Build

Additive Fabrication Can Be A Real Plus in Your Shop

As mold manufacturers across the country work to grow and succeed, regularly examining the new and existing technologies on the market.

Read MoreExtreme Tool and Engineering: Building Relationships, Fostering Growth

This moldmaker proves that dedication to its customers combined with a will to thrive in a global marketplace is the right formula to win the MoldMaking Technology 2006 Leadtime Leader Award: Large Shop.

Read MoreA Double Whammy

The solution to solving problems associated with EDMing high copper alloy work metal involves finding the right graphite electrodes.

Read MoreMaking Lean Work: Autonomation

Transferring human judgment to automated machinery can increase shop production.

Read MoreOpportunities for Mold Shops with Micro Molds and Micro Milling

Learning about the trends and challenges with micro molds and micro milling will help shops maintain their competitive edge.

Read MorePart Three of a Three-Part Series Five Steps for Improving Your Shop’s Maximum Productivity

An explanation of the differences between high-speed machining and conventional machining; and, general thoughts on when to high speed machine and heat treat versus hard milling.

Read MoreThe Keys to Successful High-Speed Machining

Moldmakers will reap all the benefits of high-speed machining with the right mix of machine tool, tooling and programming.

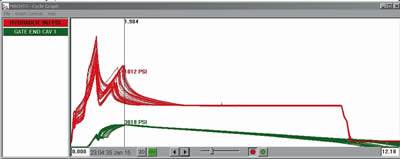

Read MoreSetting Up a Robust Process Forever

Deciding how to process a product with the least amount of part variation over the long term.

Read MoreMold Building Without Rule Breaking

Push the mold in the beginning of the build process to discover any weaknesses before it gets to the molder.

Read More