Solving Ejection Problems

Part of the Vangest Group, moldmaker 3DTech (Marinha Grande, Portugal) is strategically located in a technology corridor filled with automotive, consumer electronics and electrical-component companies. 3DTech specializes in precision injection molds in hardened and prehardened steel for medium-to-high-volume production runs for presses from 6.5 to 2,000 tonnes/tons. In addition to conventional injection molds, the company also produces tools for 2K, 3K and transfer molding and gas-assist injection — with most tools complex enough to require tooling action.

Torture Tools

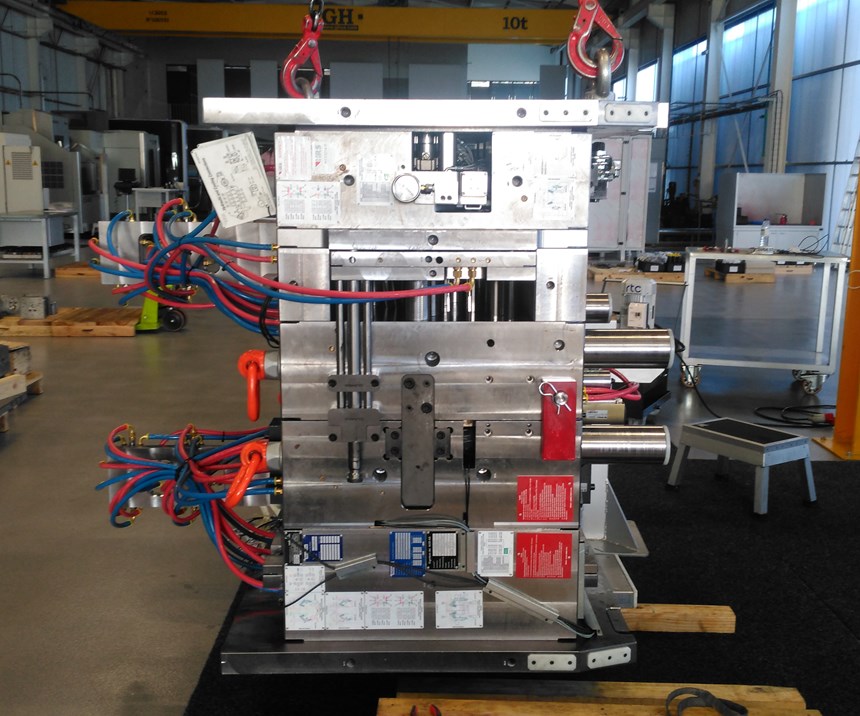

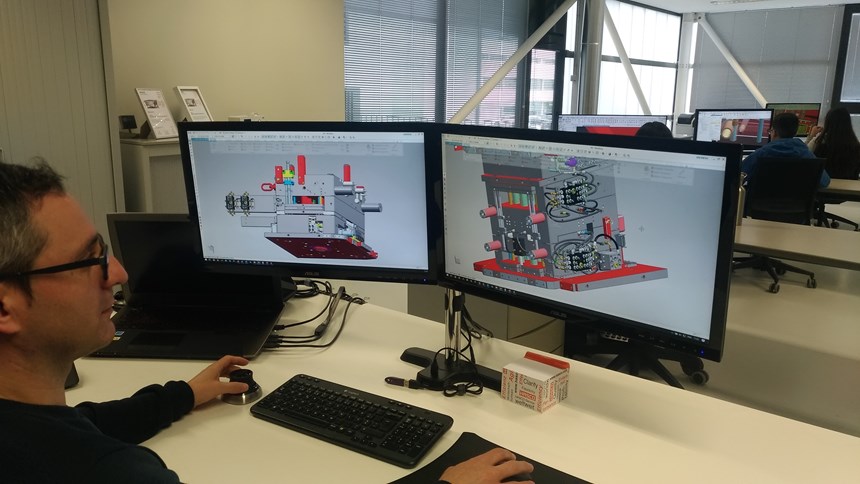

3DTech builds lots of automotive tools. In 2018, it found itself having to produce a pair of very complex tools to injection mold door handles for a German carmaker. The program was already tight on deadline when the job arrived, so João Caetano, 3DTech design team leader, got right to work, and immediately ran into many design challenges.

- Each door handle — which was 200 by 330 by 105 millimeters/8.0 by 13 by 4.3 inches with a nominal wall of 2.5 miliimeters/0.10 inches and containing rear-side geometry — had 12 undercuts: three on the A side and nine on the B side.

- The polished B side of each handle required a large lifter. Below this lifter, a hydraulically controlled slide was needed.

- Based on probable locations for the sequential valve gates and the need to hide parting lines inside the B side while maintaining a smooth surface that didn’t chafe fingers during use, each undercut would require its own lifter, and three of them would have to reside on the fixed side of the tool. One lifter would be placed near an injection gate and one would produce the parting line. However, a large A-side lifter would have to retract using less than a 42 degree working angle — a very aggressive target that required a special cooled-rack lifter solution.

