Build

How to Select and Use Your Vertical Machining Center

Competitive shops need to consider the true capabilities of their VMCs to achieve a high level of accuracy and surface finish.

Read MoreHow to Implement Ultra Productive EDM

Steps to help maximize the potential of your current die sink or wire EDM system.

Read MoreBurning Bright

EDM experts reveal that trends in increased automation combined with unattended machining result in better accuracy and surface finishes in wire and diesinking EDM applications.

Read MoreHow to Justify Your Hot Runner Purchase

Four questions to help with hot runner justification.

Read MoreAutomation Increases Throughput

The addition of an automated cell helps moldmaker/prototyper increase efficiency and speed.

Read MoreAre All Graphites Created Equal?

Five key performance factors to consider when selecting your graphite grade.

Read MorePart One of a Two-Part Series Valve Gate Sequencing Strategies

Ways to use valve gate control strategies to improve quality, efficiency and profitability

Read MoreThe Key to Better Electrode Making

Smooth out the process, eliminate unnecessary steps, reduce errors and automate repeat work by using a single software solution throughout electrode design and manufacture.

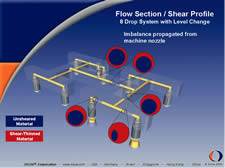

Read MoreImproving Shear-Induced Imbalance in Hot Runner Systems

Even melt distribution and balanced filling to and across all cavities while avoiding restrictive mixers is possible with hot runner manifold construction that incorporates a melt rotation design.

Read MoreUsing CAD Data to Build Molds By the Numbers Can Reduce Costs and Leadtime

Crucial initial decisions must be made before machining begins.

Read More