Build

Wear Parts and Consumables: The Keys to Maximizing Your EDM

Mold shops need to pay attention to the potential impact wear parts and consumables can have on their overall production.

Read MoreRapid Tooling Via Stereolithography Gets a Closer Look

Industry roundtable reports initial findings.

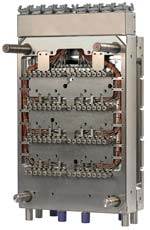

Read MoreMaintaining a Strong Relationship with Your Hot Runner Supplier

Once your hot runner supplier is chosen, you need to take the proper steps to maintain a mutually beneficial, long-term relationship.

Read MoreUp Close and Personal

Getting up close and personal with the latest current and emerging technologies affecting the mold industry is the best way for mold manufacturers not only to see what is out there.

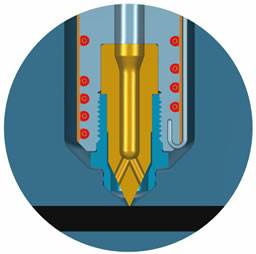

Read MoreSelecting the Right Gating Method for Your Application

Designers may select among four hot runner gating methods, each with its advantages and disadvantages.

Read MoreHow to Choose the Right Tool Coating for Your Machining Application

Selection criteria and common coating attributes for PVD, CVD and other common coatings.

Read MoreThree Influences that Are Critical to Mold Performance

Analysis, integrated design and value-engineering play an important role in choosing the right hot runner supplier.

Read MorePart Two of a Three-Part Series Five Steps for Improving Your Shop’s Maximum Productivity Part 2

The reasons and justification behind moving your component finishing operation from EDM sinking to hard milling with the right machine, software, cutters, toolholders and training; and how you can add machine time to your shop through lights out machining.

Read MoreLooking Sharp

Advancements in cutting tool/toolholder construction yield better stability and higher accuracy to achieve greater feedrates and increased productivity.

Read MoreHow to Exceed the Limits of Your Toolpaths

A moldmaker’s ability to reduce machining time is not limited by his machine tools or cutting tools, but rather by the toolpaths that drive them.

Read More