Build

Warriors at Work

Another moldmaking industry supporter reaches out to help our veterans. Thanks to the entrustment of four new CNC machines by Haas Automation, Workshops for Warriors increased its class sizes by 300 percent. Pictured standing from left to right, Long Huynh, W for W CEO Hernán Luis y Prado, Tom Chandler, Zac Dinsmore, Clifford White, Thomas Alvarez, James Hebner. Pictured kneeling from left to right, Frank Anicoche, Shayne Schuppert, James Moreno Jr.

Read MoreHow EDM Training Can Boost Productivity

Even the shortest of training sessions provide the opportunity to recover any costs incurred in a very short time.

Read MoreTemperature Control Boosts Hot Runner Productivity, Eliminates Burned Parts

“The controllers feature a system that ‘bakes out’ moisture within the heating element at every startup. This reduces downtime—and protects the mold.”

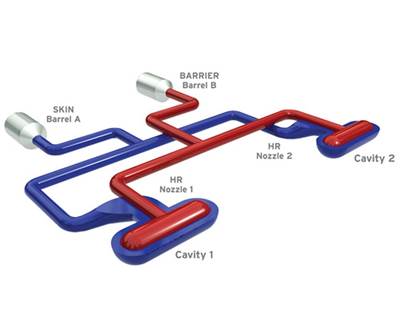

Read MoreIt’s Time to Reevaluate Co-Injection Technology

With the development of new resins, hot runners and controls technology, co-injection is positioned to move from a niche market application to mainstream acceptance in the upcoming years.

Read MoreAutomated Hard Milling Expands Capacity, Capability

“The key to investing in new machinery is to get more work done with the same amount of people, not the same amount of work with fewer people. To accomplish this, you need automated machining capabilities that are both flexible and reliable."

Read MoreTips for Successful Hard Milling of Complex Molds

And when mold and die applications demand hard milling of materials up to 66 HRC, using the right end mills, cutting parameters and machining methods is critical for success.

WatchTaking Advantage of Carbide Material for Your Mold Designs

The development of an end mill that can cut 3D features into a carbide material demonstrates how mold manufacturers can reap the benefits of carbide material for their mold designs without a time or cost penalty.

Read MoreThe Right Machine Eases Moldmaker’s Transition to Five-Axis

“This new technology allows us to be more efficient, which in turn means we can take on more work and also meet the short turnaround times our customers need.”

Read More

.jpg;maxWidth=400;quality=70)