Machining

Considerations for a High-Feed Milling Strategy

High-feed milling is becoming the chosen methodology for removing as much material as possible in the shortest amount of time, as more shops equip themselves with high-speed CNC machining capability and sophisticated CAM programs.

Read MoreTop 10 Machine Vision Improvement Opportunities

As the global manufacturing market continues to get more competitive, it is important to ensure that automation processes are running at peak efficiency levels. Any process-related malfunction is considered downtime, and directly impacts company profitability. Machine vision is an area that, when set up correctly, can reduce process inefficiencies.

Read MoreHow to Choose the Right CNC Router

With moldmaking the focus is on injection molding or other mold types that use wire EDM or CNC machining centers to create the mold components. Your typical machining center weighs several tons and has a relatively small working envelope compared to a CNC router. The mill’s massive construction lends itself to machining rigid materials with very tight tolerances. While this type of CNC is suited for injection molding components, it isn’t always the ideal tool for the job when we broaden our scope of moldmaking and the current opportunities in the marketplace

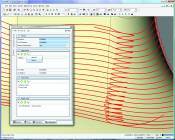

Read MoreSimplified Approach to Complex Five-Axis Machining

As multi-axis machine tools become more complex, CAM software systems must provide a more elegant way to program them.

Read MoreFeature-Based CNC Programming Cuts Programming Time by 25 to 75 Percent

Moldmaker switches to new programming software that auto-matically recognizes features and allows the programmer to define a process for the feature that can be repeated each time a similar feature is encountered; and, allows for more timesavings via its improved rest machining and trochoidal milling capabilities.

Read MoreMicro Tooling for a Growing Micro Moldmaking Market

Without proper tooling, one cannot imagine the challenges of entering a world of micro machining where the tooling used is sometimes also very challenging to see.

Read MoreImprove Process Economics For Roughing Mold Cavities in Hardened Stock

Mold manufacturer improves cavity hogging and debottlenecks key operation on popular hardened stock with a facemill featuring three flutes with 6-sided inserts.

Read MoreMeasure Your Success for Rough Milling Improvements

In moldmaking, most applications still follow the traditional two- or three-phase process consisting of rough/pre-finish/finish, in order to hold tolerances. The following article will focus on the first phase of operations—the roughing phase—and how shops can improve rough milling applications with new strategies and cutting tools.

Read MoreThe Benefits of a 4+1 Machining Process

The benefits of 4+1 machining can better the results of 5-axis machining: overall cutter life, cutting time and surface finish are improved.

Read MoreHigh-Speed Mill Keeps Tight Tolerances, Increases Efficiencies

Busy moldmaker turns to HSM to boost productivity and remain competitive in both the domestic and foreign arenas—and realizes time savings of up to 60 percent.

Read More