Build

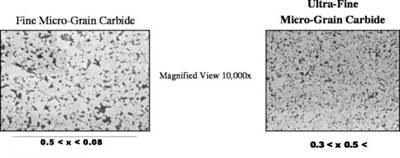

Advanced Cutting Tools Translate To Greater Cost Savings

Increasing initial tooling investments will allow moldmakers take home more profits at the end of the day.

Read MoreStandardized Mold Building Makes Shortened Leadtimes Possible and Profitable

The next level of standardization has allowed moldmakers to rethink their processes and deliver the same high-quality molds, while continuing to succeed and grow.

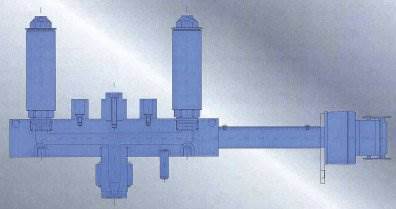

Read MoreUnitized Hot Runner Systems Reduce Errors and Save Time

Unitized and integrated hot runner systems reduce machine downtime for increased production.

Read MoreWentworth Mold: Blowing Away the Competition

Niche marketing, a commitment to technology and short leadtimes equal success for this producer of blow molds-and earns them MoldMaking Technology magazine's 2004 Leadtime Leader award.

Read MoreThe Rapid Prototyping and Manufacturing Institute: Vision Accomplished!

In seven short years, RPMI has championed the fast growth of rapid prototyping and manufacturing technologies through education, research and service.

Read MoreHot Runners Help the Balancing Process

When improving injection mold balancing, hot runners can assist in fine-tuning the balancing process.

Read MoreKeeping Your Mold Shop Competitive

To remain competitive in the mold manufacturing market every mold shop needs to answer three questions about its diesinker EDM.

Read MoreThe Value of a Well Engineered Mold Base

High-quality mold bases can help moldmakers maximize output and uptime.

Read MoreRapid Molds Produce One to Two Million Parts with a New Rapid Tooling Process

The capability of making a part using rapid tooling, as opposed to metal injection molds, dramatically reduces the time and money it takes to lead a product from the drawing board to market.

Read MoreA Different View of Faster Moldmaking

Timesaving software shortcuts and a choice of materials give a rapid prototyping shop a competitive edge.

Read More