- To prevent sinks in a thick section, the team added gas-assist and placed the gas port near the first valve gate on each cavity. Later, during tool tryout, they added a second gas port to each cavity to more rapidly cool parts and bring total cycle time down to 65 seconds.

- Given all the action in the tool, and how large each handle was, the mold already would be tall (almost 1,400 millimeters/55 inches) and would require a large stroke on the moving side of the press to produce parts (almost 150 millimeters/6.0 inches). Unfortunately, the press planned for this job wasn’t equipped with a particularly big daylight opening, so a single four-cavity mold wouldn’t fit. Hence, two tools would be needed (two cavities/mold for left and right sides of front and rear door handles).

“This tool was very difficult for me,” recalls Caetano. “I am the project responsible leader for our design team and I had to leave my team to work alone so I could concentrate on this project. With six lifters on the fixed side of each of these molds — three per cavity — it was going to be a real challenge to open and eject this tool. And because work on tool design took longer than expected, owing to the complexity involved, the milling process had to run very fast at the end, making things a bit of a nightmare.”

Ejection Strategy

As if trying to design and build two very complex tools in less than four months wasn’t enough challenge, Caetano had no good options for ejecting parts. He needed a three-stage plate separation strategy for each cavity to preopen hydraulics on the slides, move all lifters out of the way and eject on the fixed side of each tool. Using hydraulics to actuate A-side lifters wasn’t as an option. “First, we had to follow the mold opening and we wanted to decrease pressure applied in the mold to keep tool action smooth,” he explains. “Also, the big B-side slide for each cavity was controlled by two hydraulics, so we needed four hydraulics just for this feature, and I only had eight for the whole tool. In the end, there is only so much plumbing you can add.” That meant that A-side ejections would need to be controlled purely mechanically.

There already were internal mechanical ejectors on the market, but they were only available for smaller molds — too small for the size and weight of these tools. A few companies offered external mechanical ejectors, but those were too small, none offered multi-stage ejection in the orientation he needed and 3DTech’s previous experience wasn’t overly positive. “We had used some external ejectors a year before, but our factory guys were always complaining because they made noise when they worked, and we felt that something could break,” adds Caetano. “Also, since they were for smaller tools, we had to build bridges to connect them to make them long enough to use. All of them were just too fragile, and they didn’t give us confidence to use in a tool of such dimensions and weight.”

After pouring over parts catalogs, checking the internet, and talking to colleagues at other Vangest businesses, Caetano resigned himself to building something custom. That’s when a team from EuroCumsa, a supplier from which 3DTech regularly purchased standard components, showed up to discuss a development product that might just solve his problems.

New Solution

3DTech has worked with Barcelona-based Cumsa— a company that designs, manufactures and distributes standard solutions for the moldmaking and molding industries — for many years and several Cumsa components already were specified on the door-handle molds, including the cooled-rack lifter.

Cumsa is known for its high quality, simple and innovative component function, and ease of assembly and adjustment of its moldmaking components. The company was formed in 1979 by a group of Spanish moldmakers seeking markets outside Spain. By the early 1990s, Cumsa was taking advantage of its knowledge of tooling and the day-to-day challenges of molders and moldmakers to build its own moldmaking components when ready-made solutions were unavailable. Word got out and other moldmakers sought these components, which led Cumsa to form a standard-components business with its first office, EuroCumsa, in Marinha Grande. Other locations soon followed in Europe, Asia and North America. So successfully has the standard-components business grown over the years, that Cumsa sold its molding operations several years ago and now strictly focuses on finding standard-component solutions for injection molders and moldmakers.

