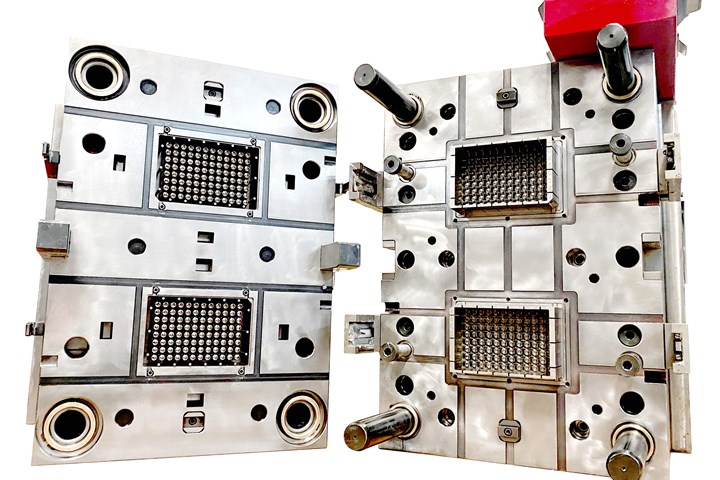

Formula Tooling designs and manufactures high-precision Class 101 medical molds like this one with 192 individual cores. Photo Credit, all images: Formula Tooling

Since 2020, Formula Tooling has built more than 90 molds, growing revenue to over $10 million in 2021. The strategy is simple—build molds that solve technical challenges for strategic customers who appreciate and understand the team’s value to the process.

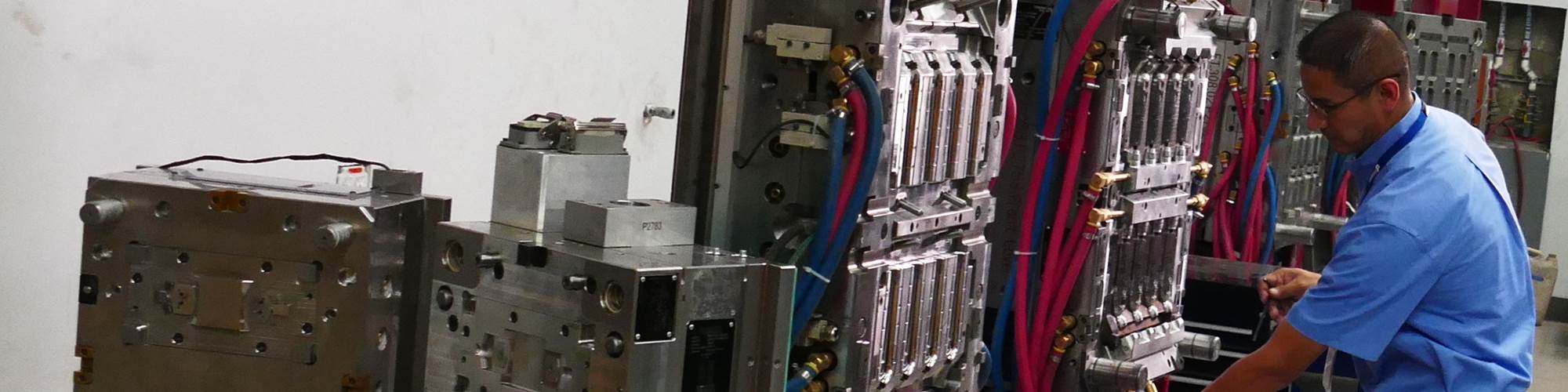

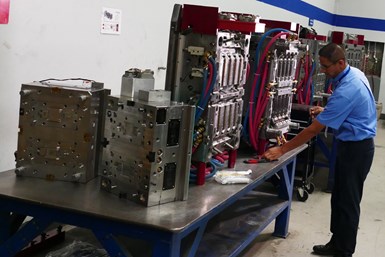

Toolroom Manager Marco Hernandez inspects an eight-cavity mold with 57 slides and lifters.

Many traditional tooling companies focus on the capital to build molds, whereas Formula Tooling says it leverages its supplier partners to deliver the best solution. The Formula Tooling team works this strategy by targeting customers who see the shop as an indispensable partner in mold design, delivery and qualification, as well as investing in the latest tooling technology and design.

California-based Formula Plastics launched Formula Tooling in Mexico to capitalize on new business opportunities involving in-house moldmaking. The company offers a range of services that include feasibility studies, design for manufacturability, MoldFlow analysis, 3D modeling and prototyping, mold manufacturing, startup support and final mold validation. They also provide in-house engineering changes, preventive, corrective and predictive maintenance, as well as repairs.

Formula Tooling’s Managing Director Ruediger W. Kuemmerle joined the company in early 2020 with a resume of building several successful businesses and 16+ years of tooling, molding and product development experience in Germany, China and Mexico.

To develop innovative solutions for customers that improve sustainability, increase production efficiency, improve process repeatability and stretch the boundaries of physics, he brought together an international team of experts—Kunstoff Institut Luedenscheid in Germany, Ewikon Hotrunner Systems, AHP Merkle Hydraulics and CUMSA standard mold parts.

