Build

Mold Inserts Ensure Versatile Traceability Solutions

DME is providing customers with mold inserts for date, part and resin identification.

Read MoreDaters and Center Inserts Provide Continuous Quality and Reliability

CUMSA USA continues to provide continuous reliability and quality with its stainless steel original daters and center insert components.

Read MoreEjector Sleeves Extend to Greaseless Applications and Larger Size Range

From black nitride (BN) ejector sleeves, to 300 new sizes in its H-13 ejector sleeve range, Progressive Components has expanded its ejector sleeve offerings for customers.

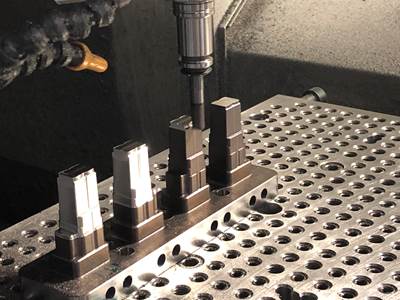

Read MoreSingle-Brand EDM Arsenal Helps Moldmaker Speed Services for Diverse Clientele

Microtech Precision sticks with Mitsubishi EDM (and milling) technology to optimize machining capabilities for molds, dies and more.

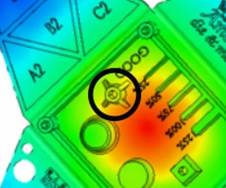

WatchWhat Is the Difference Between Knit and Meld Lines and Why Does It Matter?

Three terms that often get mixed up in the plastic injection molding industry are weld, meld, and knit lines. Meld and knit lines are actually both different types of weld lines. Here is a look at the differences between them, the causes of meld and knit line imperfections, and their impact on part durability.

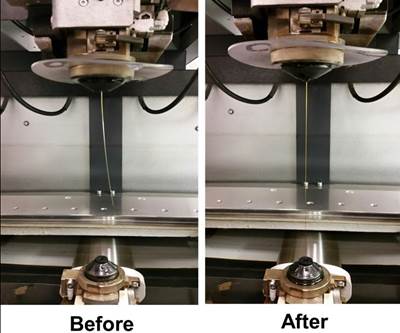

Read MoreDynamic Mold Venting Valve Resolves Poor Cavity Venting

The DMS dynamic SGD mold venting valve allows air and resin gases to dissipate via a venting channel, ensuring the production of quality parts.

Read MoreCNC Monitoring Software Improves Machine Performance and Utilization

RCO Engineering using a monitoring system to monitor setups, idle time, programming, and quality checks, reducing CNC machine downtime.

Read MorePrint the Whole Injection Mold in HSS to Increase Tool Life

A German mold builder offers a solution for printing high-speed steels with high carbon content to produce highly dense and wear-resistant molds via selective laser melting.

Read MoreCombining Customized Software with CMM Reduces Production Bottleneck

In order to reduce downtime on its EDM and CNC machines when setting up new jobs, moldmaker Kavia Tooling turned to a coordinate measuring machine from Hexagon Manufacturing Intelligence to create an offline zero transfer system ahead of the manufacturing process for parts and electrodes.

Read MoreModular Toolholder Simplifies Swiss-Style Machining

Seco Tools introduces a modular toolholder system for manufacturers seeking to improve their productivity with Swiss-style machining.

Read More

.JPG;maxWidth=400;quality=70)