Complete Mold Filling Analysis Helps with Automotive Design Challenges

Intier Automotive relies on CAE consulting for automotive design and innovation.

Intier Automotive, the interiors company of Magna International, is an innovative leader in the development and manufacture of vehicle interior and vehicle components and systems for the global automotive industry. The company designs and manufactures automotive interior components—including instrument panels, door panels, lift (or swing) gates, quarter panels, seats, overhead systems and consoles.

The company employs people throughout North America, Europe, Brazil, Japan and China. It has 74 production facilities, 15 product development, engineering and testing centers, and 21 sales/purchasing offices. At its Intertech facility located in Nashville, IL, Intier manufactures door panels, quarter panels, lift gates, and instrument panels with injection molding and low pressure molding processes, as well as full assembly operations.

Challenges Solved with Computer-Aided Engineering Services

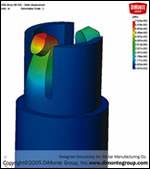

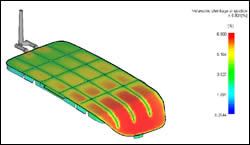

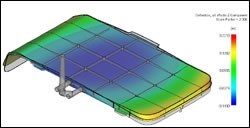

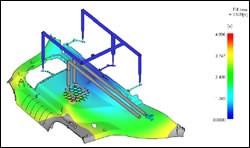

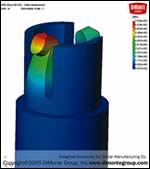

Over several years, the Intertech operations have relied on CAE Services to provide in-depth, computer-aided engineering consulting services using Moldflow Plastics Insight (MPI) software. CAE Services have provided filling, packing, cooling and warpage analyses on many vehicle platforms.

According to Jim Betters, Intier’s processing technology and tooling manager, “CAE Services have provided complete mold filling analysis for us on many applications on several vehicle platforms. They have performed mold filling, packing, cooling and warp analyses.”

He says that for any given part, Intier has to be very cognizant about proper gate locations, optimum number of gates and the ability to fill a complicated cavity within the capability of the molding system.

“We look to CAE Services to help us with these challenges,” Betters adds. “The design, processability and long-term manufacturability of a tool starts with the basic understanding of how a mold will fill and how the stresses and temperature profile of the tool and material during processing will affect part appearance and dimensional characteristics. Working with CAE Services, we obtain an accurate understanding of the expectations of the parts to be produced for a new mold with the analysis.

“We decided to have the mold filling analysis completed on large tools with multiple gates and complex geometry to incorporate greater efficiency as it helps to eliminate trial-and-error experimentation with gate locations, and to determine in advance where we had shortcomings in our initial tool design scheme. We also wanted to examine relocation of water lines to address hot spots and awareness of unusual knit line locations and high pressure to fill situations,” continues Betters.

He and his team expected the analysis to provide reasonable prediction of the filling patterns of the tool with the selection of various gating locations and gate designs and/or gate sizes. In addition, they expected the analysis to offer an opportunity to visualize the results of various filling and packing conditions on the end product with respect to warp and clamp tonnage, use the computer simulation to predict the optimum processing condition to create a more efficient tool start-up process, and therefore, enhance confidence in end product quality.

“We were very pleased with the results predicted from the mold filling analysis, even on the most complicated tools,” Betters says. “The predictions of knit line locations, filling pressure, and clamp tonnage correlated extremely accurately.”

Cost Justification

Betters says the cost of working with CAE Services is justified immediately by reducing the time and number of molding trials it takes to obtain first shots off a new tool and first shots of higher quality sooner in the process.

In addition, he says that since they have worked with CAE Services, he can’t recall a single incident in which Intier had to move a gate or add additional gates to solve a processing issue or solve a cosmetic issue. “We were immediately at the processing window and it was up to us to make the minor adjustments to improve part appearance,” Betters explains.

“A tool trial on a large 3,000-ton press operating at the minimum cost per day for the machine alone can be worth the price of employing upfront analysis. Add to that the cost of bringing people from the manufacturing site to the mold shop, material costs and shipping, and you’re looking at some significant numbers for each testing trial. So the cost of the analysis will be justified with the elimination of just one trial,” states Betters.

Related Content

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreCAM Code Is Key to Precision Mold Machining

The intuitiveness of Mastercam’s CAD/CAM interface streamlines training and advanced programming for intricate fishing tackle products from Venom Outdoors.

Read MoreTolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

Read MoreUnderstanding the Elusive Nature of Mold Ventilation

A personal journey of lessons learned about the challenges of poorly designed, understood and executed mold venting.

Read MoreRead Next

Rigorous Mold Tryout: Do Your Homework

If moldmakers strive to understand how an end user will use the mold, they will help their customers become more profitable and more confident in the shop’s abilities leading to a strong partnership.

Read MoreBreaking the Mold in Mold Development

Integrated analysis capabilities streamline mold design.

Read MoreThe Benefits of a Remanufactured CMM in Your Shop

The only way to economically meet the need for a large gantry CMM with an uncommon measuring envelope was to find an existing one, rebuild it and remanufacture it.

Read More