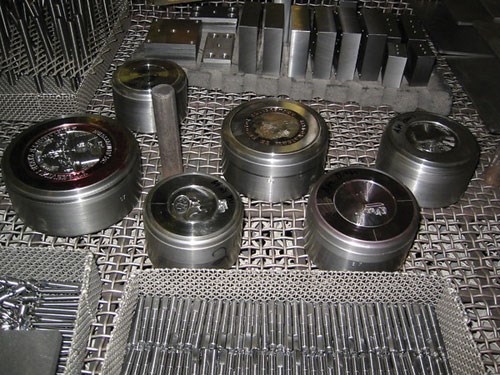

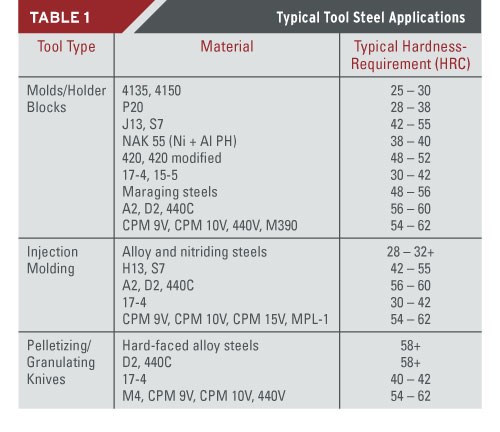

The moldmaking industry requires the processing of a variety of materials, geometries, cross sectional areas and load sizes (see Figure 3). Heat treatment specifications can be extremely diverse. The principal application areas (see Table 1) include plastic processing, hot/warm working steels (e.g. H11, H13), cold working steels (ASP 23, M4, T15, CPM 9V, CPM 10V, CPM 15V) and high-speed steels.

Defining Pressure Quenching

The most common definition for high-pressure gas quenching is accelerating the rate (speed) of quenching by densification and cooling of gas. One of the reasons for the intense interest in this quenching technique is related to improved part distortion with full hardness. A critical concern is to avoid sacrifice of metallurgical, mechanical or physical properties. That is, retain the ability to transform a material to a microstructure that is similar, identical or superior to that of a known quenching medium (e.g. oil or salt). Common quench gases include nitrogen, argon and helium. Hydrogen, although excellent with respect to heat transfer, is seldom used as a quench gas due to safety considerations.

Pressure Levels

Selecting the optimum gas pressure for quenching is highly dependent on a number of factors: material, component geometry, loading, net to gross load ratio, gas parameters and equipment design. Pressure ranges are typically classified as sub-atmospheric, low, medium, high and ultra-high pressure, irrespective of the type of gas used.

Classification Pressure Range bar (psig ) [a]

Vacuum cooling < -0.67 (-9.7)

Sub-atmospheric pressure -0.67 to -0.17 (-9.7 to -2.5) [b]

Low pressure 2 – 4 (29 – 58)

Medium (mid-range)pressure 5 – 9 (72 – 130)

High pressure 10 – 20 (145 – 290)

Ultra-high pressure >20 (290)

Classification of gas quenching pressure ranges. Notes: [a]Gauge pressure (psig) is the measurement of the difference between the absolute pressure and local atmospheric pressure (which can vary due to temperature, altitude and relative humidity); [b] pressure is normally limited to -0.17 bar (rather than 0) to prevent the furnace from reaching atmospheric pressure and the door opening.

Summary

The key to understanding the factors that influence gas quenching is to achieve a balance between the speed of quenching and the uniformity of quenching. The former focuses on maximizing the heat removal rate, while the latter involves uniform heat extraction. In this way, both repeatability (quality) and performance (productivity) will be achieved with an optimized microstructure.

The toolmaker must define his requirements on his P.O. to avoid surprises. Gas quenching should be applied in applications where its advantages outweigh its disadvantages. Having a complete understanding of the performance requirements of the product will help to evaluate which quenching choice is best for the end-use application.

References

Elgun, Serdar Z., Tool Steels, Farmingdale State College (http://info.lu.farmingdale.edu)

Herring, D. H., Gas Quenching, Chapter 19, Vacuum Heat Treatment Series, Industrial Heating, 2011 (in preparation).

Herring, D. H., A Tool Steel Primer: Frequently Asked Questions About Tool Steel Heat Treating, Industrial Heating, July 2010.

Herring. D. H., A Review of Gas Quenching from the Perspective of the Heat Transfer Coefficient, Industrial Heating, February 2006.

Mr. Alan Stone, Aston Metallurgical Services Co., Inc. (www.astonmet.com), private correspondence.

Contributors:

Daniel H. Herring is “The Heat Treat Doctor” ® with The HERRING GROUP, Inc. Patrick McKenna is Vice President of Nevada Heat Treating, Inc. (Carson City, NV).

For More Information:

The HERRING GROUP, Inc.

(630) 834-3017

dherring@heat-treat-doctor.com / dherring@ameritech.net

www.heat-treat-doctor.com

Nevada Heat Treating, Inc.

775-246-1040

patm@nevadaheattreating.com

www.nevadaheattreating.com

Related Content

VIDEO: Qualifying Modified H-13 for 3D-Printed Tooling

Next Chapter Manufacturing and International Mold Steel discuss their partnership to qualify a modified H-13 for tooling applications.

Read MoreWhat You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

Read MoreProject Reveals Added Benefits of New P20 Grade Steel in Machinability, Cycle Time and No Stress Relief

MoldMaking Technology's Christina Fuges talks with General Motors' Shane Appel about a project testing a new P20 steel grade's dimensional stability.

Read MoreAdvancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

Read MoreRead Next

Tool Steel and Heat Treatment, Part 1

An introduction to heat treatment for the moldmaker.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More.jpg;maxWidth=970;quality=90)