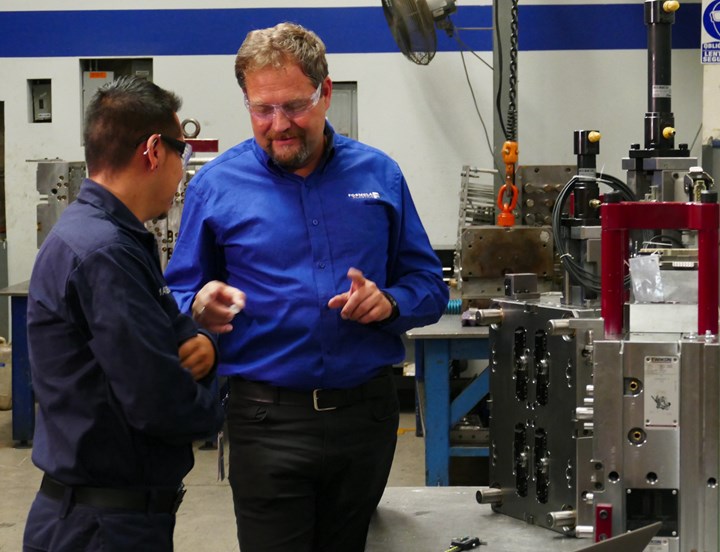

Ruediger trains a young engineer on a two-component medical mold with an integrated index plate.

Partnerships and Problem-Solving

Kuemmerle believes that the key to Formula Tooling’s success is working with dedicated partners, 3D modeling services and highly trained engineers to develop advanced mold standards. Here are three examples of successful partnerships leading to innovative customer solutions:

1. Two-component (2K) nose cap included a metal insert and unscrewing cores. Previously, the team manually inserted the metal insert into the injection molding machine, overmolded it with a hard material, then manually transferred the parts to another injection molding machine, repeating that process for the final overmold with a soft material. As a result, to reach the annual volumes, it required six injection machines.

Formula Tooling fully automated the process for making this two-component metal insert and unscrewing core, reducing the number of injection molding machines from six to one.

Formula Tooling was able to substitute the six injection machines with only one fully automated injection/production cell because of the specific mold design, a high-tech hot runner solution from Ewikon and a 3D-printed end of arm tool (EOAT) from Savage Automation.

2. An electrical plug connector whose existing eight-cavity cold runner mold required removal from the press to change the part version/configuration. There were 12 different pin configurations to manufacture with only one mold. Formula Tooling replaced this mold with a full hot runner four-cavity mold, eliminating the runner, material waste and labor needed for removal.

Using innovative hot runner valve gate technology eliminated runners for these electrical connectors.

This new mold design eliminated the need for a full day to remove the entire mold from the press to change the plug connector version. In addition, a new orientation of the part within the mold now accommodates part changes on the fly with specially designed slides that allow the operator to change the plug part version on the machine in minutes. For this application, two molds (one for male connectors and one for female connectors) now create the 12 different parts with the runner eliminated—reducing cycle time by 32% and version changeover time from six to seven hours, to six to seven minutes.

3. A medical test plate with 384 individual microwells comprised of two different materials. The part requires over 9,000 controlled dimensions. The most challenging aspect was creating a naturally balanced runner for the second material with 384 individual gates that are the size of the palm of your hand.

This two-component life science test plate has 384 individually gated wells and more than 9,000 dimensions.

The existing process used a solid runner plate requiring high injection pressures, longer cycle times and significant balancing issues yielding high scrap rates. Formula Tooling worked closely with Ewikon to develop a hot half containing a manifold with 24 custom-made micro hot nozzles in a 4 x 6 orientation per cavity, totaling 48 tips. This stretched the boundary of physics as the nozzle pitches (the distances between the hot nozzles) were so small that the plate on which they are mounted resembles Swiss cheese.

The Formula team used FEM (finite element calculation and simulation) to determine the required plate thickness to ensure no bending or cracking under the injection pressure and thermal expansion. Kunststoff Institut Luedenscheid did the runner designs and the mold flow simulations with the actual solid melt and not just the part surface grids. The new solution reduced scrap rate to almost zero, required less injection pressure, allowed a smaller machine and resulted in a 100% naturally balanced fill.

It's All About Time and Talent

Kuemmerle also introduced new innovative processes and standards that enable the company to deliver tools in less than half a typical build. To accomplish this, Formula Tooling performs standardized design for manufacturing (DFM) studies and feasibility studies with a 24-hour turnaround time. The same applies to 3D mold designs, as the company has a comprehensive library of standard template designs used as a starting point. As a result, full multi-cavity production molds that might typically take 16-20 weeks in production can now be delivered in only six to eight weeks. In addition, single-cavity pilot tools are made for complete process testing and melt flow analysis for part quality.

Formula’s in-house engineering staff and tooling partners both have teams of high-level engineers and university graduates. This engineering expertise helps develop the company’s advanced mold design standards that solve customer challenges such as eliminating springs within a design, interchangeable cavity and core blocks on high-cavitation molds and a fail-safe system on their valve gated hot runner systems to protect the needles.

For More Information

Formula Tooling / 866-307-1362 info@formulatooling.com / www.formulatooling.com

Related Content

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRead Next

Compact Valve Gate For Small Injection Molding Machines

The Ewikon L2X-Mikro high-performance hot runner system can be integrated into all common mold sizes for injection mold machines.

Read MoreWhat You Need to Know about Medical Processing Hot Runner Systems

Only when there is an understanding of the material properties can you properly select and operate a hot runner system successfully with medical grade resins

Read MoreRobust External Plate Controllers Solve Ejection Problems

Innovative, robust, external synchronized plate controllers solve ejection problems on molds at 3DTech, reducing time, complexity and effort.

Read More