Build

Integrated Cascade Control Unit Ensures Control Over Melt Flow

Conscious of space, the integration of VCON with the profiTEMP+ in one cabinet enables independent valve gate nozzle adjustment for more control.

Read MoreExpanded Hot Runner Nozzle Series Focuses on Melt Guidance

Meusburger’s offers its expanded smartFILL nozzle series focusing on melt guidance.

Read MoreToolholding Collet System Generates Extremely High Clamping Forces

RegoFix introduces the powRgrip toolholding collet system, which generates extremely high clamping forces equal to and, in most instances, higher than shrink-fit holders.

Read MoreServo Valve Gate System Advances Injection Molding Process Control

Electrically driven, HRSflow’s Flexflo Evo technology is a ready-to-install system, specifically designed to set and monitor the valve pin position during the injection process.

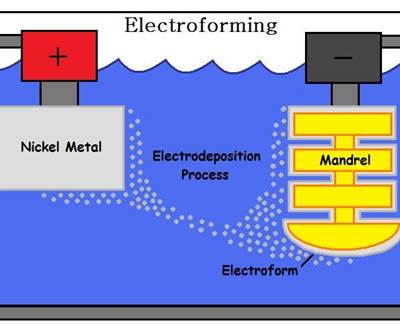

Read MoreA Multi-Metal Additive Approach to Optical Quality Molds

Researchers propose a new approach to producing mold inserts with optical surface quality and no degradation using electroforming, thermal spray, and selective laser melting.

Read MoreRoll Form Taps Ideal For Medium Strength Steels

Emuge Corp. introduces Innoform–Steel-M, a line of HSSE-PM taps designed for forming threads with improved surface quality, while increasing static and dynamic thread strength, in medium strength steels up to 44 HRC.

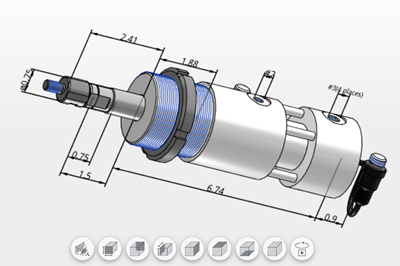

Read MoreParametric Hydraulic Locking Cylinder Models Cover All Native CAD Formats

PFA offers an enhanced user experience for all current and older versions of native CAD file formats, including Catia, Creo-ProE, Inventor and more.

Read MoreJet-Through Hydraulic Chuck Line Expanded for 5-Axis Machining

Big Kaiser expands its jet-through hydraulic chuck line to include the BCV interface and additional inch sizes.

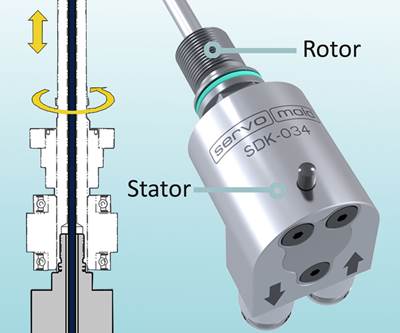

Read MoreCompact Rotary Cooling Unit Facilitates Efficient Demolding of Rotating Cores

Available as a standard unit imold’s latest product reduces development cost, eliminates problems caused by cooling water leaks and is offered in two available sizes.

Read More2020/2021 Catalog Offers Comprehensive and Versatile Tool Product List.

The Hoffman Group’s catalog comprises of quality German cutting tools, hand tools, workstations and storage options with more than 90,000 products.

Read More