Enhanced Precision Drives Extreme Transition

A machine that reduces the need for recutting and benchwork laid the foundation for this shop’s shift from mold maker to mold manufacturer.

Setup. Machine. Check. Fit. Done? Not quite. Re-machine. Re-check. Re-fit. Such a sequence was once far more common at Extreme Tool and Engineering. Mike Zacharias, company president, is pleased to report that today, jobs requiring repeat work are more the exception than the rule. That’s because Extreme is no longer in the business of making molds. The company is finding it far more efficient to manufacture them instead.

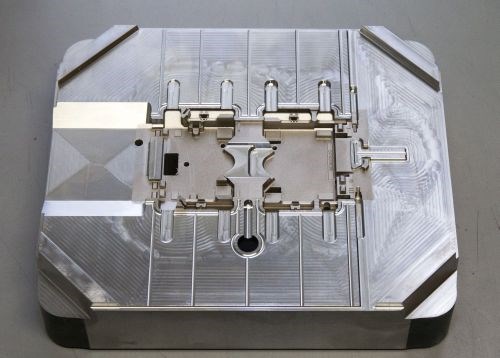

The difference between moldmaking and mold manufacturing is more than just semantic. It’s a different way of thinking. However, executing on this different thinking just isn’t possible without the right technology. That’s why the installation of a high-precision milling machine three years ago was such a turning point for this Wakefield, Michigan, shop. The Yasda YBM 640V3 vertical jig borer was the first machine on the floor with sufficient precision to eliminate downstream benchwork on a regular basis, Zacharias says. The result? Faster delivery, consistent quality, and a happier, more prestigious clientele, among other benefits.

Adapting to the Process

The company’s transition from moldmaker to mold manufacturer wasn’t just desirable, but essential. “We live in an age of instant gratification, and the mold business is no different,” Zacharias says, citing demand for product perfection at warp speed and the lowest possible price.

Efforts to provide just that have brought the shop a long way since getting its start as a six-employee operation in 1998. Today, it offers comprehensive plastic product development services for the packaging, medical, automotive and electronics industries. With a staff of 80 and annual sales approaching $15 million, it operates two different facilities: a 12,500-square-foot mold manufacturing plant and a 17,500-square-foot molding and validation center.

By 2011, however, Zacharias and his team had recognized that something would have to change in order to continue meeting increasingly stringent customer requirements. No longer would the shop rely so heavily on the skill and craftsmanship of its employees to ensure fit and function for every tool. Their expertise would be just as critical, but all activities would be driven by standardized processes—processes worked out well in advance and designed to limit inconsistencies.

However, even the most disciplined adherence to procedure would do nothing to alleviate the variation that naturally arises from manual tasks like fitting and polishing. The only solution for completing the transition from moldmaking to mold manufacturing would be a significant upgrade in the shop’s machining capability, one that would limit the need for excessive benchwork in the first place.

Eliminating Benchwork

Having heard of Yasda, Extreme turned to Jeff Johnson, who at the time owned machine tool supplier All Tech Machinery (currently, he’s die/mold product manager on the Yasda Precision Product Management team at the builder’s U.S. supplier, Methods Machine Tools). Initially skeptical, Extreme took delivery of the YBM 640V3 vertical jig borer after test cuts proved the machine’s capability. “Business changed forever when we put machines on the floor that were more accurate than we were, and we became a process-driven manufacturer,” Zacharias says. “When we ask this machine for a tenth, it gives it to us, and it can easily deliver micron levels.”

The reason such accuracy is so important is that it enables zero-stock machining—that is, milling critical mold surfaces without leaving excess stock. When performed successfully, this strategy significantly limits the need for handwork at the bench. As a result, “The toolmakers no longer need to fight the manufacturing process,” says Trevor Meinke, director of operations/moldmaking at Extreme.

According to the manufacturer, the YBM 640V3 owes its high precision in part to a reinforcement rib under the machine’s bridge that adds rigidity and reduces vibration during acceleration and deceleration. This facilitates the heavy-duty machining often required in mold manufacturing. Meanwhile, the machine’s structure keeps the weight of the spindle head and saddle as low as possible. All critical surfaces are hand-scraped to ensure mechanical accuracy.

In addition to rigid construction, the machine features spindle bearing preload self-adjusting technology, which is designed to ensure optimum preload at the full range of spindle speeds. The spindle itself features rugged construction for long life and efficiency in operations ranging from heavy-duty roughing to delicate finishing. To reduce thermal distortion, the machine features a bridge-cooling system under the X-axis guide. Meanwhile, a jacket cooling system for the X- and Y-axis ballnuts is said to prevent loss of ballscrew pretension. Other features include enhanced chip disposal, and large coolant and lubrication tanks.

Reaping Rewards

The machine’s repeatable precision has proven particularly useful for high-cavitation molds that require full interchangeability, as well as those that require fine surface finishes. One recent example of the latter is a 420SS mold for the mammography market, which often requires true optical-quality finishes on large, contoured surfaces. “It is critical that these molds are machined accurately to a very fine finish, such that limited polishing is required in post machining in order to maintain the accuracy of the surface,” Zacharias says. “We also produce molds for the optometry field where ultra-precise dimensional control is required. In both cases, efficient mold manufacturing could not occur without the degree of precision that this machine provides.”

Another example of work for which the machine is particularly well-suited is thin-walled packaging molds, particularly those subject to high injection pressures with highly contoured parting lines. Extreme Tool recently processed one job involving a six-cavity tool measuring 42 by 36 by 28 inches and designed for a 500-ton press. The job called for hard-milling and polishing blocks of 11- by 13- by 3.5-inch blocks of S7 with hardness ranging from 54 to 56 HRc. The original six-cavity tool also had a full spare stack. Extreme ended up building three more exact copies, all of which had a spare stack, for a total of 28 cavity and 28 core blocks. Migrating this job to the Yasda machine reduced total cutting and polishing time by about 36 percent and doubled surface finish accuracies. “There was almost no re-cut time,” Meinke says. “The molds were within tolerance and went together with very minimal hand work.”

Beyond Precision

The shop estimates that since installation, the machine has provided savings of approximately $300,000 per year. However, benefits extend beyond raw precision and productivity, Zacharias says. For one, he points out that this figure includes savings from extended spindle and cutter life. The machine’s durable construction will continue to pay dividends, he says, noting that he expects the Yasda to last “15 to 20 years, versus the 5 to 10 years of a typical machine.”

The machine has also contributed to new business. Notably, some of that business is coming from a “higher level of clientele that helps separate Extreme from our competition,” says Doug Hippe, director of continuous improvement and training. The shop has also come to expect a higher level of support since Methods came onboard as Yasda’s distributor in 2013, Zacharias says, noting that he sees a “considerable advantage” with the extent of the company’s application engineering, customer service and sales resources. Other benefits are intangible, such as the increased confidence Zacharias says he has seen in operators tasked with running the machine.

Of course, one of the greatest measures of success is customer satisfaction. In 2014, the shop reports that its on-time delivery rating was 100 percent. Its client satisfaction rating was also at an all-time high. “I am confident in saying that there is no way we could perform consistently at these levels without the investment we’ve made in top-end machines,” Zacharias says. “The bottom line is that Yasda played a crucial role in our transition from a traditional moldmaker to the precision mold manufacturer that we are today.”

Related Content

Hybrid Milling/Drilling Machine Reduces Total Mold Machining Time

MSI Mold Builders now squares, plus drills and taps eye-bolt holes on 50% of its tools in a single setup using a five-axis milling/drilling center with a universal spindle.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=970;quality=90)