Direct Metal Laser Sintering vs. Conventional Tool, Part Two

In this head-to-head comparison, conventional toolmaking seemed to be the superior route to go from a cost, quality and leadtime perspective.

Many readers may remember the June, 2008 article where a direct comparison was made between the direct metal laser sintering (DMLS) process to create tooling inserts and conventional CNC and EDM processes to make the same geometry. In this head-to-head comparison, conventional toolmaking seemed to be the superior route to go from a cost, quality and leadtime perspective. Recognizing that a few items were not optimal for the DMLS process on the first go-around, Extreme Tool & Engineering (Wakefield, MI) and Morris Technologies, Inc. (Cincinnati, OH) embarked on a second round and found the results to be dramatically different. Using the same part geometry and steps as before, we successfully demonstrated that DMLS inserts will produce good quality injection molded parts with very competitive cost and leadtimes.

First Round

As was noted in the first article, there were two primary factors that drove the DMLS process to compare unfavorably to conventional tool creation. The first factor was the design of the core and cavity. Although certain elements were incorporated that took advantage of the additive layering manufacturing process of DMLS, such as conformal cooling lines, overall the inserts were designed for traditional moldmaking methods that lead to too much mass and thus additional scanning during the DMLS build. This drove both the time and cost much higher.

The second major factor was the alloy that we used in the first comparison. At the time we were ready to build the DMLS inserts, the MaragingSteel MS1 material was just being released to North America and due to some unexpected delays, we were not able to acquire the MS1 material in time for the original comparison.

We still wanted to use a material that had good hardness, thus our choice to use the Cobalt Chromium (CoCr) material. The CoCr material is a very good alloy for direct part creation, but is not recommended for tooling inserts. The time to build the first inserts using CoCr was significantly longer than had we used the MaragingSteel MS1 material (the MS1 material scans roughly twice as fast as the CoCr material) plus the ‘as built’ MS1 inserts are much easier to post-machine than CoCr is.

Another factor that added extra time to our first comparison was the additional work required as a result of the CoCr inserts warping. MS1, on the other hand, is a material not prone to any heat-induced warping—thus the tolerances coming out of the DMLS machine typically are tighter than what we see in CoCr inserts. The combination of stable dimensional accuracies with the ability to take MS1 inserts up to a 50-54 Rockwell C hardness indicates that these inserts can be considered for production applications and not just for prototyping.

Second Round Results

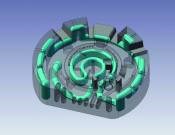

With the above items in mind, Extreme Tool and Morris Technologies designers went about the task of redesigning the inserts to be more DMLS friendly, in the process eliminating a significant amount of volume from each the core and cavity blocks. This is aptly illustrated in the Figure 1.

The redesign of the inserts (Figure 1) in combination with the material change to MaragingSteel MS1 allowed for a reduction in build time of roughly 160 hours (see Photo 1). Above all other factors, this was the most significant contributing item to the success of our second attempt and clearly illustrates the importance of designing to the process and using the appropriate alloy when making tooling inserts via the DMLS process.

Downstream of the build, other timesavings were realized in the post-machining steps due to less warping of the inserts and closer tolerances achieved out of the machine. In total, roughly (56) hours less time was spent post-DMLS build compared to the original time spent on the first inserts (106 hours)—a 53 percent reduction in post-insert machining time.

Chart 1 shows that tremendous progress was made on the second round of producing inserts via DMLS over the first round.

Instead of showing almost twice the cost and 40 percent more leadtime to create the inserts that we saw in the first round compared to the traditional route, the second round now shows the DMLS MS1 inserts to be roughly 7 percent less cost and 25 percent less time to produce.

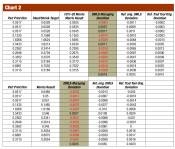

Although the traditionally manufactured inserts still show a slight advantage in holding tighter tolerances, this second round of DMLS inserts witnessed an ability to hold much tighter tolerances than the CoCr inserts and they compare favorably to conventionally machined/EDM inserts (see Chart 2).

Although traditional methodologies will still be twice as accurate on average as DMLS produced inserts, for applications where tolerances can fall in the +/-0.002” range DMLS may be a solid fit. Where the tolerances need to be held tighter, creating DMLS inserts as near net shape and post-machining may be another cost-effective way to reduce time and cost.

Summary

In the first comparison that we ran using DMLS versus conventional toolmaking technologies, we saw DMLS falling short in all categories that we were tracking—including cost, leadtime and quality. However, many lessons were learned that were applied to the subsequent round of comparisons and using designs more focused for the DMLS process and the appropriate alloy for making inserts, we have demonstrated that DMLS is a technology that can help reduce costs and leadtimes while still producing accurate parts. When adding the advantages that conformal cooling lines have over conventional toolmaking technologies, DMLS becomes both a viable and potentially a very powerful technology to consider for those projects that fit well with the process.

Related Content

3D Printing Innovates Hot Runner Manifold Design

Metal 3D printing combined with a conventionally machined manifold block overcomes flow shadows on valve gates and offers faster color changes while providing closer system pitch centerlines between cavities.

Read MoreProducts and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreHow to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read More3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

Read MoreRead Next

Direct Metal Laser Sintering and Tooling

The applications, benefits and limitations of direct metal laser sintering for mold manufacture.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)