Maintain

Acquiring Maintenance Discipline

Maintenance discipline is just as much a factor of our working environment as it is our individual character that controls an internal drive toward performance excellence.

Read MoreComplex Parts Put a Premium on High-Tech Mold Design

Equipment and component suppliers are developing a range of products for advanced moldmaking needs.

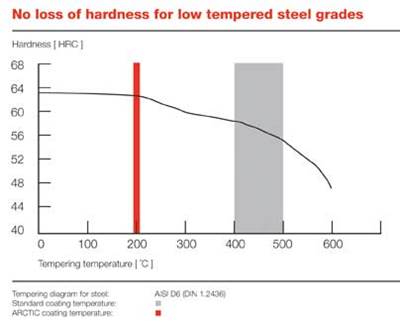

Read MoreLower Deposition Temperature PVD Coatings Allow for Greater Choice in Mold Materials

New technology allows for application temperatures as low as 200°C (390°F) with no loss in coating performance.

Read MoreA Better Reverse Engineering Approach when Modifying Molds

Laser scanning services make good economic sense as they provide precise CAD data available for robot programming, which shortens the actual programming process.

Read MoreHow to Choose the Best Tools For Rework and Repair

Pointers specifically for where hard welds need to be milled.

Read MoreTIG Welding for Mold, Tool and Die Repair

Techniques and intricacies of tool and die welding repair.

Read MoreSelective Materials Strategy Is A Potent Tool for Moldmakers

Reducing mold build costs with different steels and coatings may give North American shops more business from electronics OEMs.

Read MoreArm-Wrestling Unique Measurement Problems

A look at the advantages of a portable coordinate measuring machine in mold design and manufacture.

Read MoreMaintenance Data for Processing Technicians

Data that processors need and what they should collect.

Read MoreLaser Engraving/Marking: A Complement to EDM’ing and Milling

Laser technology may have a place in your mold build process when it comes to engraving and marking.

Read More