Design & Mfg. Software

CAM Can Help You Do More with Less

One moldmaker makes significant advances in programming and machining productivity while reducing cutting tool costs.

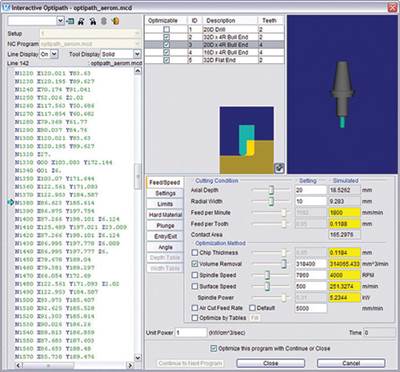

Read MoreChasing the Perfect Feed Rate

Get more than just reduced machining time with NC program feed rate optimization software.

WatchSigns of Growth

If online surveys could capture facial expressions, a recent survey of tool shop executives would probably show a good number of smiling faces, albeit cautiously optimistic ones.

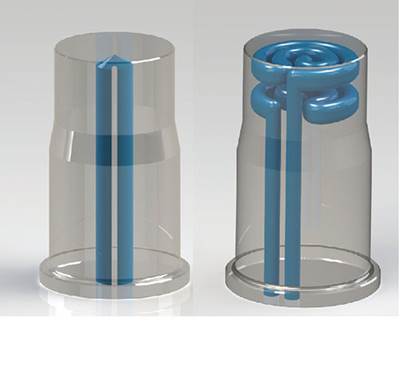

Read MoreMold Cooling Options

A look at three options for integrating conformal cooling into a core or cavity with an emphasis on vacuum brazing.

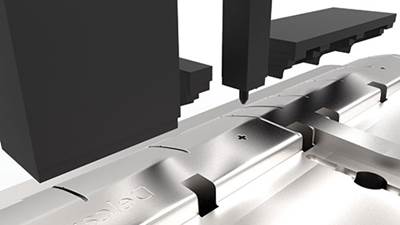

Read MoreIntegrating Electrode Production

How CAD/CAM can help make the design, machining and inspection of electrodes completely integrated.

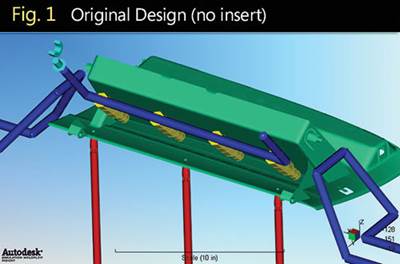

WatchMoving Moldmaking Forward with Dynamic Toolpaths

It's not a matter of how much equipment or manpower you have. What is more important is how well you use what you've got.

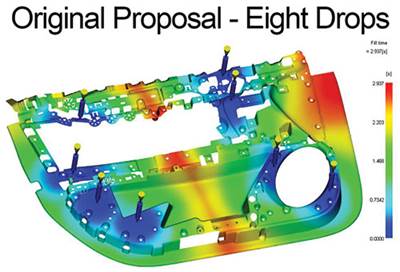

WatchEnhancing Product Quality via Conformal Cooling Design

A look at two cases demonstrating the value of CAE software at the pre-tooling stage.

Read More