Breaking Barriers Between Vision and Reality

For this OEM, speeding time to market required empowering its captive moldmaking operation with not only new technology, but the culture to use it effectively.

Seescan can’t afford to farm out work.

For evidence of that, look no further than an incident last year that cost the supplier of utility locating and diagnostic equipment an estimated $50,000. The San Diego-area OEM had recently finalized the design of a brand new product and was eager to bring it to market. To finish a critical plastic injection mold, its in-house manufacturing operation needed just one more puzzle piece: ejector blades and the cavities to accommodate them. Sourced to an outside wire EDM operation, this work had been delayed for weeks. Even worse, the contractor showed no sign of prioritizing it. The more time that passed, the greater the hit to the bottom line. Product obsolescence is always just around the corner in Seescan’s world, and even a slightly delayed launch can mean lost market share.

Today, the company no longer has to worry about such scenarios. In the past year alone, it’s added nearly $1 million worth of equipment—including a new wire EDM—to modernize its captive manufacturing operation. With new capabilities, the company no longer has to rely on outside vendors for any aspect of production. Time to market is faster, and product designs are no longer constrained by manufacturing capabilities.

However, technology wasn’t enough by itself. Realizing the captive shop’s full potential also required a significant cultural shift. Barriers to communication and collaboration—both tangible and intangible—had to be broken down. In short, the shop has transitioned from "islands" of production to a process-focused, coordinated approach that leverages everyone’s input to make the best use of human and technology resources alike.

Kirk Joy, mold shop manager, emphasizes that this journey is still ongoing. Nonetheless, significant improvements in throughput and the capability to manufacture more complex molds are already helping the shop keep up with production demand while simultaneously supporting the company’s extensive research and development efforts. "We need to be able to quickly and accurately build prototype molds for unproven products so that our research and engineering teams can test, tweak and re-tweak to get the process or product they need," Joy says. "We can now prototype in days, not weeks."

A Winning Philosophy

Getting there has required a substantial investment. Nonethe-less, Joy says Seescan CEO Mark Olsson, who founded the supplier of equipment for locating and inspecting power lines, pipes and other utilities in 1983, recognizes the need to spend money in order to make money. After all, Olsson decided to bring a seasoned moldmaker (Joy) on board in the midst of the recession, when the company wasn’t technically even hiring.

That’s not to say Seescan was in dire straits. Ray Merewether, chief scientist and a founding member, says the company has been relatively stable even in tough times. "One thing about selling sewer cameras is that people get desperate when toilets quit flushing," he says. Still, he emphasizes that this can’t be enough to explain the company’s exponential growth curve. Seescan has doubled in size approximately every three years. For that, he credits Olsson’s creativity and foresight, noting that nearly 70 percent of the company’s budget goes toward research and development. "Mark recognized early on that the way to succeed is not to ask customers what they want, but to figure out what they need and provide it," he says.

Just as it had in the past, Seescan emerged strong from the latest recession. Since 2009, it’s gone from 97 employees and $15 million in annual revenue to 210 employees and $50 million in annual revenue. Renewed expansion offered potential to continue an ongoing trend toward more specialization and in-house capability company-wide, from dedicating personnel solely to writing scanning equipment software to the hiring of Seescan’s first patent attorney. As the company emerged from the recession, the time was ripe for similar change in the manufacturing operation.

Breaking Technical Barriers

Circa 2010, the 20,000-square-foot manufacturing area had the same three primary functions as it does today. Non-mold work, consisting primarily of prototype parts, was handled mostly on two lathes (a Romi M17 and a Haas SL10). The majority of cavities, cores, inserts and other mold work, cut mostly from aluminum, fell to four three-axis Haas VMCs (two 2003-model VF0s and two 2009-model VM2s). From there, production and prototype molds alike moved across the shop to two 60-ton Allrounder presses from Arburg. A selection of toolroom mills and other manual equipment rounded out the shop’s resources.

Almost immediately, Joy ordered a surface grinder, radius dresser and squaring block (items he calls "staples" of any mold shop). However, the most significant investments occurred far more recently, after the shop had prepared itself (more on that later). Early last year, Seescan negotiated a package deal with Sodick on an HS650L high-speed machining center with a graphite package and an AG40L sinker EDM, both with linear motors. About eight months later—shortly after the ejector-blade fiasco—it installed an AG400L wire EDM from the same builder, as well as K1C EDM drill for creating start holes.

Although these machines often run consistently for weeks, they also spend a lot of time sitting idle—and that’s OK, Joy says. The Haas VMCs are more than capable enough to handle the shop’s "bread and butter" work on any given day, he explains, and that will continue to be the case in the future. The Sodick machines’ real benefit, he explains, is potential. For this captive shop, the opportunity cost of not having a capability in house when needed far exceeds the expense of spindle downtime. The aforementioned problem with farming out ejector blade work is an ideal (if extreme) example.

