Hot Runners

High-Performance Hot Runner Systems for Small Precision Parts

Oerlikon HRSflow’s new S Series nozzles offer a compact product with a reduced pitch for the production of increasingly challenging applications.

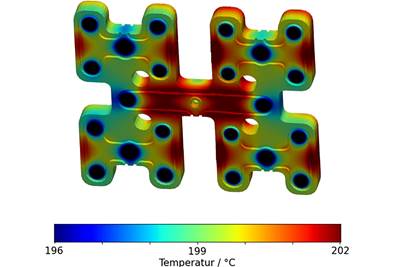

Read MoreThermal Simulation Provides Additional Security for Hot Runners

Hasco Hot Runners will be offering a new simulation tool seeking to maintain a homogenous temperature distribution within hot runner manifolds for high-performance plastics and sensitive additives.

Read MoreArburg and Hasco Partnership Provides Turnkey Solutions

Since the beginning, Arburg has used Hasco as its supplier of standard mold components.

Read MoreReal-Time Monitoring Service Added as Standard Feature to PET and Closure Systems

Husky Injection Molding Systems includes Advantage+Elite as a standard system feature on all PET and Closure systems to accelerate the shift of producing increasingly sustainable packaging.

Read MoreSoftware Update Improves Hot Runner Unit Ease of Operation

The Primezone H1281 now retains a “group and select function” for faster controller parametrization and adjustment of new process conditions, as well as extended external control.

Read MoreExtended Process Window for Non-Cooled Hydraulic Cylinder Supports Temperature-Critical Applications

HRScool Evo, Oerlikon HRSflow’s optimized hydraulic cylinder system, has improved its insulation concept for uniform temperature distribution along the entire hot runner system, without the need for active liquid cooling.

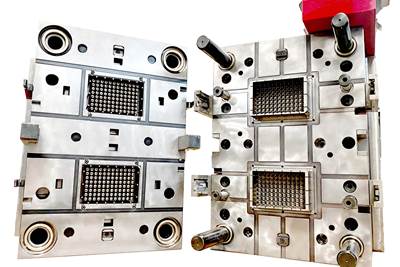

Read MoreHot Runner, Mold Component Partnerships Lead to Innovative Mold Designs

Formula Plastics takes on tooling via sister company Formula Tooling using dedicated partners, 3D modeling services and highly trained engineers to develop advanced mold designs.

Read MoreHot Runner Nozzle Range with Optimized Cable Outlet

The connecting cables on the Hasco Vario Shot have been shifted to the outside of the hot half in the nozzle retainer plate, offering more simplified maintenance, dismantling and reassembly.

Read MoreLight-Blocking Co-Injected Barrier Extends Thin Wall Packaging, PET Preform Shelf Life

Mold-Master’s co-injection multi-layer systems are now available for injection light-blocking barrier materials to reduce light transmittance by up to 99.9%.

Read MoreHot Runner Controller Platform Eliminates Conventional T/C Mold Cables

The TempMaster M3’s TC-Connect technology feature utilizes a new eBOX design that attaches to the mold, reducing cost, weight and clutter.

Read More