Rapid Prototyping: Is It a Commodity?

When considering a rapid prototyping bureau, it may be more cost-effective in the long run not to look at RP as just another commodity.

A commodity is a physical item that is interchangeable with other products of the same type and is sold primarily in quantity.

An increase in industry rapid prototyping (RP) capacity, along with a decrease in demand for prototypes caused by a downturn in current economic conditions, leads many to believe that rapid prototyping has become a commodity. If rapid prototyping is a commodity, then any stereolithography (SLA) prototype is interchangeable with any other SLA prototype, the only question being how many parts are needed. Rapid prototyping machine suppliers, who advertise ease of use and high-quality prototypes that come directly out of the machine, intimate that all RP parts are created equal. This simplified view does not represent the many new technologies and trends of the industry. These technologies include the use of new materials, the achievement of greater levels of accuracy, options for multiple finish levels, new decorative coatings and fully functional electromagnetic interference (EMI) coatings. Finally, the trends of supplier/customer interaction (i.e., making last minute changes such as file updates and design changes) and supplier availability are important and productive benefits that distinguish quality providers.

A prototyping program is critical to getting answers to questions regarding product development. Capitalizing on the latest technologies differentiates a high payback prototyping program from one that provides only limited solutions. An effectively designed RP program helps to determine when to treat RP as a commodity and how to identify new capabilities that can greatly enhance the user's return on investment.

For an item to be considered a commodity, it has to be extensively used and available from many sources. Additionally, capacity has to be sufficient enough to allow the laws of supply and demand to influence pricing. In other words, at times supply has to exceed demand. For these reasons, only two rapid prototyping technologies will be considered. These two are SLA and selective laser sintering (SLS). These technologies are predominately used by service bureaus. While clearly there are many more rapid prototyping technologies that are widely accepted, the principles examined in this article can be applied to a lesser degree to the other RP technologies.

SLA and SLS

For the purposes of background, stereolithography is a rapid prototyping process that uses a UV laser to selectively cure an epoxy photopolymer into a solid object. SLS is a rapid prototyping process that uses a CO2 laser to selectively sinter plastic powder into a solid object. Both processes start with a CAD file that is preprocessed to select the best part build orientation and placement within the machine. Machine parameters are selected and the part is electronically "sliced into layers." The layers are built one at a time on top of the previous layer until a complete part has been constructed.

Background

Traditionally, the three questions that would be asked when one considered selecting a prototyping program were: What type of prototype do I need? When do I need it? and How much is it going to cost? In the 80s and early 90s, these questions provided direction because of the limited choices. The prototype was about actual size and had to be handled carefully to be sure that it made it through a design review meeting. Limited material choices made the decisions less complicated. Limited supply gave the engineer few pricing choices. In those days, snap fit meant plenty of snap and limited fit.

In the early 90s, new SLA materials changed the decision-making process, requiring a rethinking of the application of rapid prototyping. SLA introduced more durable materials that opened up a new range of applications. At the same time, the supply of SLA models became more readily available. The technology spread quicker than the expertise to use the technology. The mantra became: "Buy an SLA machine; become a service bureau."

The application expertise did not keep up with the technology. Rather than becoming specialized, the industry became more generalized. This generalization has since driven the engineering profession to believe that all RP is created equal. The industry begins to become perceived as a commodity where price and quantity drive the buying decision. In the context of the commodity definition, any SLA could be replaced by another SLA. There are times when it is true that any SLA model is as good as another; however, for a large percentage of prototyping programs, asking a few more questions will lead to a significantly larger payback.

When Is Rapid Prototyping a Commodity?

Rapid prototyping is a commodity when:

- You need a prototype extremely fast or budget constraints overwhelm other concerns.

- You are having trouble visualizing a part on the computer screen.

- A toolmaker needs to see a feature rather than just interpret the drawing.

- Aesthetics and accuracy are much less important than getting the prototype in hand quickly.

- It breaks after the first hour and it will not be a problem.

