Maintain

Seven Habits of Highly Effective Repair Technicians

Effective, efficient mold repair is a unique skill when complemented with knowing what it takes to keep molds running optimally and reliably.

Read MoreBeyond the Classroom: Mold Maintenance Products That Work

Leaving injection mold maintenance to chance is a costly oversight. Using standardized methods of improvement, as explained here, can yield real change to company practices as well as significant returns on a company’s tooling investment.

Read MoreHow to Decrease Your Internal Mold Maintenance Costs, Part 2

A look at the ultrasonic cleaning process in detail, discussing cleaning detergents, process layout and return on investment.

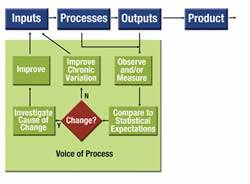

Read MoreStatistical Process Control: Beyond the Data

Statistical process control used correctly allows moldmakers to connect data sources, collect data and issue failure alarms in real-time.

Read MoreHow to Decrease Your Internal Mold Maintenance Costs, Part 1

With an ultrasonic cleaning system, a mold shop can realize savings in cost, time and labor, as long as they are educated on the technology, the cleaning solutions and what works best for their particular situation/environment.

Read MorePolishing Process: Micro Machining Process

MMP, which stands for micro machining process, is a proprietary superfinishing method for metallic parts that delivers consistent, repeatable results using a finely controlled automated process.

Read MoreElectrode Effect on a Quality EDM Finish

The production of fine surface finishes in the cavity does not come with the technological improvements of the EDM sinker unless an electrode material of higher quality is used.

Read MoreDirect Metal Laser Sintering vs. Conventional Tool, Part Two

In this head-to-head comparison, conventional toolmaking seemed to be the superior route to go from a cost, quality and leadtime perspective.

Read MoreBuilding a Better Mold

A look at mold performance and maintenance issues through a few simple reports in the right sequence will allow you to drill down into what the issues are really costing you.

Read MoreFive-Axis Inspection for Moldmakers

Does five-axis inspection offer similar benefits in speed and accuracy for moldmaking operations?

Read More