How to Use Thermal Imaging for Mold Approval

Using thermal imaging to look at any part of the process and know the actual hot and cold temperatures and their locations can give moldmakers an edge over the competition.

Thermal imaging radiates in the infrared spectrum, outside the spectrum of visible light. The wavelength of visible light ranges from 4 x 10-7m on the violet side to 7 x 10-7m on the red side. Just outside the red visible light is the infrared range being about 10-7m to 10-3m. This energy that is within this wavelength is radiant or thermal energy, not visible to the human eye. When you are barbecuing, you can feel the heat from the coals, but you can't see it. This is infrared heat.

Thermal imaging came out of the military and it is used today by the military in heat-seeking missiles, satellites, etc. It also is used in everyday industry for measuring temperatures in steel mills and foundries. Some companies even use it to look at their hot runners for even heat.

Thermal Imaging Cameras

Moldmakers are always searching for better tools to assist them in their daily work, and the new thermal imaging camera does just that. Originally, the equipment costs for thermal imaging cameras were well over $80,000, and they were packed in several suitcases. In addition, it took almost two days to set up the equipment in a production plant. While the results were outstanding, it isn't feasible to carry many instruments today by air, and then ask the customer to give you two or three days' time from a production machine. However, two companies finally have come out with new thermal imaging cameras at an affordable price - approximately $15,000.

The camera weighs approximately four pounds, and uses a power cord or a camcorder battery, which is good for about four hours. Anyone can use the equipment efficiently in about ten minutes after reading the instructions and using the camera to look at a cup of coffee or a glass of water, etc.

The heat is seen through the eye of the camera. Cooler temperatures will appear blue, with the warmer temperatures moving to red, then to yellow and then the hottest temperature will appear white on the camera's infrared picture on the reverse side of the camera. It will show the highest temperature it sees; however, by moving the cursor you can read sixty-four temperatures within the window in which you are focused.

If you desire a photo of the object being viewed, you merely focus the camera, depress the button and the image transfers to the flash card within the camera. Or you can connect directly to a computer and print out the picture of heat you want to save. All of the temperatures within the picture can be brought up from the data.

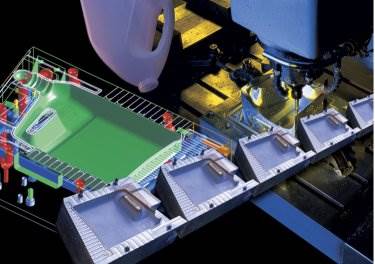

Through the use of thermography you can now look at any part of your process and know the actual hot and cold temperatures and their locations. What better way to check out an injection mold or blow mold and store this knowledge for future mold designs? What better way to go into a customer's production plant and trouble-shoot the process? We all have been in a situation where the mold is questioned or the thermalator or chiller is questioned. You can check your mold cooling or heating sections on your shop floor, as well as in actual use. It can be used as a selling tool, as you can send a photo with the mold to your customers. It also can be used as a training tool for new mold designers to allow them to design the best cooling circuit for a mold design. You can look at your hot runner designs and the manifold and have factual data on the mold, runners, sprues, etc. Everyone is seeking better molds, faster cycles, uniform shrinkage -something to allow your customer to come to you rather than your competitor, whether he is down the street or around the world.

How It Works

In using the thermal imaging camera you have to know the infrared signature of the item or product upon which you are focusing. This infrared signature is known in the industry as emissivity. You have to enter the correct emissivity into the camera's data chip for the item or product you are viewing in the camera's eye.

If you don't know the correct emissivity of the item to be viewed, you can place a piece of masking tape on the object and measure its temperature using the camera. Normal masking tape has an emissivity of 0.95. You can read the temperature of the tape and then move away from the tape and read the temperature. You can then change the emissivity number until the two temperatures match. Once this is completed, record the emissivity setting for the material you viewed and start a database for emissivities and the substrate you wish to view for temperature. There also are charts and graphs published by infrared optical pyrometers to which you can refer and store in the camera.

In looking at various production molds, injection mold temperatures have been found to vary from cavity to cavity by 15'F. In blow molds, hot and cold spots have been noted with over 40'F variations. In looking at hot runner manifolds, more than an 85'F difference has been noted from the center to the outer runners in the manifold. It is no wonder different shrinkages take place in different cavities and large parts have warpage or sink.

The plastic mold industry now has a valuable tool that removes guesswork as to placement and size of cooling/heating channels, heat in the manifold, and residual heat in the molded product, as well as a niche to separate one mold shop from another that uses guesswork or "the way we always did the design." Never before has the plastic industry been under the gun to lower costs and improve the bottom line than it is today and this will continue in the future.

Related Content

MMT Chats: Project Engineer Applies Lean Manufacturing Principles to Growing Sustainability Role

MoldMaking Technology Editorial Director Christina Fuges catches up with MMT’s 30-Under-30 Honoree Katherine Pistorius, who has added Regional Sustainability Coordinator alongside her Project Engineer duties, which demonstrates the many paths one can take in a manufacturing career. Here she shares how this opportunity unfolded for her and what the job entails today and in the future. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreShift in U.S. Mold Imports: Emerging Countries Gain Ground in Market Share

The dynamic nature of the U.S. mold industry's global trade landscape offers challenges and opportunities for growth.

Read MoreVIDEO: What You Need to Know about the R&D Tax Credit Today

A team member from Strike Tax Advisory reviews the tax changes that are impacting the R&D credits for mold builders.

Read MoreRead Next

Century Die: Forging Ahead

Manufacturing blow molds has kept this moldmaker in the black for more than fifty years-and has earned them an Honorable Mention in MoldMaking Technology magazine's Leadtime Leader competition.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)