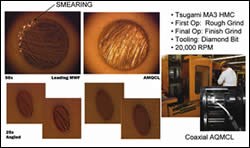

Machining with Advanced CO2 Machining Spray Technology

Advanced CO2 machining spray technology delivers robust, high performance and adaptive cooling and lubrication for challenging mold machining applications.

Carbon dioxide (gas, solid, liquid) as a machining fluid and its beneficial impact on machining operations with regards to both lubricating and cooling qualities has been studied for the past 60 years. One of the earliest documented metal cutting processes using a carbon dioxide spray is described by Thompson Products (later TRW) in the early 1950s.1 The literature contains several good examples of the benefits that can be realized with a CO2-based machining fluid.

With regards to tool wear, a reduction in CBN tool wear has been noted when CO2 gas is admitted to the atmosphere of the cutting zone, removing oxygen and reducing oxidation.2 With regards to tungsten carbide tool wear, it has been observed that liquid CO2 sprayed at base of carbide tool tip retards crater wear.3 In another investigation, it was observed that CO2 gas increases tool life by allowing a larger, protective BUE to form on HSS.4 Gases such as CO2 not only lubricate, but also cool. This point has been illustrated with cooled gases in many applications.5 For example, tool life increases when CO2 gas is cooled to -40° C to -60° C, even when cutting forces rise.6,7,8

Limitations and shortcomings associated with conventional carbon dioxide machining fluid sprays of the past include—among others—a lack of fluid compositional control, limited lubrication ability, lack of temperature and penetration control, and limited machine-tool adaptability. These issues are addressed with a new CO2 machining spray technology called advanced minimum quantity cooling lubrication.

Good Reasons to Change (or at least augment)

The past century has witnessed significant advancements in cutting machines, cutting tools, machine controls, processing materials and coolant-lubricant chemistries. However, surprisingly very little has changed with regards to the application of cooling lubrication. Current cooling lubricant application practices predominantly employ a flooding spray that is as old as the metalworking and machining industry itself. In the past, flooding may have been necessary to compensate for excessive heat generated due to the inferior performance of cutting methods, tools, machines and fluids. Today, more is better is not universally applicable to cutting fluids. In fact, for many operations flooding is wasteful, costly and may even be a detriment to the performance of advanced machining processes, materials and equipment.

The literature suggests that costs related to the use of flooded cooling lubricants can be between 7 and 17 percent of the total costs of the manufactured workpiece. Intangible costs to a business must also be considered. For example, cutting fluids, especially those containing petroleum oils, have become a huge liability. No matter how safe and environmentally-friendly a cutting fluid may be, governmental regulations demand special handling the moment it is poured into a sump.

If the past is an indication of the future, all metalworking fluids will become progressively more controlled and regulated in the years to come. In an increasingly competitive world, this means higher costs and a tougher business climate.

Conventional Coolants and Lubrication

Literally thousands of different cooling lubrication formulations are available on the market for the many different types of machining processes, equipment, cutting tools and materials. Besides machinability issues related to cooling lubricants, selection factors include machine/tool compatibility, sump stability, foaming characteristics, filterability, toxicity, biodegradability, odor, misting, surface wetting, staining, surface cleanliness and disposal issues. Cooling lubrication formulations are tested and selected based on their ability to provide the best mix of all of these characteristics—the tradeoffs being between machining and non-machining performance characteristics.

Alternatives to current practices are getting more serious consideration in response to environmental and operational cost pressures. One attractive alternative is minimum quantity lubrication (MQL). The MQL approach uses a small amount of an oil of one type or another which is entrained as microscopic droplets in an airstream and delivered as a coherent dry (air only), near-dry and wet machining spray. Bio-based lubricating oils derived from soybeans or other vegetable products also are being used successfully with MQL. Natural oils have numerous MQL advantages, including a polar chemistry which reacts more favorably with metal surfaces, unsurpassed lubricity and an abundant U.S. agricultural growing capacity. MQL performance studies in machining processes such as milling, grinding and drilling show great promise; however, issues related to cutting zone penetration, tool adaptation and cooling capacity continue to be barriers to widespread adoption of MQL.

Advanced Minimum Quantity Cooling Lubrication

A new cooling lubrication technology has been developed, called advanced minimum quantity cooling lubrication (AMQCL), which employs simple but powerful physics and engineering princi-ples to provide a superior ability to penetrate, cool, clean and lubricate a cutting zone. It resolves many of the limitations found in conventional and more advanced cooling alternatives such as conventional LN2 and CO2 machining sprays.

