Selecting the Best Toolholding Solution for Your Shop

A look at ER collet systems and a review of the properties to look for when making your toolholding purchase decision.

It is widely known that choosing the proper tool is a necessity for successful machining, but with the levels of precision and accuracy required in today’s market, the selection of the correct toolholder is equally important. Though the market contains many systems varying in holding power, price and flexibility, none qualify for universal application. As a result, when searching for a tooling device that is the ideal solution, many buyers face the common dilemma of “too much” vs. “not enough.”

The first step to finding a toolholder that suits your specific needs is a careful evaluation of the machining environment. Shops dealing with the upper limits of accuracy requirements will most likely focus on hydraulic, shrink-fit and collet systems. Far more common are those that need to hold tolerances in the 0.0005" to 0.001" range. For these manufacturers, the precision, repeatability and versatility of ER collets make them an extremely wise choice.

A Flexible Solution

Effective in a wide variety of applications, ER collet systems are available in two levels of precision—standard and ultra-precision (UP)—with sizes ranging from ER8 to ER50. This broad selection of collets can accurately clamp tool shanks ranging from 0.2 mm (0.0079") to 34.0 mm (1.3386"), making it easier to clamp more tools with fewer collets, lowering inventory and out of pocket costs.

The use of an ER collet system also allows a shop to evolve its toolholding system as its manufacturing needs change. With ER collets, shops can achieve ideal results working with a standard base system and retain the option to upgrade to the ultra-precision toolholder should the need for high-speed machining applications arise.

Selecting the Right ER Collet System

When buying a car that offers the maximum in high-speed performance, you don’t settle for the $10,000, 4-cylinder bargain; you go for the $50,000 muscle car that packs a supercharged 5.4-liter V8. The same applies to toolholders, where, like cars, you often get what you pay for. It is imperative that buyers know what properties to look for when making a purchase decision.

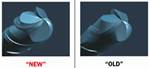

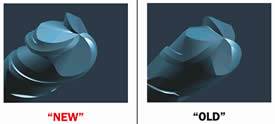

Surface finish, slot geometry and product material are keys to differentiating high-quality ER collets from lesser versions. Well-manufactured systems feature smooth finishes and relief edges that allow the tool to collapse while maintaining strong connectivity. Additionally, they are made from specially formulated materials that aid in maintaining spring, improving durability and increasing collet life.

Low-quality selections often have grainy surface finishes, sharp edges, and inadequately produced material that is prone to wear, tear, and rapid loss of springing and clamping ability. Once a material loses springing, the collet is useless because it lacks the ability to produce consistent clamping forces and run out.

Though visual evaluation is helpful in discerning good systems from bad, it is only the first step in successful evaluation. Flaws in the manufacturing process often result in the production of systems that are superficially sound but unable to withstand the rigors of the machining processes. These defects frequently result in breakdowns and increased costs for mold shops that thought they were getting a good deal.

Though many red flags exist to help buyers avoid flawed products, there are really only two guaranteed proofs of an ER collet’s quality: repeatability and time.

In for the Long Haul

If an amateur mechanic builds an Indy Car and races it at top velocity for 10 laps at the Indianapolis Motor Speedway, it might perform to or even exceed expectations. But this good start is not a valid indicator of the car’s quality and workmanship. Its true value can only be revealed over time, as performance is measured over 50, 100 and 200 laps. At what point will the engine begin to sputter? Will the transmission fail when finally enduring the stress of repeated use? For cars with low quality and craftsmanship, it is anyone’s guess.

Much like the Indy Car scenario, most ER collets will produce similar run-outs and clamping forces for the first 10 or 15 runs, regardless of cost or quality. But over time, the cream will rise to the top, as the best systems continue to maintain clamping strength and limited run-out accuracy. Inferior products, however, will show their true colors, losing spring, gripping force, and accuracy—all of which translate into increased cost of operation. Some shops will simply replace these holders as they wear out. If you are receiving less than 50 clamps per collet, it is time to start evaluating other options.

Protecting Your Investment

Moldmakers must deal with a wide variety of uncontrolled variables, many of which arise during the production process. But the one thing that is within their power is maximizing an ER collet’s value. A well-maintained shop and frequently cleaned pieces will prevent the build-up of rust and debris to ensure positive, consistent results and longer tool life. It also is necessary that the machinist take measures to avoid any deforming of the toolholder by making proper nut torque requirements; pull stud torques; correct tool depth in the collet; and use high quality collet nuts.

Many buyers base their toolmaking decisions on one or two factors, the foremost being price. But those that also consider elements like tool life, quality and manufacturing standards assure themselves of high quality, precise machining at a minimal cost to their shops.

Related Content

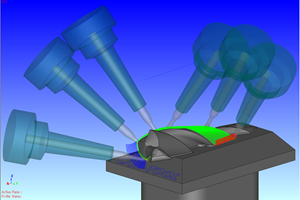

How to Generate the Ideal Tool Path for High-Level Accuracy and Finish

When a mold builder can’t compromise part accuracy and surface finish, CAM software with specialized programming strategies is essential.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreRead Next

Minimal Investment In New Tooling Tech Increases Productivity, Tool Life and the Bottom Line

Having a fundamental base of the facts makes it easier to detail how some of the latest innovations in cutting tool substrates, geometries and coatings can make it easier for one’s moldmaking process to go from fast to furious.

Read MoreHow to Choose the Right Tool Coating for Your Machining Application

Selection criteria and common coating attributes for PVD, CVD and other common coatings.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=970;quality=90)