Machining

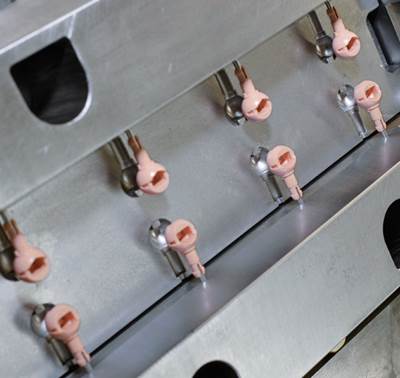

From the Field: Programming Software for Producing Playmobile Toy Molds

If it is still the norm in many tool- and moldmaking businesses to carry out programming either offline or directly on the machine, then the Playmobil example shows that a combination of both provides a lot of scope for creating and implementing new ideas.

Read MoreMachine Tool Expandability Through Efficient Retrofitting

Considerations for determining if retrofitting is the appropriate and economical solution for your shop.

Read MoreHydraulic Fluid Reduces Energy Consumption by Eight Percent

An energy-efficient hydraulic fluid has been developed for use with CNC machines that features low-deposit forming tendencies, provides equipment protection and can extend oil maintenance intervals.

Read MoreElite Mold & Engineering: Team Elite

Being both a moldmaker and a molder allows Elite Mold to be a one-stop team for its customers and the MoldMaking Technology 2009 Leadtime Leader Honorable Mention Award: Small Shop.

Read MoreThe Right PC CNC Brings Speed to Moldmakers

What to look for in a control to get the speed, accuracy, surface finish, flexibility, convenience and value a moldmaker needs.

Read MoreHigh-Speed Machining Simplified

How high-speed machining can be reliably achieved by using the principles applied along with the correct tooling, feeds and speeds.

Read MoreMaking the Most of High-Speed Machining

High-speed machining can cut mold manufacturing time in half, but only if it’s executed with an eye to the special needs of the tools and the process.

Read MoreMetalworking Skills Are in Demand Among Green Power Suppliers

Mold shops seeking new business have sizeable opportunities machining parts for new energy systems.

Read MoreReducing Fixturing Costs with Magnets

A look at magnetic workholding solutions, applications and benefits.

Read More

.jpg;maxWidth=970;quality=90)