Benefiting From Hot Runner Design and Reliability

Selecting a hot runner system designed with the moldmaker and end user in mind has helped a moldmaking shop remain competitive.

St. Clair Plastics (Chesterfield, MI) has met the challenge facing many North American moldmakers - delivering high quality products at competitive prices. Achieving this has resulted in some very interesting approaches to the use of hot runners in its tooling programs.

Since it was founded in 1951, the company has grown through constant change to become a niche market player to the automotive industry. Its molded products include a wide range of automotive door and window components and assemblies including interior trim components. St. Clair Plastics also designs and builds its own automation equipment as part of the value-added services that it brings to the manufacturing process.

When St. Clair Plastics designs a mold, it looks at the operation and maintenance of that mold and what it can do to maximize uptime. As a moldmaker and custom molder, it understands the close relationship between the two that is necessary to survive in today's competitive marketplace. Keeping its moldmaking operations busy has been a major part of the company's business strategy. It also is very adept at working with other moldmakers to meet delivery deadlines when the shop is too busy.

St. Clair Plastics' moldmaking and molding capabilities extend from producing simple mechanical components to complex products with inserts, over molding and the use of multiple materials on presses from 95 to 1,000 U.S. tons. As part of its philosophy, the company has established a machine replacement program that ensures that the average age of its molding machines is less than seven years.

The Right Choice

Although Stewart Baetz, toolroom manager of St. Clair Plastics, has only been with the company for just over a year, he brings more than 30 years of industry knowledge to it. He was the first to introduce the company to the idea of using a single hot runner system for multiple molds. Not every part may require the use of a hot runner - or could justify the cost - but those that do can benefit from the idea of interchangeable hot runners. Now when St. Clair Plastics designs a mold, it looks at part design, materials, production volumes and required cavitation to first determine if any of the existing hot runners can be interchanged before buying a new hot runner system.

It also has standardized on one brand of hot runner for several key reasons. Prior to joining St. Clair Plastics, Stew Baetz had been involved not only in specifying hot runner purchases, but also evaluating the features of all of the major brands - domestic and imported - available in the United States. After testing each of them in various applications, he was able to identify the key features that he required to meet his performance and cost criteria and then select the best hot runner system to achieve this.

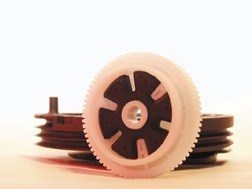

Having worked closely with PCS Company (Fraser, MI) for many years - using its mold components and mold bases for his molds - he quickly became aware of the complete bolt-on hot runner systems that it offered from CTI (Caco Technologies Incorporated) and included them in his tests. The results spoke for themselves and he selected the CTI hot runners available from PCS Company over the others. PCS Company is recognized for its complete line of mold components and high quality mold bases.

Baetz recognized very quickly from the various features present with the CTI hot runners that they were clearly designed with the moldmaker and end user in mind. The various features were intended to simplify their use and eliminate as many potential problems as possible. It also was evident in working with CTI - when specifying the hot runner - that the company could apply its knowledge and experience to assist with the mold design and make suggestions of ways to simplify or improve the overall mold and its performance.

St. Clair Plastics also wanted to be able to change a hot runner system in 30 minutes or less in order to keep its total mold change times to a minimum. Typically, St. Clair Plastics may perform as many as two or three mold changes per machine a day because of the short production runs it faces. With the interchangeable hot runner system, it only needs to remove eight bolts - four per mold side - and move the hot runner system from one mold to another.

Solving Challenges

One of the biggest challenges faced by molders using hot runners is with start-up. Almost every molder can share a story where a manifold has not been brought up to temperature before the first shot and everything leaks into the hot runner system, destroying the thermocouples and wiring. It is bad enough having to take a hot runner system completely apart to clean it and then re-wire and assemble it, but with engineering grade resins and high glass content, the challenge and task is made that much more difficult.

Finding a system that is truly "leak proof" was very important. St. Clair Plastics has never had a single problem with leakage with any of the CTI hot runner systems, which is one advantage over other systems. Being able to easily maintain the hot runner in the machine if there are any minor problems also is critical to the company. Having the thermocouple located close to the flow channel gives it precise heat control of the molding operation for increased productivity with better molded parts and less scrap.

Having the heating element copper clad and embedded in the manifold eliminates hot spots for maximum thermal conductivity and increased heater life. The embedded copper-clad heaters help prevent problems and maintenance issues resulting from cracking and chipping of the bonding materials used in some other hot runner systems. The even heat transfer from the copper-clad heaters in the manifold also results in reduced power consumption.

St. Clair Plastics has found that the benefits of interchangeability extend beyond the hot runner manifold system to also include the CTI Interactive Process Manager (IPM) hot runner temperature controller. The company is able to move the controller with the hot runner system or simply disconnect it from one hot runner system and connect it to another.

The controller plugs directly into quick connects mounted on the hot runner system and is held in place with two flip latches - allowing a changeover in less than a minute. Start-up is simplified as the controller virtually handles everything to get the hot runner up to temperature much faster. The controller can store multiple mold setups for maximum interchangeability. St. Clair Plastics also has the flexibility to use either the handset supplied with the controller or a laptop computer for programming when adding a new mold or changing the existing parameters. Both are connected via a line from the controller. St. Clair Plastics has found the controller to be simple to operate and can fully train most users in a single afternoon.

The hot runner temperature controller also provides the company additional flexibility when interchanging between hot runners, as it provides complete diagnostic feedback and a high degree of control across a wide temperature range. This is especially important to St. Clair Plastics, which processes a wide range of composites requiring very tight control. A standby temperature setting can be set easily on the controller and it automatically lowers the temperature when the molding machine cycle is interrupted. This helps eliminate degradation of material due to overheating during cycle interruption.

The controller also has the ability to automatically record any changes that are made to the temperature settings or set parameters of the controller including details of the specific changes. This has a great advantage for achieving ISO standard molding operation at all times. Multiple recipes for different molds can be stored within the controller and can be easily recalled for fast mold setup.

Reducing Leadtime

Minimizing leadtimes is another issue that St. Clair Plastics always must keep in mind. However, buying an off-the-shelf system is not an option, as each manifold is built to a specific application. The company has found that there are too many variables in terms of drop height, plate thickness, bolt patterns, etc., that need to be taken into consideration. Its experience with the custom bolt-on hot runner systems has been excellent and delivery is never an issue, as it has always received its hot runner systems ahead of schedule.

Ensuring that any downtime also is kept to a minimum was a key issue in selecting the hot runner system. For St. Clair Plastics, this meant ensuring that the hot runner system could truly be maintained in the machine with little difficulty. From quick cool down to allow access to the hot runner system, to ease of maintenance when removing heater bands and thermocouples, all played a role in its selection.

Where interchangeability might not at first seem like an option because volumes may increase quickly for a program and require a dedicated hot runner, St. Clair Plastics realizes that it can always buy an additional hot runner when required. One key benefit of interchangeable hot runner systems is obtaining all of the advantages of a hot runner for applications that previously would not have justified the investment.

Selecting a hot runner system designed with the moldmaker and end user in mind has helped St. Clair Plastics remain competitive in an increasingly challenging marketplace. Bill Burns, president of St. Clair Plastics, recently thanked Baetz for his determination and efforts to convince the company to standardize on CTI hot runners and has since described it as the best decision that the company made.

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreRead Next

Hot Runner Justification

How OEMs, molders and moldmakers can better determine when it makes sense to use hot runner technology.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)