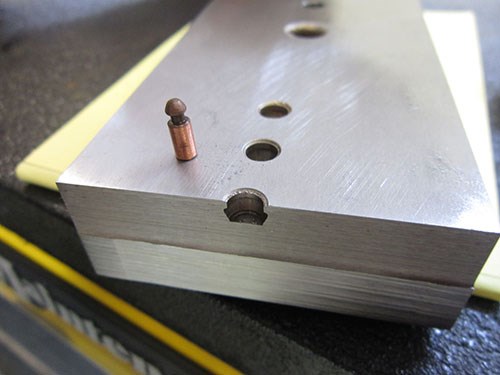

This benefit isn’t limited to work that can’t be performed in any other way. Used to burn the cavity for a product’s handle, the graphite electrode in the picture above features a number of small ribs to increase strength and durability. Previously, features like this would have been machined directly into the aluminum mold cavity on a Haas VMC. However, Joy says such a job could take nearly 90 hours at the machine’s 10,000-rpm maximum spindle speed. In contrast, he says the HS650L and its 40,000-rpm spindle recently churned out three electrodes like the one pictured in a single, unattended night shift, and burning the feature on the AG40L took 6 hours. In addition to improving throughput, this freed the Haas to perform other work while reducing the wear that comes with running so long at full speed.

Just as important as boosting throughput is the ability to design more complex and competitive products while keeping engineering as simple as possible. As an example, Joy cites a waterproof seal that enables submerging cameras to a greater depth. Previously, the shop would have had to either mold the seal in two parts to avoid dealing with a difficult undercut or contract the work out. Instead, it used the sinker EDM to burn a critical feature in an expanding tulip core that enabled releasing the undercut to mold the seal as a single part (see image on opposite page).

Changes weren’t limited to equipment. After all, there’s a reason it took four years to install the Sodick machines. The first order of business was finding fresh talent. The staff has expanded from two to seven, but getting there proved difficult—one position remained open for the better part of three years. Yet, Joy says he did learn one lesson from this frustrating experience: Someone with the right attitude and work ethic is more valuable in the long term than a skilled machinist whose tenure doesn’t last.

Breaking Cultural Barriers

Even as he searched for employees, Joy recognized that making the most of new machining and human resources alike would require a cultural shift. Historically, jobs were assigned on a rotating basis to a single moldmaker who’d handle everything, from plotting CAM tool paths to deciding how to stock the toolchanger to breaking down the setup. This approach often resulted in throughput-limiting scenarios such as machines sitting idle while waiting for a part program, or one staffer casually tending to side duties after completing a job while another struggled with higher-priority work. "The prevailing attitude was ‘This is your job, and this is my job,’" he explains. "We needed to think of it more as ‘This is a job in the shop, and we are all part of the same team.’"

As a physical manifestation of this territorial mindset, machine layout was an ideal place to start. At first, the four Haas VMCs were scattered throughout the shop floor, and each operated essentially as its own island. Now, they face one another in parallel lines, three on one side and two on the other (the shop recently added a fifth machine, a 2013-model VM2). Compared to separate workstations, this layout consolidates floor space and better facilitates the communication required for employees to help one another out when needed. They can also move more easily among the machines, tool crib and office areas.

Rearranging the shop laid the foundation for a new approach to scheduling work. Staffers still take parts from CAD file to completion, but jobs are now assigned at the component level. For instance, if a mold involves 10 different parts, Joy might divide them among three different people, often according to their varied skillsets. Which machines they use and when depends on the shop’s overall production goals, not the needs of any individual—a stark contrast from the "my area/your area" approach of the past. To that end, each VMC’s tool magazine is stocked with identical tools in the same positions whenever possible.

Joy recognized that he couldn’t force this change by dictating from on high. That’s why he says it’s critical to ensure all staffers have a voice in how the shop runs. This approach is perhaps best exemplified by a kiosk on the shop floor that displays the status and priority level of all work in the shop. The ready availability of this information prompts everyone to strategize collaboratively about how best to get the work done (and that’s great for Joy, who readily admits he doesn’t have all the answers). It also limits misplaced resentment because putting work in context of the bigger picture lends meaning to tasks and demands that might otherwise seem arbitrary. "Nobody likes being told what to do," he explains. "The less visible I am, the better."

In that same vein, Joy says it’s also important to let individuals be individuals. For example, he’s OK with letting an employee who’s a rabid soccer fan keep track of scores or even let games play in the background—as long as the work gets done, of course. Any adverse impact of such activity pales in comparison to the potential productivity loss associated with a disgruntled machinist, he claims. "Mark Olsson taught me to manage people for who they are, not who I want them to be," he says.

Remaining Hurdles

The captive shop’s transformation is far from over. For one, not all of the technology that will help move the company forward is yet in place. For instance, at the time of this writing, Joy was zeroing in on a new ERP system to improve tracking of jobs, inventory, maintenance schedules and so forth.

Intangible barriers remain as well. For instance, Seescan’s product designers are still getting acclimated to the new capabilities on the shop floor. To speed that process, they participate in weekly design meetings where Joy and his team provide input on how a mold might be manufactured more efficiently (features that should be burned instead of machined, for example). Likewise, moldmakers benefit from design staff feedback on subjects like gate location and material selection.

As in-house capability and expertise continue to grow, the captive manufacturing operation will be even better placed to adapt fluidly and dynamically to an ever-more varied workload and frequent design changes. "The ongoing evolution of the manufacturing area is allowing the company to take a more aggressive and proactive approach to integrating new technologies, methods and ideas," Joy says. "This, in turn, makes Seescan more competitive by offering products that aren’t available anywhere else."

Related Content

Eden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

Read MoreCross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreMold Maintenance Continues to Matter: Enhanced Training Program in a New Facility

I attended a MoldTrax mold maintenance workshop in 2019 and shared my experiences, and despite changes in ownership, the workshop's remarkable value endures, as discussed in a recent Q&A with the current leadership.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More