Enhancing Product Quality via Conformal Cooling Design

A look at two cases demonstrating the value of CAE software at the pre-tooling stage.

3D printing and RP are not new concepts in the manufacturing world. With more and more price-friendly 3D printers available, self-manufacturing is not a dream anymore. However, for most products, it is still not ready to replace tooling. The concept of RP had been applied on conformal cooling manufacturing for two decades now. Laser sintering is able to manufacture any arbitrary shape of cooling channel to fit the part surface perfectly. This causes shorter cycle time and better product quality.

Problems

There are still other methods that can make conformal cooling channels such as vacuum brazing and CNC machining. Among those methods, laser sintering can achieve the highest design flexibility. However, it is also the most expensive one. There were some problems with the laser sintering method. For example, the mold plate can deflect due to high energy from laser diode. The pipe surface can be too rough, which makes water clog more easily. Others challenges—like sintering dimension and material limitation—have been greatly improved, making laser sintering more applicable to conformal cooling manufacturing.

Product Defects

By changing cooling design more close to the product contour, the temperature distribution is more uniform and heat/cold spots can be eliminated. This can minimize heat-induced product defects such as residual stress, warpage, void, sink mark, etc. Of course, it is also highly related to the product design.

For example, if a product has ribs, it is highly possible to sink at the opposite side of the ribs. If the cooling rate is too fast, voids can occur instead of sink mark. Despite the complexity of product defects for various reasons, conformal cooling can still help to minimize the overall warpage—if properly designed. Here we will examine two common defects—sink marks and warpage—and how conformal cooling can solve them.

Do I Need Conformal Cooling?

Most understand that conformal cooling can always help, it is its cost that oftentimes prohibits its uses. One frequently asked question is: “Do I really need conformal cooling”? It is always the ROI issue.

Generally speaking, two types of products are suitable for conformal cooling: cup/box-like products and large curvature variation products. Another important concern is product thickness. Since plastic is a poor heat conductor, if the part is too thick, the cycle time reduction may not be able to compensate for the cost of sintered part.

Furthermore, how much warp can be improved if conformal cooling is applied? Those answers should be known before mold construction, but how? An efficient way is to use CAE software to estimate. The following two cases indicate the value of CAE and how it can help at the pre-tooling stage.

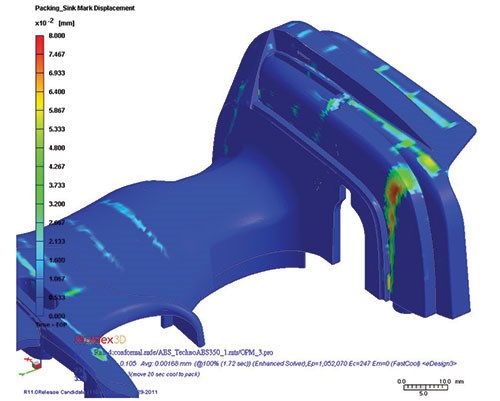

Sink Marks

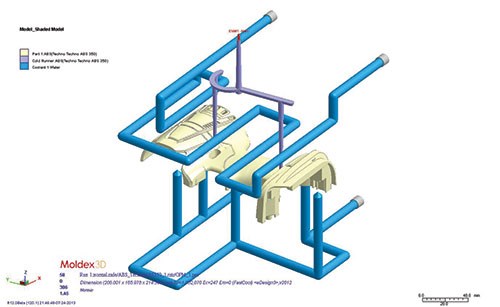

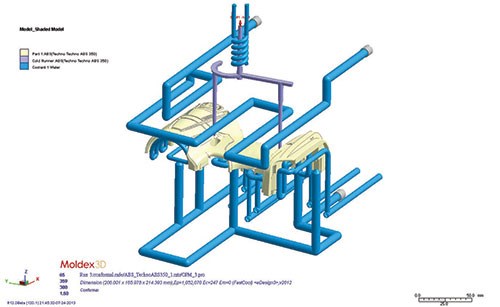

The first case is a drill cover (see Figure 1), the part average thickness is 3mm. The product contour is perfect for using conformal cooling. At the red circle area, sink marks occur (see Figure 2), if cooling time is not sufficient. It takes 30 seconds to avoid sink marks for a baffle design at the core side (see Figure 3). If the conformal cooling channel was applied, it only needs 20 seconds to avoid sink mark (see Figure 4).

