Inspection & Measurement

How to Use Thermal Imaging for Mold Approval

Using thermal imaging to look at any part of the process and know the actual hot and cold temperatures and their locations can give moldmakers an edge over the competition.

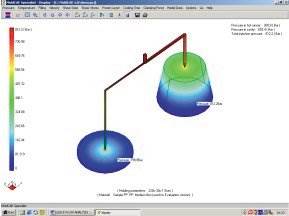

Read MoreQuick Flow Analysis of Hot Runners

Quick flow analysis technology can improve the selection, design and troubleshooting of hot runner tools.

Read MoreTake Measurement to the Tool

A portable CAM measurement system cuts inspection times by 84 percent, improves accuracy and conducts tooling capability studies.

Read MoreBenefiting From Advanced Probing Technology

A progressive moldmaker uses the latest probing technology to attack downtime.Data Import Utility : Edit Content

Read MoreData Analysis Links Design With Manufacturability

New advancements in coordinate measuring machines give moldmakers a new tool in improving operations.

Read MoreBuilt-In Quality

This month MoldMaking Technology magazine asks its readers how to ensure the quality of a mold.

Read MoreMold Refurbishing - Out With the Old and in With the New!

While sending a mold out for repair may cost some time and money up front, in the long run, the shop will benefit from a mold that's "just like new" at a fraction of the cost of a new mold.

Read MoreDimensional Data Collection Through Coordinate Metrology: A Cost-Effective Way to Improve Moldmaking Operations

Advances in data gathering sensor technology and improved measurement and inspection software have made the use of coordinate measuring machines (CMMs) a viable and cost-effective method of improving moldmaking operations.

Read MoreExploring ISO 9000 -Part 14 Corrective and Preventive Action

A Series of International Standards for Quality Management and Quality Assurance

Read More