EDM

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

WatchAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

WatchMaintaining a Competitive Edge: EDM, Automation and Machining Technology Roundup

This month’s technology roundup features products, processes and services relating to EDM, automation and machining. For example, jig grinding for large molds, scheduling automation software, cobot integration, die sinker EDM and much more.

Read MoreMoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

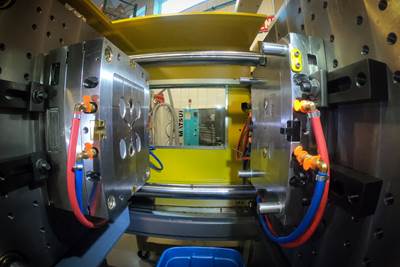

WatchDie-Sinker EDM Series Fits Needs for Enhanced Automation, Speed, Surface Finish

The Sodick ALG EDM series doubles motor response speed for the development of accurate, high-quality molds, and is equipped with automated features for continuous operations.

Read MoreSinker EDM Complements Mold and Die, General Parts Machining Applications

YCM Alliance highlights the exeron 316’s ultra-high precision, large envelope and proven reliability.

Read MoreLarge Mold Shops can Boost Electrode Wear, Cycle Times with Workhorse Sinker EDM

The MC Machinery Gantry Eagle 1400 sinker EDM combines the latest in technological innovation with a human-centric design for utility across industries.

Read MoreRotating Wire Function Cuts EDM Wire Consumption, Optimizes Mold Cutting Conditions

Sodick puts a new spin on its ALN and ALP wire EDM line with a new function that reduce wire consumption by 25% and improve the geometric accuracy and surface quality of workpieces.

Read MoreSmall, Agile Mold Builder Keeps Speed and Accuracy at the Forefront

Michigan-based Zero Tolerance tests the limits of moldmaking and molding with teamwork and technology that permits changes on the fly.

Read More