Modular Toolholder Simplifies Swiss-Style Machining

Seco Tools introduces a modular toolholder system for manufacturers seeking to improve their productivity with Swiss-style machining.

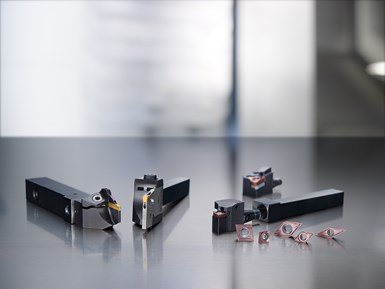

Seco Tools introduces a modular toolholder system for manufacturers seeking to improve their productivity with Swiss-style machining. The system enables fast, easy and repeatable insert indexing and tool changes outside of tight machine workspaces. The quick-change (QC) toolholders also feature Seco Jetstream Tooling and Jetstream Tooling Duo technology for optimal chip control, high-quality surface finishes and extended tool life.

For ease of use, the toolholder enables users to remove both cutting heads and inserts as a single assembly, quickly index them and reinstall. Manufacturers may also use this system to exchange cutting heads and inserts with a second set for even greater efficiency. The QC cutting head also features double carbide pins for accurate, consistent and secure insert mounting and indexing.

Jetstream Tooling technology precisely directs high-pressure coolant through the QC toolholder to the cutting zone. Jetstream Tooling Duo, available on a selection of cutting heads, adds a second coolant channel to the underside of the holder. The second coolant channel can be switched off if needed for even more versatile machining.

Related Content

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)