Engineer

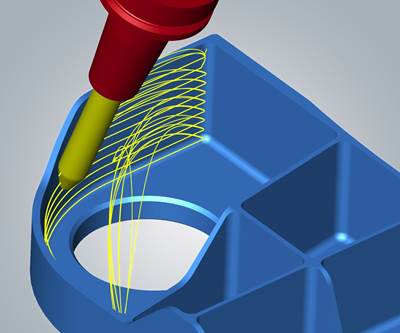

Improving Five-Axis Mold Finishing Operations

In an interview with MMT’s European Correspondent Barbara Schulz, Open Mind’s Peter Brambs explains how its five-axis tangent plane machining strategy can achieve time savings of up to 90 percent.

Read MoreThrowback Thursday: Reusing CAD Data

This Throwback Thursday blog is focused on CAD data and how designers can better work with customers’ CAD designs without “reinventing the wheel,” so to speak.

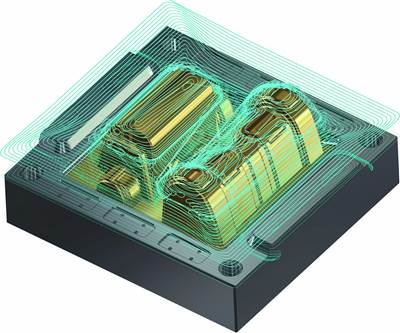

Read MoreLeveraging CAD/CAM Advances

Often-overlooked software tools can enhance moldmaking business competitiveness.

WatchCutting Tool Data When You Need It

From the tool crib to enterprise resource planning systems, tool lifecycle management breaks down expensive data silos.

Read MoreThree Unexpected Machine Monitoring Benefits

If you aren’t monitoring your machines to boost productivity, here are some additional reasons why you might want to start.

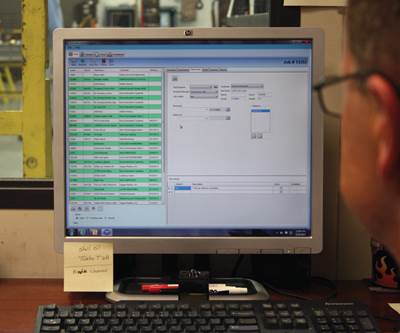

Read MoreEnterprise Resource Planning Software Simplifies Job Tracking

TST Tooling Software Technology LLC, distributor of Vero Software’s Visi products, helped Viking Tool develop an effective job-shop tracking solution.

Read MoreTechnology Showcase: Case Studies for MoldMaking

It’s time for another foray into past case study features that have been published in MoldMaking Technology Magazine.

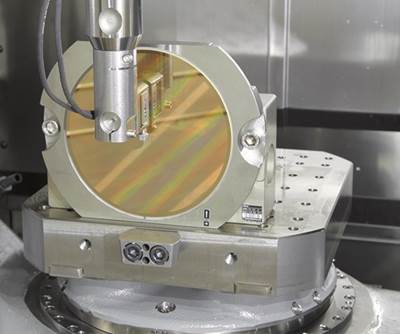

Read MoreCavity Pressure Selection Options and Solutions

According to RJG Consultant and Trainer Shane Vandekerkhof, whether you are a first-time user or a seasoned veteran, cavity pressure selection and placement can at times be a confusing decision. Here is a look at the options available to fit your application to make you successful.

Read MoreTechnology Showcase: Machining, AM and Software

With Amerimold in our rear-view mirror for the time being, there are still several new products that have been released, or will be soon, to bring to MMT readers’ attention.

Read MoreAmerimold 2017: Plastics Exhibitors Promoted Products, Too

Amerimold had it all this year—or should I say it had MORE than ever before. While metalworking tools, materials and systems reigned supreme, the plastics side of the equation was also well represented.

Read More