Flexible High-Speed Mold Machining

Use this planning guide to identify the right double-column machining center to fit your mold machining needs.

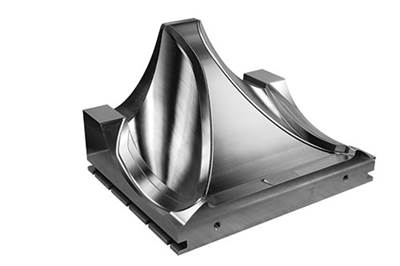

Molds and dies come in all different shapes and sizes, and flexible high-speed machining plays an important role in their manufacture. Double-column machining centers are powerful, efficient machines with a wide range of functionalities that can give you the results you are looking to achieve.

If you’re in the market to purchase a double-column machine, there are several factors to consider before making an investment. Ultimately, you need to decide upon the criteria that currently matters the most to you, while also considering what your manufacturing needs may be down the road. For example, which functionalities are the most important to your large mold machining? Is it multiple attachments, tolerance control, a compact footprint or bed size?

Here are some of the variables that need to be considered when setting up particular specifications for your desired double-column machine:

Vertical machining. Vertical machining is ideal for simple work like cutting holes in large plates. Simplicity is the name of the game, so a double-column vertical machine is ideal if you don’t need five-sided functionality. With this type of system, the spindle is fixed and not easily changed out.

Five-sided machining. Some double-columns can be configured with vertical and horizontal attachments that allow the machine to function as both a vertical and horizontal machine. If your part needs multiple-face machining, this functionality should be an important consideration. Rather than repositioning a part, the operator can machine it in one clamping, which produces a more streamlined approach to mold machining.

Five-axis machining. This functionality allows for full five-axis part contouring. It is also useful for shape profiling and for light–to-medium cutting applications. In addition, five-axis machining allows for shorter setup times and reduced workholding requirements, which generate more complete parts per operation.

Five-axis indexing. For heavy-duty cutting applications, five-axis indexing functionality is essential. It’s rugged and offers more powerful cutting options in one- to five-degree increments, and it is ideal for process-intensive machining such as moldmaking. This type of machining improves accuracy, reduces toolchange time and can yield significant increases in productivity.

Tolerance control. Consider the type of tolerances your parts require, then look for a machine that offers options or enhancements on tolerance. High speed and accuracy are essential for increasing throughput, and with today’s technology, you should not have to choose between the two. You can achieve high speeds without sacrificing quality, and a

throughput advantage will give you a competitive edge in the marketplace.

Enclosures. Double-columns are massive machines, so running them in the safest manner possible should always be a priority. Most people think enclosures are solely used to maintain operator safety, but they also keep the manufacturing area clean and neat. Jobs are contained, as coolant is prevented from spraying and chips from flying. Enclosures are mainly used for containing the bed however, rather than the entire machine.

Bed size. The size of the parts to be machined will determine bed size. As mentioned earlier, be sure to consider your current and future needs, as beds cannot be changed out. Carefully pick a bed large enough to access all sides of the parts that you’re cutting, especially if you will be manufacturing a part that requires multiple-face machining.

Lastly, it may be a smart to consider a double-column machining center that is built specifically for your needs and desired functionalities. An off-the-shelf solution may not be the best fit. Weighing the benefits of the available functionalities will help you decide which machine is best-suited for your moldmaking needs, both today and tomorrow.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read More3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

Read MoreRead Next

Smooth Surfaces without Hand Finishing

Advances in NURBS functionality speed up cycle times, meet high-accuracy finish requirements and allow molds to be completed on the machine.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More