How to Decrease Your Internal Mold Maintenance Costs, Part 2

A look at the ultrasonic cleaning process in detail, discussing cleaning detergents, process layout and return on investment.

Last month we introduced the ultrasonic cleaning process as a cost-saving alternative to the labor intensive, manual hand cleaning that is typical in many toolrooms today. This month we will review the process in more detail, discussing ultrasonic tank construction, cleaning detergents and system process layout.

Tank Construction

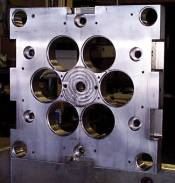

Ultrasonic tank construction is important in that it must be able to support the weight of the load, be compatible with the cleaning chemistry and be able to withstand ultrasonic cavitation over time. For this reason, ultrasonic tanks are usually constructed of 304 or 316 stainless steel with the gauge thickness being able to support the overall size and volume of the tank.

Smaller, all-in-one, tabletop-type units are usually light gauge, seamless drop-formed stainless steel pans. Because these tanks are very thin, they can have only so much ultrasonic power and can support little weight. For tooling applications—even those where smaller tanks are required—a heavier gauge formed and welded tank is recommended, which can support higher ultrasonic power levels, high operating temperatures and heavier loads.

Proper welding is critical in that any voids will be exposed to the cavitation process and over time they can leak in a properly powered tank. It is possible to have a tank that will hold water with no problem—turn the ultrasonics on and the tank will start leaking like a sieve.

The quality of a manufacturer’s tank fabrication should not be taken lightly for this heavy-duty application, and the warranty offered on the tank construction is a reflection of the quality offered by the manufacturer. What good is a 10-year transducer warranty if the tank is guaranteed only for one year?

2. Tank Size and Ultrasonic Power

Determining the tank size for your tool cleaning application is related to size of the tooling at hand as well as the ultimate cost justification of the application. The larger the tank, the more ultrasonic power is required, and therefore the cost. However, contrary to what one would think, the ultrasonic power required to charge a certain volume (watt density) actually decreases as the tank gets larger. Therefore, a 50-gallon tank does not cost 5X the amount of a 10 gallon tank.

It probably doesn’t make economic sense to size a system to handle the largest mold if that mold is a small percentage of the typical tools and if it is significantly larger than most. But, sizing a tank too small can limit the ability of the system to provide maximum cost savings. Too often the customers only complaint is “I wish it were bigger”.

3. Cleaning Solutions and Rust Inhibitors

One of the big advantages of using an ultrasonic cleaning system is that it uses environmentally and user-friendly biodegradeable detergents—eliminating the spray-can solvents that are atomized into the air around the user as they evaporate.

Detergents are a blend of various components such as surfactants, builders, chelates, etc. to lower the surface tension of the solution and allow the microscopic cavitation bubbles to loosen and remove the various contaminants (outgassing residues, oils, greases, etc.).

Depending on the chemical make-up, detergents can range from neutral pH (7 on a scale of 0-14), alkaline (above 7) or acidic (below 7). In general, neutral pH cleaners are effective on lighter soils, such as general shop particulate, light oils, etc. For removal of tougher soils—such as heavy cutting oils, waxes, and plastic outgassing residues—alkaline detergent formulations are the better choice. Acidic detergent formulations work best on oxides, such as heavy rust and stains, and heavy calcium build-up in water lines.

The majority of mold maintenance applications dictates the use of an alkaline detergent. These range from very mild to aggressive—depending on the type of chemistry involved and the concentration of the detergent in the tank. By implementing the detergent with ultrasonic cavitation, the required concentration for effective results is greatly reduced; therefore even aggressive detergents are still user-friendly as they are used at low concentrations.

Care should be taken with alkaline detergents on aluminum tooling. There are specific alkaline solutions that are designed for and safe to use on aluminum, but the majority will start to oxidize and eat the aluminum instantaneously.

4. System Process Layout

Because ultrasonic cleaning uses a nonvolatile, water-based cleaning solution, the components being cleaned need to be rinsed and dried following cleaning. In addition, the ultrasonic cleaning process will remove all residues and will leave a raw metal surface starving for oxidation. Therefore, if the mold components are tool steel (H13, S7, A2, etc…) or 400 series stainless (which still contains enough iron to rust), the components need to be protected with a corrosion inhibitor (rust preventative).

