Case Study

Workhorse Shrink-Fit Machines Yield Repeatability

Omega Tool Inc. switched to a toolholder/shrink fit system for better quality, improved repeatability and longer cutter life for its ultra-precise mold machining.

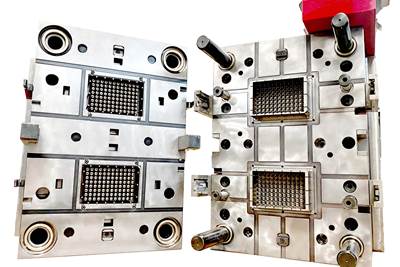

Read MoreCompact Mold Components are Critical to Keep Connector Program Cost-Competitive in North America

Molded Precision Components relied on Heitec compact hot runner, valve gate systems to enable a mold to fit in small press’ limited daylight opening.

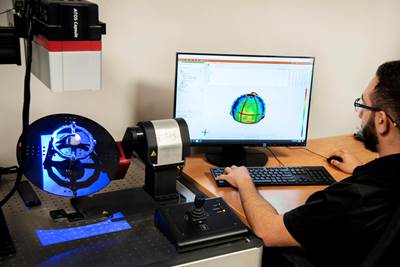

Read MoreHelping High-Precision, Multiaxis CNC Machines Maintain Tight-Tolerance Control

Standardizing Heidenhain control systems on multiaxis CNC machines across the shop floor help Cavalier Tool streamline setups and post-process work, increase accuracy, and improve turnaround and scheduling flexibility to maintain its competitive edge.

Read MoreHot Runner, Mold Component Partnerships Lead to Innovative Mold Designs

Formula Plastics takes on tooling via sister company Formula Tooling using dedicated partners, 3D modeling services and highly trained engineers to develop advanced mold designs.

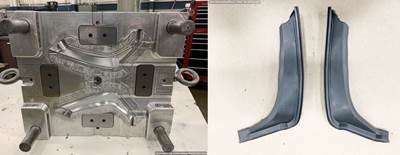

Read MoreVertical Machining Center Designed for Moldmaking Alongside Metal 3D Printers Brings Virus Face Masks to Market Quickly

Speed and accuracy of a new vertical machining center are vital to a two-process approach for quickly producing much-needed face mask molds.

Read MoreWestminster Tool Run Rigorous DOE on New 3D-Printed Tool Steels

Hybrid 3D printing platform offers mold builders high-tolerance metal parts faster, at lower cost and with less secondary finishing.

Read MoreRobust External Plate Controllers Solve Ejection Problems

Innovative, robust, external synchronized plate controllers solve ejection problems on molds at 3DTech, reducing time, complexity and effort.

Read MoreDouble-Column Bridge Machine Increases Blow Moldmaker’s Capabilities

High-speed double-column bridge machining center runs faster and produces better surface finishes, increasing capabilities of blow mold builder M.C. Molds.

Read MoreInnovative Indexable Deep-Drilling Tools Greatly Increase Mold Builder’s Gun-Drilling Productivity that had Previously Limited Faster Mold Production

New drill tools for deep-hole drilling increased feeds, speeds, reduced tool-change downtime, helped company avoid purchasing a backup gun drill.

Read MoreHow to Use a Conformally Cooled Sprue Bushing to Reduce Cycle Time and Ease Cost Pressures

Use of a new conformally cooled sprue bushing helped solve Midwest Mold Services’ problem with a big sprue that was hard to cool and preventing faster ejection times.

Read More