Using High-Feed Machining Strategies to Get to Net Shape

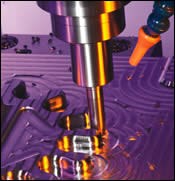

High-feed tooling and high-feed machining could be the key factor in maximizing your shop’s roughing efficiency.

The most important issue facing the mold and die industry in recent years is throughput. Throughput is the amount of work a shop can complete in a set amount of time. This idea of productivity has been under constant review with the pressure from overseas competition.

To survive in the global market with shrinking leadtimes, manufacturers are forced to embrace new time-saving technology. Recently, that technology has been high-feed tooling. Grinding technology has transformed high-feed tooling from large insertable tools to a range of sizes and styles. This new tooling selection has proven to be an irreplaceable solution in many applications and effective for all industries involving machining.

In this article, high-feed tooling will be defined and proven with some common examples. By using a high-feed machining strategy, this technology can be used on any machine tool. Keeping throughput in mind, high-feed tooling and a high-feed machining strategy can be the key to maximizing shops’ machining efforts.

High-Feed Geometry

With new five- and six-axis CNC grinding technology, cutting tool manufacturers have been able to create almost any geometry. With this increase in grinding technology, high-feed tooling has been reborn. The definition of high-feed geometry is producing a positive cutting edge out of a series of continuous radii with no tangent point to induce wear. The geometry must allow the chip to flow up and out of the cut quickly and smoothly. This cutting motion allows the use of heavy chip loads to achieve very high feedrates.

High-Feed Tooling

In the past, high-feed tooling was only available as an insertable tool in larger diameters. As stated above, grinding technology has reinvented high-feed tooling. High-feed tooling is now available in a two-flute insert in sizes 3/8" (10 mm) to 1" (20 mm) or as four flute solid carbide in sizes 1/8" (3mm) to ½" (12 mm). With this overlap of technology, many smaller roughing applications can be streamlined. Machining times in some applications have been reduced by up to 70 percent. This reduction in machine time is due to the high-feed geometry. By allowing heavy chip loads on small diameter tools, high feedrates can be achieved in smaller machining applications. High-feed tooling is proving to be an irreplaceable solution in most roughing applications.

High-Feed Machining Strategy

High-feed geometry is the future of high-speed roughing. In the past, roughing operations have been evaluated only on their metal removal rate. This evaluation usually puts into process the machining strategy of using the biggest tool possible and working down sizes. However, by properly using high-feed tooling, users can achieve the same—if not better—metal removal rate with a much smaller tool.

A high-feed machining strategy should be based on eliminating re-roughing operations and getting to allowable corner radii or net shape faster. To illustrate the different strategies when roughing, a multiple cavity job example has been chosen. The same core geometry was roughed using a conventional roughing approach on one cavity and a high-feed roughing approach on the other.

Testing Conditions:

Material: SKD-300

Material Size: 12.5" x 13" x 3.375"

Target Corner Radii: 0.270"

Machine tool: Makino V-77

Programming Software: Cimatron

Tooling: Millstar

Example 1

This used a traditional roughing process when starting from a solid block of steel. This approach will usually begin by using a large insertable tool and executing re-roughing operations to achieve the target corner radii. This example will use average cutting parameters per the tool and material.

Example 1, Roughing operation 1

Tool Diameter: 1" insertable

Corner Radii: 6mm (12mm round insert)

Number of Flutes: 2 flutes

Depth-of-Cut: .020"

Width-of-Cut: .600" (60 percent of the tool diameter)

Spindle Speed: 4500 rpm

Feedrate: 120 ipm

Total Machining Time: 5:23:21

It is common in cavity and core work to have a target corner radius or net shape to proceed with semi-finish or finishing operations. To achieve this net shape, a series of re-roughing operations are needed with smaller diameter tools. The target corner radii for this example is 0.270; therefore, this example will need a re-roughing operation with a ½" diameter tool.

Example 1, Roughing operation 2

Tool Diameter: 1/2" back draft insertable

Corner Radii: .060"

Number of Flutes: 2 flutes

Depth-of-Cut: .015"

Width-of-Cut: .250" (50 percent of the tool diameter)

Spindle Speed: 4000 rpm

Feedrate: 85 ipm

Total Machining Time: 1:40:38

The results of Example 1 show that to achieve the desired net shape, it has taken two operations. Combining both machining run times has resulted in an approximate run time of 7 hours and 4 minutes. This is the time it has taken to get the net shape needed to proceed with finishing operations.

Example 2

As mentioned in Example 1, to get to the most important and longest running operations—semi-finishing and finishing—programmers and machinists have to achieve a target corner radius or net shape. In traditional machining approaches, this would begin with the biggest tool possible and then work down sizes. However, with high-feed geometry, smaller diameter tools are able to achieve higher metal removal rates than conventional larger diameter tools. Therefore, programmers and machinists can focus more on net shape when approaching cavity and core work.

In Example 2, keeping in mind the 0.270 target corner radius, a high-feed approach would be starting the roughing operating with a ½" high-feed tool. This approach will eliminate the need for further re-roughing operations and produce the target net shape.

Example 2, Roughing operation 1

Tool Diameter: 1/2" high-feed tool

Corner Radii: .052" programmable radii

Number of Flutes: 4 flutes

Depth-of-Cut: .020"

Width-of-Cut: .600" (60 percent of the tool diameter)

Spindle Speed: 5000 rpm

Feedrate: 350 ipm

Total Machining Time: 2:01:39

By using high-feed tooling and a different machining approach, the part is at the desired net shape to proceed with finishing operations in approximately two hours. This has reduced machining time by almost 70 percent when compared to Example 1.

In addition to the reduction in machining time, this high-feed approach used fewer tools, less programs and less setup time to achieve the same net shape. This high-feed approach to roughing has more than doubled the machine’s capacity and increased the shop’s throughput.

An additional benefit of using high-feed tooling is the ability to direct the cutting forces toward the spindle. As explained earlier, this direction of force results in minimal tool deflection. This can allow programmers or machinists to rough to closer tolerances. Instead of leaving extra stock for an additional semi-finishing operation, some cavities and cores can be roughed close enough to begin finishing operations. By using high-feed tooling, shops can increase machine capacity by decreasing processes and run times.

Conclusion

With advancement in high-feed tooling sizes, styles and geometries, programmers and machinists can put the speed back in high-speed machining. By embracing this new time-saving technology and machining strategies, manufacturers can remain competitive in today’s global marketplace. High-feed tooling can be the answer to many roughing applications in every industry that involves machining. This quickly achieved net shape geometry can give the programmer or machinist the flexibility to remove re-roughing or even semi-finishing operations.

A high-feed approach can reduce the amount of processes needed to complete the job and boost process efficiency. High-feed tooling and the machining strategy associated could be the key factor in maximizing your shop’s roughing efficiency. This new tooling selection has provided a new solution to all sizes of workpieces. With high-feed tooling and a high-feed machining strategy, programmers and machinists can begin maximizing their machining efforts by decreasing cycle times and increasing throughput.

Note: The author would like to acknowledge BICO Steel Service Centers for donating the P20 material for the test.

![]()

Related Content

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreDevelopments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreRead Next

The Key to Controlling Your Machining Process

Controlling heat is the most important factor in high-speed and hard metal machining.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More