Build

Hexagon Acquires D.P. Technologies

According to Hexagon, the acquisition will accelerate the development of its Smart Manufacturing portfolio.

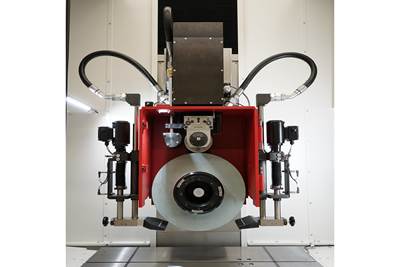

Read MoreCreep Feed Grinder Provides Exceptional Grinding Productivity

With rigidity, power and speed, the Blohm Profimat XT from United Grinding excels at machining large parts with high stock-removal requirements.

Read MoreValve Gate Nozzle Offers Exceptional Wear Resistance

Adding to Husky Injection Molding Systems’ Ultra Helix Valve Gate nozzle lineup, the Ultra Helix 250 T2’s advanced design minimizes wear, provides high gate quality and longevity.

Read MoreHow to Design a Mold with Additive Tooling

Designing molds with additive tooling implementation in mind requires blending traditional mold standards with innovative new ideas of what is possible to push the limits of mold performance.

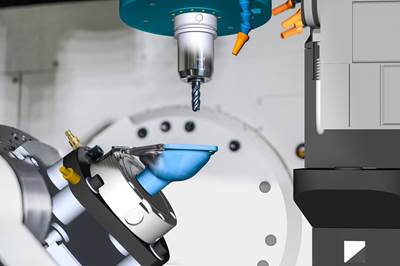

Read MoreTool Grinding Machine Excels at Complex Tool Production

The Walter Helitronic Power 400 offers precise, flexible tool production from United Grinding. A Tool Studio software heightens accuracy with a 3D simulation of parts.

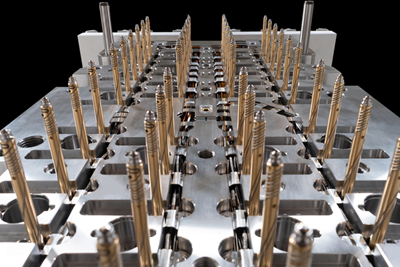

Read MoreSwitching from Solid Carbide to Indexable Tooling Permits Lights Out Mold Base Manufacturing

The unique design of small-diameter, indexable high-feed milling cutters eliminates cutter breakage, improves productivity, and allows lights out mold base manufacturing.

Read MoreInjection Mold Machined Plates Boost Flexibility

Hasco’s P1 plates, machined on all sides, come in about 2000 additional variants in dimensions, thicknesses and materials.

Read MoreFive-Axis Machining Centers Promote Flexible Machining Applications

Grob Systems offers its Access Series five-axis machining centers featuring U.S.-built basic models G350a and G550a for almost unlimited application and best machining quality.

Read MoreFive-Axis Grinding Center Delivers Flexible Workpiece Processing

United Grinding’s latest product, Mägerle MFP 30, maintains emulsion and oil coolant capabilities and has an integrated tool changer.

Read MoreAchieving Flexible Capacity with Automation

This high-mix, low-volume manufacturer embarked on a year and a half program to introduce robotics to its manufacturing process.

Read More