These situations occur during the design process on a regular basis and are all addressed by answering the "what," "when" and "how much" questions. Options exist today to download a file to a website, get an instant quote and order the part. As soon as two days later, the part can be in your hand. The engineer's needs are met, information is obtained and the prototype is set aside. There are times, however, that will lead to a different view of the prototyping program by asking what else can the prototype accomplish.

When Is Rapid Prototyping Not a Commodity?

Expanding on the "what," "when" and "how much" questions leads to a different set of options. For example, the "what" question needs to address the intended purpose of the prototype. The "when" question needs to address multiple parts and the overall project schedule. The "how much" question needs to be viewed in the context of the entire prototyping program.

The "What" Question

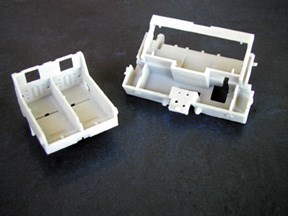

New materials and processes have transformed rapid prototyping. The integration of new technologies into existing technologies, like different laser spot sizes, have resulted in many more choices than existed just a few years ago. If an engineer needs a functional prototype that can withstand temperatures to 180'F, or if the engineer believes that the prototype may be handled at many locations, especially by people who believe it is a production part, then the appropriate, durable prototyping material needs to be used. Rather than ordering an SLA part, the engineer should consider an SLS part or a combination of the technologies to make up the assembly. SLS parts are typically chosen when the mechanical properties of the prototype are critical. Figure 1 shows GF Nylon SLS parts that were used in a working printer assembly and used to verify complete function of the print head.

Once a technology and material have been selected, the appropriate finish level can play a significant role into the usability of the prototype. Multiple finish levels ranging from "strip and ship" to painting are available. Within that range there also is a wide perception of definitions. One man's pattern finish is another's functional finish. In other cases, sanding to a pattern-level finish removes all of the critical details that a CAD designer spent an extra two hours modeling in the design. Generally, the finish levels can be broken down into three major categories. The first is "right out of the machine," called "strip and ship" or "support removal and light sanding." The cost savings are attributed to minimizing the hand labor to remove build artifacts, such as layer lines and support marks, from the part. Layer lines can be hidden, but they are not removed unless done by hand.

The second category is removal of some of the build artifacts. Usually this is done selectively to minimize the amount of hand labor in post processing. With some customer dialog, the critical surfaces can be determined, and those surfaces can be hand finished to remove the build artifacts.

The third category is a complete hand working of the part to remove all build artifacts. The purpose of this level is to prepare a part to be used as a pattern or to prepare the part to appear as a production part. This level also is used to finish parts and to make them clear, provided that the material selected is clear. Figure 2 shows an SLA assembly using DSM 10120 resin finished to clear.

When the prototype is to be used to represent a production part, painting and decorative coatings can be used to provide that look. Parts need to have all of the build artifacts removed and they need to be primed. The finished, painted part can appear to be a production part. In addition to painting, techniques to simulate production texturing have been developed. A wide range of production textures can be selected. When needed, the textured parts can be used as a master in silicon rubber tooling and the resulting urethane castings will have production textures.

To take the prototype to the next level of production, decoration coatings can be applied to simulate carbon fiber, or production camouflage coatings can be applied to provide production aesthetics. Figure 3 shows two carbon fiber coatings and a camouflage coating. All can be applied to SLA prototypes.

To make prototypes completely functional, EMI coatings can be applied. These EMI coatings have the same EMI properties as production EMI coatings and the prototypes can be used to fully test EMI properties.

Proper selection of material and finish still does not ensure that the prototype will meet the project specifications. "Strong enough" and "smooth enough" will not help if the part isn't the correct size. Rapid prototyping parts can vary widely in dimensional accuracy. Materials age in the machine, lasers drift, processing parameters change slightly - all leading to an extra .002 in. in tolerance. The difference is the difference between a cover and an assembly half fitting together or two parts that don't fit together, and raises the question as to whether it is a design problem or a prototyping problem. This is especially problematic when the features that appear to have a problem do not lend themselves to an easy measurement. The best solution is to ensure that the rapid prototyping equipment used is calibrated and that the service bureau prioritizes accuracy.