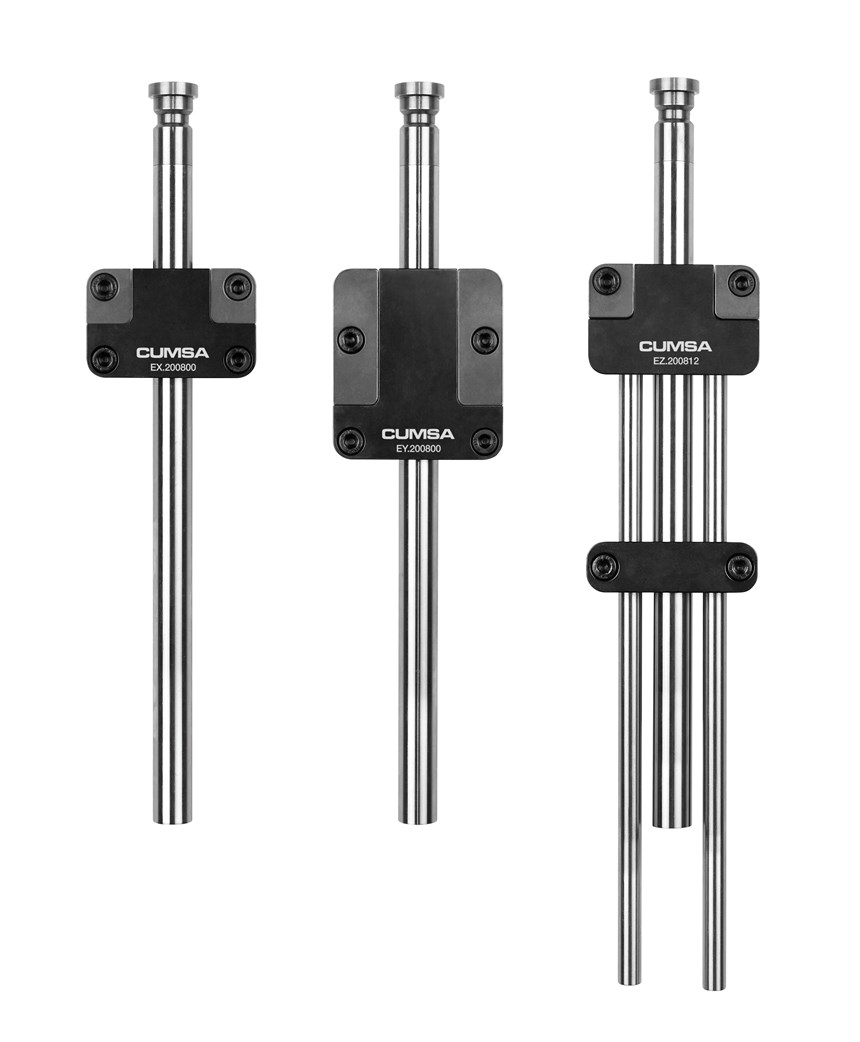

The Cumsa team showed Caetano a developmental external-ejector system it planned to launch at K2019 in Düsseldorf, Germany, the following year. Caetano was intrigued. “I try almost everything they do because Cumsa makes some kinds of parts that other suppliers do not,” he explains. “They always try to invent and put on the market things we really need but normally cannot find.” The Cumsa team showed early concepts of a purely mechanical, external superior-plate separator for the X axis (called EX) and an external double-ejection system for the Y-axis (called EY). The concepts could manage a two-plate separation strategy and were big and robust enough to work on the door-handle molds.

“They showed me their concepts and I said ‘They were very nice, but I have a special tool and I have to find a quick solution,’” Caetano recalls. “I proposed a different solution, for them to adapt their system to our tool to give me three-plate separation in the Z-axis. The guy was very interested and understood this could be the kind of part that we don’t have on the market, so he goes back to find a solution. He knows that João is trying to do something impossible again.” Within days, the Cumsa team was back with a new solution that eventually became a commercial product called EZ to control external synchronized plates in the Z-axis. “This was a very strong and good solution,” adds Caetano. “I didn’t have to tear apart my tool to put it in. It was very easy to assemble and tune. I just had to cut simple rods and put them in the right position. And it is very easy to maintain.”

Since each of these tools contained two cavities, Cumsa built four EZ controllers for each tool (eight in total for the job), and 3DTech drilled holes for their assembly. However, during tool tryout, the team decided to see if the system would work with just two units/tool — and it did. They worked so well that the extra units immediately were used in another tool 3DTech was building simultaneously.

Normally, Cumsa recommends using a pair of the external double-eject systems (either EX, EY or EZ) — one on each side of the cavities where the ejections will take place. Since each of these tools contained two cavities, Cumsa built four EZ controllers for each tool (eight in total for the job), and 3DTech drilled holes for their assembly. However, during tool tryout, the team decided to see if the system would work with just two units/tool — and it did. They worked so well that the extra units immediately were used in another tool 3DTech was building simultaneously. “Even better, what surprised me and my guys is how smooth and quiet these parts work, which gives us confidence that we have the right solution,” he adds. The tool was delivered to the automaker in February 2019 and went into production the following month without issues.

“When you need synchronized control of plate movements, these controllers are very helpful,” says Silvia Navarra, CEO/general manager, Cumsa USA. “Trying to use homemade approaches with hydraulics and sensors is more complex, more work and more cost, plus sometimes they work and sometimes they don’t.

“For most toolmakers, the good price and simple installation and maintenance of these systems will save time and effort, and make their molds more cost-competitive,” adds Rui Rocha, general manager, EuroCumsa.

“Cumsa is truly a partner-supplier for difficult solutions,” concludes Caetano. “I am so glad they have offered something strong to use outside the tool that works for big molds. They now offer four sizes each for the three systems, which makes them a very good solution.”

Related Content

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

External Double Ejection Systems Designed to Control Sequence of Plate Openings

CUMSA’s double ejection systems were designed to control the sequence of double ejections or plate openings.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)