Signs of Growth

If online surveys could capture facial expressions, a recent survey of tool shop executives would probably show a good number of smiling faces, albeit cautiously optimistic ones.

If online surveys could capture facial expressions, a recent survey of tool shop executives would probably show a good number of smiling faces, albeit cautiously optimistic ones.

According to the 370 tooling professionals who participated in a North America tool shop survey1, business is exhibiting clear signs of growth. And while the survey shows that this growth is far from being challenge-free, any tool shop executive will welcome these challenges over the experience of a downturn.

Demand and Competition Growing

One indicator of growing demand is the number of quotes issued by tool shops. Close to half of the survey respondents (49 percent) saw an increase in the number of quotes they issued in the past year, while only 13 percent issued fewer quotes than the previous year.

Tool shops are not only issuing more quotes; many are also getting paid better for their work. Forty-six percent of the respondents believe the price of tooling has increased in the past five years, while 26 percent think prices went down.

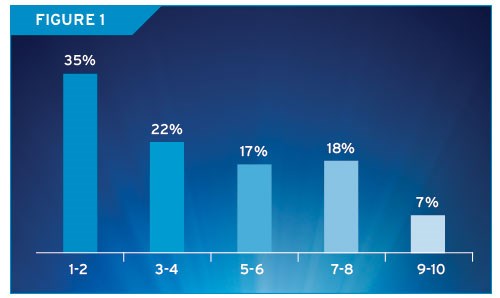

Not surprisingly, the growing demand has spurred tougher competition. Forty-five percent of the respondents say competition today is stronger than it was five years ago, and 35 percent say they win only one to two quotes out of every 10 they provide. Forty-eight percent believe the primary reason for losing to the competition is price (Figure 1).

No. 1 Challenge

With the growing demand comes the industry’s most burning question: Who will do the work? More than half of the tool shops surveyed have increased their number of employees in the past two years, and as many as 31 percent of the shops have increased their workforce by more than 25 percent throughout that period.

Hiring additional qualified employees is the first step survey respondents say they would take in order to make their businesses more successful. Seventy-three percent of the tool shops that participated in the survey expect to hire additional employees in the coming year. Close to a third (29 percent) expect to hire three to six people, and 15 percent plan to hire seven or more new employees in the coming year.

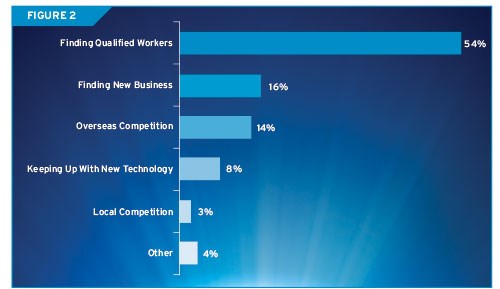

At the same time, it is worth noting that 58 percent of the survey participants have been employed in the tooling industry for more than 20 years, and 26 percent have been in the industry more than 10 years. With few new workers joining the industry, it is no wonder that finding qualified workers is the No. 1 challenge cited by survey respondents (Figure 2).

When it comes to passing the moldmaking torch, decades of a shrinking job pool have driven many away from the manufacturing sector, especially young workers. “There is a bad perception about manufacturing jobs,” says Keith Gerber, owner and president at Hoosier Pattern (Decatur, Indiana). “People think a machine shop means a dirty environment and low pay. It’s quite the opposite. The shops are clean and equipped with the latest technology. Employees are highly trained, highly skilled and well-paid.”

The first step in drawing in young workers is changing this perception. Gerber is doing more than just talk. “I’m trying to set up meetings with the local high schools to bring the counselors and teachers out here so they can see it with their own eyes.”

Hoosier Pattern also has set up an apprenticeship program that brings in high school graduates to teach them the trade. After five years in the program, apprentices have logged 10,000 hours of on-the-job training, while also earning credit hours at a technical school. “Rather than finishing college with huge debt and no occupational skills, our apprentices get a raise every quarter and graduate with no debt and with highly sought-after technical skills,” Gerber says.

Other shops are taking similar steps. Industrial Mold & Machine (Twinsburg, Ohio) is equipping employees with iPad tablets and applying innovative social networking technologies to bridge the gap between generations and speed up knowledge transfer to apprentices.

Vocational institutions and technology vendors also are doing their share in the effort to train new workers. Starting this year, students at the McCann Vocational Regional High School in North Adams, Massachusetts, have the opportunity to gain hands-on experience with CAD/CAM software, thanks to the donation of $900,000 worth of software licenses from Cimatron.

“We are preparing our students to be significant contributors to the manufacturing economy,” says James Brosnan, superintendent of Northern Berkshire Regional School District. “Manufacturing today is all about speed, so training students on software that enables them to be more productive is a real asset to them, to their future employees and to the industry.”

The Path to Productivity

Close to half (44 percent) of the survey participants say their delivery times have gone down over the past two years, while only 22 percent say they have increased. Sixty-two percent of the respondents delivered more than 90 percent of their jobs on time.

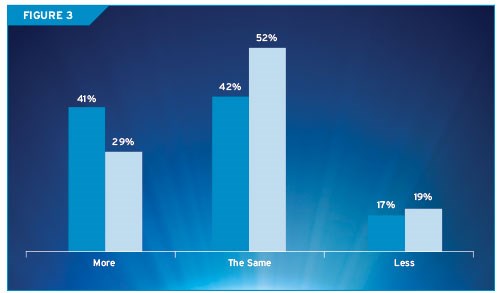

How are shops able to accelerate delivery times while battling the shortage of qualified employees? Continuous investment in new equipment and software makes shops more efficient and productive. Over the past 12 months more than half of the shops surveyed (59 percent) invested in new software and 73 percent invested in new equipment. More than 80 percent of the shops say they intend to invest the same or more in equipment and software during the next 12 months (Figure 3).

Looking Forward

So what does the future hold for tool shops? Tool shop veterans have been around long enough to recognize that the time to invest in the future is now, while the industry is on the upswing. They know that investment in technology will pay off both in times of growth and when business tightens up, and that training the next-generation workforce is a top priority.

1 Conducted by Cimatron.

Related Content

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreRead Next

CAD/CAM’s Role in Customer Collaboration

Seven skills—enhanced by the right CAD/CAM solution—that will help you win more business.

Read MoreSix Best Practices for Mold Design

A few key mold design strategies can go a long way in improving your mold building operations and customer support.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)