The foundation for AMQCL is “hybridization”. The beneficial physicochemical machining actions and benefits provided by MQL, cool gas, solid coolants and various lubricant chemistries are combined in a distinct process. As a result, AMQCL can be implemented alongside many older and newer metalworking machinery, tools and fluids, augmenting a successful conversion to cleaner and leaner machining operations.

AMQCL employs a unique and beneficial combination of technologies:

- Minimum amounts of carbonated coolants and lubricants

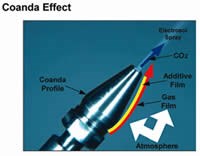

- Coanda effect for additive injection and spray trajectory control

- Precise machining spray temperature control

- Precise cooling lubrication composition control

- Electrostatic charging of cooling lubrication compositions for improved droplet formation and cutting zone deposition

- Pressure and flow control for enhanced penetration, flushing and lubricant deposition

The system combines a source of propellant gas (i.e., compressed air), lubrication additives (i.e., soy oil) and solid and/or gaseous CO2 (i.e., coolant) in various concentrations to form an infinitely adjustable cooling lubricant spray. The system also employs a novel Coanda-coaxial injector and spray applicator.

The applicator employs a passive electrostatic charging mechanism to enhance droplet uniformity, spray force and machined surface deposition. Alterna-tively, an active electrostatic charging system may be employed to provide combination spray charging capability.

The AMQCL system is interfaced both mechanically and electronically with a machining operation. A benefit of a composite CO2 machining spray, and unlike conventional CO2 machining sprays, is that dilute mixtures containing solid coolant particles and subcooled lubricants more easily penetrate microscopic cutting interfaces. Concentrated particle streams tend to “pack” the interface during impact, which prevents the efficient flow of lubricants and coolant particles deep into the cut zone.

Unique Chemistry and Control

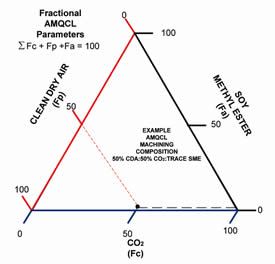

AMQCL spray chemistries combine several chemical and physical cooling and lubrication ingredients and are formed and delivered on-the-fly. The sprays are infinitely adjustable and may include liquids, extreme pressure solid additives and reactive gases that are combined with a propellant gas and injected into a metered flow of charged CO2 gas-solid aerosol. Each ingredient contributes a specific physical and/or chemical dimension—including cooling capacity, penetration power, boundary layer reactivity, lubricity, viscosity, spray particle size and density. AMQCL sprays have variable geometry including adjustable cooling lubricant characteristic from dry to wet composition, room temperature to near-cryogenic temperature, and spray pressures ranging from 10 psi to 150 psi, or much higher, if desired.

Unlike simple atmospheric gases like nitrogen and oxygen, CO2 exhibits very strong hydrocarbon solubility. CO2 gas exhibits >600 percent higher solubility in oils as compared to compressed air. Due to this unique physicochemical properties and cohesion energy, CO2 gas modifies lubricant and coolant additive properties to produce mixtures having lower surface tension and lower viscosity, which aids in penetration into chip/tool capillary interfaces. Moreover, CO2 itself behaves as a reactive boundary layer lubricant—forming carboxylic acid functional groups during tribochemical reactions.

AMQCL technology provides infinitely adjustable cooling-lubricant compositions of CO2 coolant, propellant gases and minimum quantities of any type of lubrication additive(s). Adjustable spray pressure, temperature, coolant particle size and lubricant additive concentration allow a machinist to customize a cooling lubricant composition for any application. One or more individually controllable and flexible Coanda or coaxial spray applicators may be employed to provide optimum cooling, lubricating and cleaning actions.

Managing Heat

Machining heat is generated in three ways:

- The deformation of the material (metal, plastic, ceramic, composite) in the shear zone ahead of the cutting edge.

- The point of separation when the material is physically pulled apart.

- The friction of the chip as it contacts the surface of the tool edge as it is pushed out of the way.

AMQCL helps control machining heat by providing both physical and chemical cooling and lubrication effects. Frictional heat generated at the cutting edge is eliminated through the delivery of reactive lubricants (chemical effect)—including carbon dioxide gas, which produces beneficial tribochemical reactions. The majority of the machining heat produced by the deformation of the material itself is removed using adjustable spray compositions containing microscopic particles of solid carbon dioxide, which impact hot surfaces at high velocity and remove heat through a phase change (physical effect) phenomenon. Using a physicochemical approach, heat generation is controlled and heat is not allowed to accumulate in the tool or workpiece, which would cause temperatures to rise.