The "When" Question

When do you need the part? Often, there is not a simple answer. Multiple parts, designed by multiple designers, usually result in designs completed at different times. When CAD software that verifies that there are no interferences is used rather than waiting for all parts in a project to be completed, it may be best to first release only one or two parts to prototyping and then release the balance of the parts in phases. If some of the parts are patterns for other processes (i.e., rubber molding or composite tooling), early release of those parts can save the overall project a significant amount of time.

Is it best to get the first parts with less finishing to save time? If there are portions of the design that will not be completed for some time, is it best to prototype the current design to remove risk prior to completing the design? The answers to these questions can change the way in which parts are released for prototyping and can positively impact the required delivery. Sometimes parts are needed in two days; however, sometimes parts need complete finishing to ensure total accuracy to take the maximum amount of risk out of the program. An analysis of the trade-offs can determine whether delivery time or surface finish is most critical to the program.

The "How Much" Question

Answering the questions raised previously leads to many options. Each option will have a different cost. A pattern-level finish will cost more than an unfinished part. A service bureau that spends time and money on ensuring accurate parts will need to charge more for an SLA model than a service bureau that builds parts without constant monitoring of accuracy. A change in a downstream process also can have a dramatic effect on overall project prototyping costs. For example, if the purpose of the prototype is to create a pattern for urethane castings and the urethane being used has a large shrink factor, two patterns will be needed rather than one (one without a shrink factor applied to verify the designer's intent and one with a shrink factor applied to be used as a pattern). If the only objective is to get an SLA model fast, then price can be the determining factor. In this case, rapid prototyping can be a commodity; however, if after further analysis the prototype is found to have multiple uses and can solve other design issues, a low-price SLA prototype commodity option may be limiting.

One More Issue

When all of the prototype-specific questions have been answered, the issue of selecting the correct file still needs to be addressed. Files are often released for prototyping with errors as simple as large tessellations and areas that have thin walls. These types of file errors will not be detected with an automatic file verification process. Compounding this issue is the selection of the correct build orientation for the part. The optimum quote orientation is not always the optimum build orientation. Placement of supports, critical tolerance areas and fit-up with mating parts all require analysis to ensure a prototype that meets the customer's needs. All this assumes that the file that was quoted and ordered is the correct file. The last-minute call to a service bureau immediately before a part is built to execute one more design change is all part of the process. Making a service bureau a member of the team can make the entire RP process work smoothly and not only save time, but also make the overall program more cost-effective.

Conclusion

While there is currently a move to transform rapid prototyping into a commodity, this move fails to take into account some of the main reasons why engineers use rapid prototyping. Getting the maximum amount of information about a design as early as possible has driven dramatic growth in the industry. Com-promising the amount of learning about a design for ease of ordering or upfront cost savings can be counterproductive and, ultimately, not cost-effective. It has been proven that rapid prototyping is an investment with returns many times over the initial costs. Taking that same thought process and applying it to the entire prototyping program leads to an analysis of how to apply the newest rapid prototyping techniques for maximum payback. A commodity perspective simply looks to save money by purchasing in quantity; a rapid prototyping program selectively applies technology to save money. Finally, a commodity purchase gives little thought to the seller. The commodity is the item of interest.

In rapid prototyping, making the seller - a service bureau - a partner in the process will allow the engineer to take full advantage of the service bureau's capabilities and expertise and, therefore, get maximum payback from the investment in RP.

Related Content

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read More3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

Read MoreMold Materials, 3D Printing Technologies for Next-Gen Moldmaking

As moldmaking advances, so too do the materials and processes involved in their efficient production, including these latest mold materials and 3D printing technologies.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)