Combining Customized Software with CMM Reduces Production Bottleneck

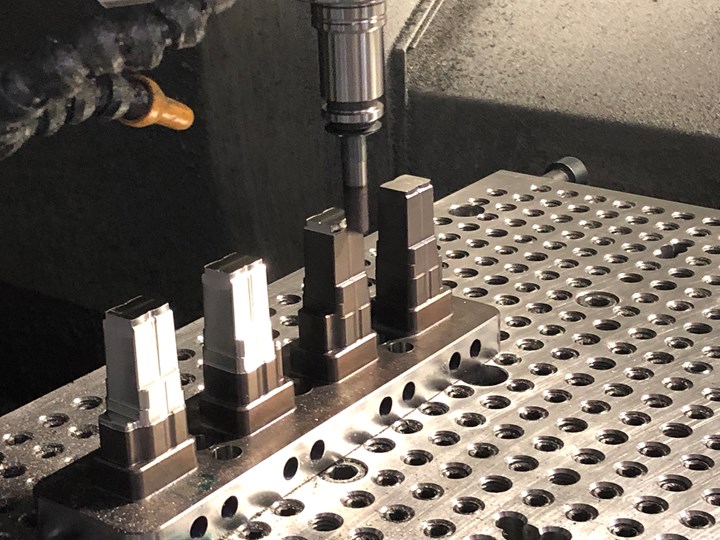

In order to reduce downtime on its EDM and CNC machines when setting up new jobs, moldmaker Kavia Tooling turned to a coordinate measuring machine from Hexagon Manufacturing Intelligence to create an offline zero transfer system ahead of the manufacturing process for parts and electrodes.

In order to considerably reduce downtime on its EDM and CNC machines when setting up new jobs, moldmaker Kavia Tooling turned to using a coordinate measuring machine (CMM) from Hexagon Manufacturing Intelligence to create an offline zero transfer system ahead of the manufacturing process for parts and electrodes.

According to Kavia, some components were particularly time-consuming to set up traditionally on machines, and even simple parts meant the machines were idle during set up. Hexagon customized the flexible PC-DMIS software that comes as standard on the company’s measurement devices, enabling the moldmaker to use the software to find offsets at the beginning of the operation.

This meant the machines could cut another job while the setup for the next one was being carried out. Instead of having to put each part on the machine and then set it, Kavia set it on the CMM, which gave the X, Y, Z and U orientation. The moldmaker only has to put the zero transfer plate, which is micron-accurate, into position on the machine, and it knows exactly where the part is.

This can be done with any number of components, thanks to another piece of customized software, which Kavia Tooling devised themselves and which engineers from Hexagon’s CAM system, EdgeCAM, developed for them. EdgeCAM drives seven high-speed CNC mills with spindle speeds varying from 12,000 to 30,000 rpm, and a Sodick EDM.

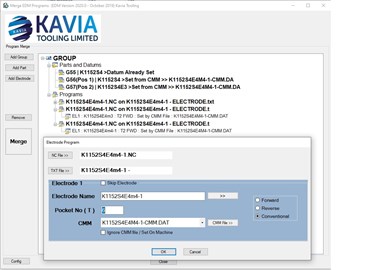

“But it’s no ordinary machining process, thanks to the customized software that we call Merge,” says Kavia Production Director, Mark Cole. “It collates data from all programs for the job and merges them into a single file. It includes the EdgeCAM NC code, datums to set the parts on, zero transfer and cutter tool heights.”

He cites an example when the company was working on two cavity plates on one side of the machine, and four inserts on the other. “We put the individual EdgeCAM CNC programs for each component together into one file, and it all went to the machine as one large program.”

According to the company, the software keeps cutting tools to a minimum, by looking at information such as duplication, length and quality of the tools in all programs. If there are two repeating cutting tools in the individually merged program, it selects the best one for the manufacturing process. It goes through every single NC program and rearranges all the tools accordingly.

The end result of using Merge with the zero transfer fixture plates created on the CMM is a CNC program that can machine several parts at a time without the need to use the machine as a set-up station, as all preparatory operations are carried out offline.

“If we were setting up a component to be square, directly on the CNC machine tool without the CMM, we’d have to ensure it’s perfectly in line with the machine’s axis. Doing that for ten components considerably increases the risk of error, especially where there are overhangs,” Cole says. “But setting them on the CMM means everything is automatically correct, because it tells the machine the angle of each part. To set up six fairly difficult components directly on the machine may take one day, during which time it’s not running. But it’ll only take about an hour on the CMM, and we can be confident that they’ll all be absolutely accurate.”

He says that while the Merge software combines with the CMM zero transfer system to get the best out of their CNC mills, they gain even greater benefits from using it on the Sodick EDM.

Before, the company’s Sodick EDM required them to not only set the electrodes and the part on the machine, but to also program it by hand-typing figures directly into it, leading to errors. When the company developed the Merge software, typing was no longer required since everything was done from the CAD dimensionally, and all the offsets were set on the CMM, which meant there was no setting on the machine. The EDM suddenly went from being the largest bottleneck to the fastest machine in the factory.

The Merge software collates all the programs, zero transfers and information about the spark positioning. It works with up to 12 electrodes at a time, bringing all the CNC programs together and identifying the X, Y, Z and U orientation, putting everything together in a format that runs on the Sodick EDM to the correct datum, automatically adjusts the tank height and provides a setting sheet.

The EDM suddenly went from being the largest bottleneck to the fastest machine in the factory.

Merge is proving to be so beneficial for both simplifying and speeding up the work on the Sodick EDM that Kavia Tooling is now developing the software commercially for those machines. “It’s currently being trialed in the field, and we’re aiming to start marketing it shortly,” says Cole.

Related Content

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreMachine Monitoring Platform Improves Machine Utilization, On-Time Delivery

Using data from a machine monitoring platform, Westminster Tool added almost 75 hours of capacity per week by shortening warmups and starting CNC and EDM machines sooner.

Read MoreSoft Wired: Cutting High Taper Angles with Wire EDM

Examine the wire’s properties to determine the right one for achieving the best cut.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More