There are a variety of ways to accomplish the clean/rinse/dry/rust inhibit process. The components could be cleaned in an ultrasonic tank, rinsed under a sink or in a bucket of water, blown off with compressed air and then sprayed with a rust inhibitor. However, by having a heated rinse tank, the tooling will keep much of the heat it received from the ultrasonic cleaner and flash dry much quicker—with any residual moisture being blown off with compressed air.

To apply the rust preventative, water-based rust inhibitor can be directly added to the heated rinse tank. As the parts flash dry, the inhibitor will be left on mold components providing long-term corrosion protection.

A very basic system might consist of a heated ultrasonic cleaning tank with filtration system (for removal of particulate from the bath, extending solution life) and a matching heated rinse tank that incorporates rust inhibitor to protect the tools from rusting.

For those systems that will see a lot of throughput, an additional heated pre-rinse tank in front of the rust inhibit rinse tank allows for the majority of detergent and residual contamination to be removed prior to entering the final rust inhibit rinse. This assures cleaner tools by eliminating detergent drag-out from building up in the rust-inhibit rinse stage and being redeposited on the tools.

5. Justification and Budget

“You want to spend how much on equipment to clean tools?!?!” Let’s face it, cleaning gets no respect. And to those that don’t understand the importance of it and/or care about it, it’s the last thing on their mind and the last thing they want to spend money on. Ultrasonic cleaning systems don’t make money. True, but they sure can save it. With a little work and experimenting, it is easy to prove.

The correct ultrasonic cleaning process has both tangible and intangible (at least prior to installation) benefits. The tangible benefits are relatively easy to prove: cost savings on labor and cost savings on cleaning materials (solvent tanks, solvent and their associated maintenance charges, solvent spray cans, abrasives, wipes, etc.).

The intangible benefits are more difficult to prove, but equally (if not more) important:

- Reduce/eliminate mold repair and replacement cost due to surface wear and damage from manual cleaning

- Reduced scrap

- Longer running cycles with cleaner tools

- Improved heat transfer with cleaner water lines

- Reduction/elimination of employee-related health problems—such as upper respiratory issues due to solvent exposure and carpal tunnel syndrome from manual scrubbing

- Reduce/eliminate employee exposure to suspected carcinogens

Fortunately, the tangible benefits alone are, in most cases, justification for the cost of a quality ultrasonic cleaning system. The intangibles are an added bonus.

The cost of a quality ultrasonic cleaning system can range from $5,000 for a small benchtop tank to $150,000+ for a large multi-tank system capable of handling large mold plates tooling. Using some round numbers, let’s look at Chart 1 with a toolroom that has four employees. In this conservative example, the estimated yearly savings in labor and consumables is approximately $84,000.00 or $7,000.00 per month. Again, this is assuming there are no other benefits—such as extended tool life and improved molding efficiency. With a one-year payback for capital equipment being typical, this company could easily invest $50,000 in an ultrasonic cleaning system and have it paid for in less than one year.

An alternative way of looking at the payback is an investment in lean manufacturing. Many companies have become so short on labor that implementing and maintaining a high quality preventative maintenance program has become difficult, and they are either backed up with molds in the toolroom and/or not able to perform adequate PM procedures on the tools for long life in (and out of) the press.

In this particular example, if the toolroom was strapped with work, but short on the available labor to perform adequate PMs, an investment in a high quality ultrasonic cleaning process would eliminate having to hire an employee to meet the needs of the PM program.

Summary

In house testing with even a small, industrial strength ultrasonic cleaning system can usually provide the data to determine the estimated labor savings a company may ultimately realize, while also allowing the toolmakers to get familiar with the technology, the cleaning solutions, and what works best for their particular situation/environment. In most cases, it is something they will not want to give up once they get used to the benefits.

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreWhat You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

Read MoreHow to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read MoreRead Next

How to Decrease Your Internal Mold Maintenance Costs, Part 1

With an ultrasonic cleaning system, a mold shop can realize savings in cost, time and labor, as long as they are educated on the technology, the cleaning solutions and what works best for their particular situation/environment.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More