EnvisionTEC, Covestro Develop Industrial 3D Printing Solution for Rapid Injection Mold Tooling Production

Covestro DLP resin e-PerFORM used with EnvisionTEC’s Perfactory P4K series DLP 3D printing demonstrates faster, more cost-effective print speeds with high stiffness, high temperature performance.

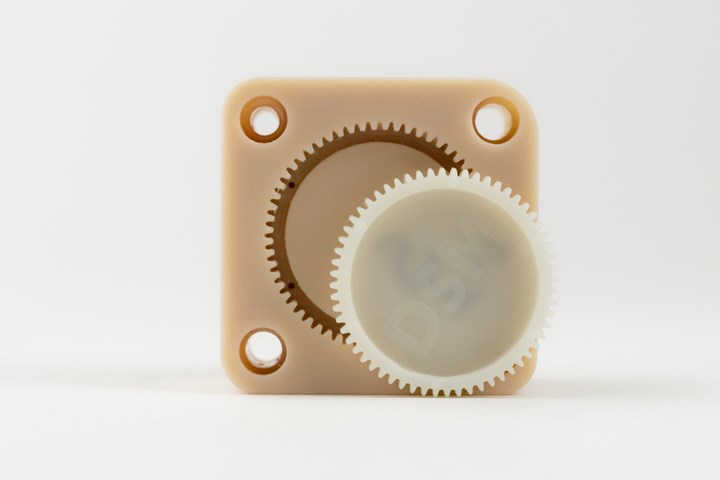

Tool used for injection molding glass-filled nylon gears is 3D printed on EnvisionTEC’s Perfactory P4K series printer using the e-PerFORM resin. Photo Credit: Covestro, EnvisionTEC.

EnvisionTEC (Dearborn, Mich., U.S.), a wholly owned subsidiary of Desktop Metal, and polymer company Covestro AG (Leverkusen, Germany) have announced a collaboration on material+printer solutions to accelerate the adoption of industrial 3D printing. Together, the two companies aim to lower the entry barriers for companies looking to adopt 3D printing for producing molds for low volumes or parts with detailed features faster and more economically.

The combination of Covestro material expertise and EnvisionTEC printer technology has resulted in a complete industrial manufacturing solution for 3D printing injection mold tooling. According to the partners, until now, no solution was available that met the stringent industry-required properties in terms of dimensional stability and minimal warpage. The patented material formulation from e-PerFORM, optimized for EnvisionTEC’s equipment, reportedly brings the benefits of Somos PerFORM to a faster and more economical printer technology.

To bring customers a workable and demonstrated material+printer solution, EnvisionTEC and Covestro optimized print parameters and verified Covestro’s new DLP resin e-PerFORM on EnvisionTEC’s Perfactory P4K series printer. EnvisionTEC further tested e-PerFORM resin with key molding institutes to validate the material’s performance. Completed mold trials demonstrate that e-PerFORM resin, with high stiffness and high temperature performance, behaves similarly to stereolithography resin Somos PerFORM for injection molding tooling.

Tests performed by Polyvia, the French Federation of Plastics and Composites, are said to have confirmed the suitability for rapid tooling. Guy Chrétien, process project manager at Polyvia notes: “We tested the new e-PerFORM resin printed on the EnvisionTEC P4K printer and demonstrated that we could achieve very good results in part fidelity and in the number of shots molded in both polypropylene and glass-reinforced nylon. With the cost effectiveness and print speed of the P4k platform and with the properties of the e-PerFORM resin, this creates additional opportunities for rapid tooling.”

“The combination of our P4K printer and Covestro e-PerFORM optimized for our printers enables fast, cost-effective production of injection molding tooling,” says Al Siblani, EnvisionTEC CEO. “Our collaboration has resulted in a new and much-needed solution.”

The combined solution of Covestro DLP resin e-PerFORM on EnvisionTEC’s Perfactory P4K series DLP 3D printing is being presented this week at RAPID+TCT in Chicago at Covestro booth #E7212 and EnvisionTEC booth #E7501.

Related Content

-

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

-

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

-

In "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

.jpg;maxWidth=300;quality=90)