Superior Penetration Power

The combination of sublimating solid coolant and subcooled lubricants (mass) with near-sonic air flow (velocity) creates significant penetration power (Force = mass x velocity), which allows the coolant and lubricant particles to penetrate deeply into a cutting zone. Particle velocities of between 50 m/s and 400 m/s are easily obtained with AMQCL. Upon entering the cutting zone, the cooling lubricant spray provides chip cooling and chip evacuation during sublimation or evaporation of the CO2. During expansion, electrostatically charged CO2 gas and lubricant uniformly coat the surfaces, penetrating cutting interfaces, and providing hydrodynamic and boundary layer lubrication. Very high penetration power can be produced using the unique AMQCL spray composition as compared to conventional high pressure flooding techniques. For example, microscopic particle-fluid impact stresses of over 8,000 psi are easily achieved with this technology.

Cutting Performance

In a standardized cutting test performed by an independent laboratory (TechSolve, Inc. in Cincinnati, OH), AMQCL (using a bio-based oil additive) outperformed conventional flood processes, including best-in-class synthetic oils, soluble oil and semi-synthetic with EP—in terms of both uniform tool wear and cutting force.

Moreover, a recent hard turning field demonstration illustrated how the AMQCL process changes the established paradigm in the hard machining. Compared to dry turning, an AMQCL composite spray improved PCD-coated carbide insert life by greater than 10x with 2x deeper cutting, and resulted in a better surface finish. This is a machining process thought to be best performed under “dry” (i.e., no coolant) conditions.

Advantages for Tool, Die and Moldmakers

AMQCL offers multiple technical advantages and opportunities for tool, die and moldmakers. These include, among several others, the following:

- Supercharge existing cutting fluids in minimum amounts with increased coolant power and cutting zone penetration

- Increase machining efficiency for harder and more abrasive materials

- Improve surface finish

- Test new advanced coolant-lubricant additive combinations in minimum quantities on-the-fly without having to change-out coolant sumps

- Optimize challenging machining processes with customized combinations of coolant, lubricant and advanced cutting tool coatings

Another advantage is that it is a very clean and lean technology. A clean and lean machining and metalworking approach is pollution prevention. Pollution prevention consists of any activity or strategy that eliminates or reduces the use of hazardous or toxic substances, conserves water or energy, and eliminates (or reduces) the generation of nonproductive outputs, hazardous wastes, air emissions, wastewater or other pollutants.

Wrap-Up

AMQCL technology can help businesses improve productivity while reducing operating costs and environmental pollution. It achieves this without compromising the selectivity, control and performance that they now enjoy with current metalworking fluid technology. The technology uniquely addresses the shortcomings of the cutting fluid alternatives while capturing all of their inherent benefits. AMQCL is applicable to metalworking and machining operations such as turning, milling, facing, threading, boring, grooving, grinding, dicing, and polishing, and more particularly, to a metalworking and machining operations at higher speeds.

AMQCL can be implemented alongside many older and newer machining and metalworking alternatives—including machinery, materials, methods, processes, cutting tools and fluids—augmenting a successful conversion to a clean and lean metalworking operation. Finally, for tool, die and moldmakers, AMQCL technology enables the use of advanced manufacturing materials, tools and machining techniques while providing clean and lean manufacturing benefits.

1 U.S. Patent No. 2,635,399, West, April 21, 1953.

2 V.N. Ponduraev, Russian Eng. J., 59 (3), 1979, pp. 42-44 Study of Cubic Boron Nitride (CBN) Tools.

3 W.S. Hollis, Int. J. Mach. Tool Des. Res., 1, 1961, pp. 59-78 Study of Carbide Tool.

4 N.N. Zorev and N.I. Tashlitsky, Machinability, ISI Spec., Rep. 94, Iron Steel Institute, London, 1967, pp. 31-34.

5 Tribology in Metalworking, Friction, Lubrication and Wear, John Schey, American Society for Metals, 1983, pp. 624-625.

6 I. Ham, K. Hitomi and G.L. Thuering, Trans. ASME, 83, 1961, pp. 142-154.

7 L.Walter, Can. Mach. Metalwork., 76(8), 1965, pp. 94-97.

8 F.A. Monahan et al, Am. Mach., 104 (May 16), 1960, pp. 109-124.

Related Content

The Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreDesign Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

Read MoreFive-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.

Read MoreRead Next

High-Speed Machines Deliver Speed, Accuracy, Repeatability and Finish

The addition of high-speed machines that blend a reasonable cost with high performance helps one moldmaker realize a huge competitive advantage.

Read MoreWaterjet Cutting and Where It Fits in the Mold Build Process

Waterjet features and applications mold manufacturers should consider.

Read More

.jpg;maxWidth=300;quality=90)