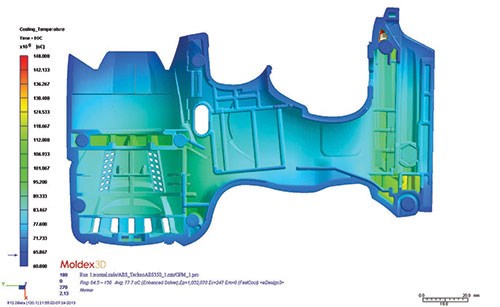

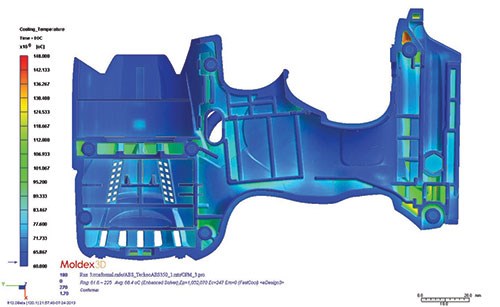

Through simulation, the effect of conformal coolling is obvious. Figure 5 shows the temperature distribution for the baffle (left) and conformal (right) design. The two figures were set at the same temprature range. The core side temperature of the conformal design is much lower than the baffle one since additional conformal channels were applied. The maximum sink mark location (see Figure 6) from simulation results is relatively close to the actual location it appears.

Warpage

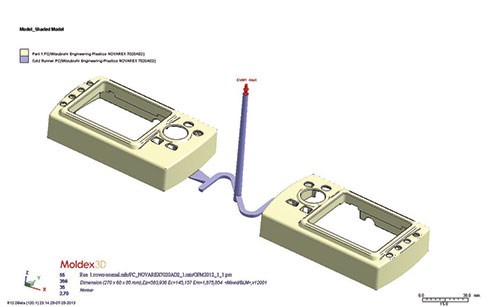

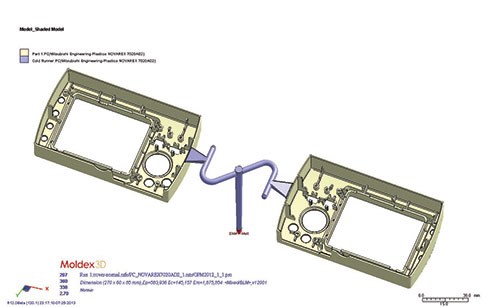

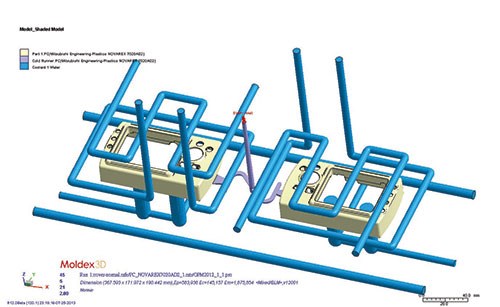

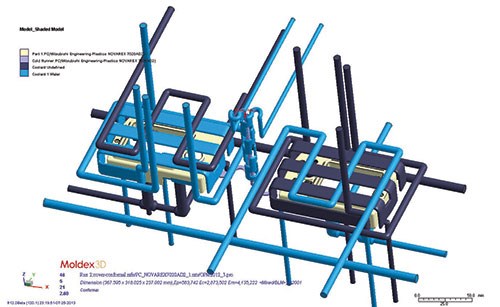

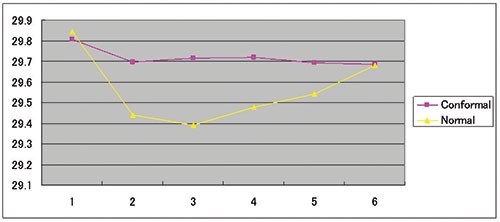

The second case is a digital camera cover (see Figure 7). This product has a severe warpage problem, if only baffles were applied at the core side (see Figure 8). If additional conformal cooling channels were applied (see Figure 9), the warpage can be improved significantly (see Figure 10).

With conformal cooling channels, not only warpage can be improved, cooling time can also be shorten by 30 percent (from 13 seconds to 9 seconds).

Summary

Conformal cooling has two major benefits in injection molding: (1) improving cycle time and (2) improving product quality. Laser sintering is the major manufacturing method for building conformal cooling channels. To best estimate its ROI, the use of scientific tools is necessary. The two real cases demonstrate the effects of conformal cooling channels in reducing sink marks, warpage, and cooling time; and, CAE can effectively estimate these benefits.

Acknowledgement

Special thank for OPM lab, Japan who share these cases and provides detail experiment data which made validation possible.

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreRead Next

Laser Sintering And Conformal Cooling Channels

Moldmakers who are interested in exploring conformal cooling, but are concerned about its complexity and expense need to understand two things: it is neither complex nor expensive.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)